I made a typo above too, had 2 x 25VA secondaries on the brain and typed 25VAC instead of 45VAC.

yeah the molex connectors are a minefield, you can pay stupid money for them, especially in small numbers, we really should have done a GB on them. I got some different and even pricier ones with machined sockets instead of stamped. but the ones you have linked are indeed a bit expensive at digikey, cheaper at mouser.

the main thing to watch if you dont plan on plugging and unplugging a lot is the thickness of the gold plating, this adds a lot to the price if you go for the thicker plate. I personally just buy the expensive sockets, but make my own male pins with hard annealed sterling silver wire that i have heaps of. if anyone would like some of the silver let me know and i'll send with your board. I even have some hard annealed solid 9ct yellow and white gold I was thinking of using for the main outputs lol just because I can. and really actually works out cheaper than the molex haha

yeah the molex connectors are a minefield, you can pay stupid money for them, especially in small numbers, we really should have done a GB on them. I got some different and even pricier ones with machined sockets instead of stamped. but the ones you have linked are indeed a bit expensive at digikey, cheaper at mouser.

the main thing to watch if you dont plan on plugging and unplugging a lot is the thickness of the gold plating, this adds a lot to the price if you go for the thicker plate. I personally just buy the expensive sockets, but make my own male pins with hard annealed sterling silver wire that i have heaps of. if anyone would like some of the silver let me know and i'll send with your board. I even have some hard annealed solid 9ct yellow and white gold I was thinking of using for the main outputs lol just because I can. and really actually works out cheaper than the molex haha

Last edited:

hmm, I dont know about the large heatsink catalogue at DK or mouser. the only way this board can be mounted really is with the sink under the board and it must really be at least 0.60C for 80 degree rise and preferably better. very quiet here, nobody else has done any building? I have done all the SMD soldering for 5 boards and nobody else??

need to get these parts porn pics up, again my day flew by without getting that done and now everything is here pretty much. still waiting on my heatsinks as the drilling pattern for mounting holes was only just finalized, hopefully conrad can still get it done before their break. otherwise I will have to come up with another heatsink for matching if not and really that would be fine, because there is little chance of me being finished matching before then anyway.

one thing I will say WRT heat is that you will not be able to get away with using the floor of a small case, you will make a nice little toaster oven this way. if using the bottom of a case as the sink, it needs to be a biggish case and well ventilated.

need to get these parts porn pics up, again my day flew by without getting that done and now everything is here pretty much. still waiting on my heatsinks as the drilling pattern for mounting holes was only just finalized, hopefully conrad can still get it done before their break. otherwise I will have to come up with another heatsink for matching if not and really that would be fine, because there is little chance of me being finished matching before then anyway.

one thing I will say WRT heat is that you will not be able to get away with using the floor of a small case, you will make a nice little toaster oven this way. if using the bottom of a case as the sink, it needs to be a biggish case and well ventilated.

I'm surprised how quiet it has been as well. I am going to do the SMD soldering this weekend. I'm planning to use the base of my case to spread the head over to two conrad sinks mounted vertically (much like OPC had shown in a sketch a while back). I'm hoping a 5mm-6mm thick aluminum base for my case will do the trick.

sure that should work, but you really will need to make sure there is good transfer to the sinks from the bottom plate. A plate that thick may of course be good enough all by itself depending on the size, perhaps do some calcs to see, as tghis will save a decent amount of money and effort if you can get away with it. as I said anything .55-.60C/watt for 80 degree rise and better will do.

Hi Guys,

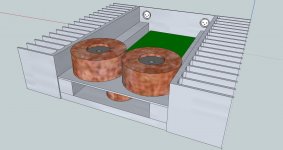

I drew up a quick model of what my plans are for the DAC, so everyone can get an idea of where I'm going with mine.

For reference, the bottom plate is 0.5" thick, the whole DAC is about 12.5"wide by 12.25" deep and 3" high

I'm going to use Aavid 65535 extrusions cut to 3" lengths for the sides.

The 1" by 1" bars will transfer heat from the bottom plate to the sinks, and the whole thing should run pretty cool.

The .zip attachment is the Google Sketchup file.

Cheers,

Owen

I drew up a quick model of what my plans are for the DAC, so everyone can get an idea of where I'm going with mine.

For reference, the bottom plate is 0.5" thick, the whole DAC is about 12.5"wide by 12.25" deep and 3" high

I'm going to use Aavid 65535 extrusions cut to 3" lengths for the sides.

The 1" by 1" bars will transfer heat from the bottom plate to the sinks, and the whole thing should run pretty cool.

The .zip attachment is the Google Sketchup file.

Cheers,

Owen

Attachments

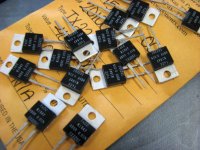

parts hoarding

here is SOME of the parts that are here, i'm running out of room. the last ones are just posted as a matter of interest, they are the SMD Zfoils i'm using in another project, cute hey??

here is SOME of the parts that are here, i'm running out of room. the last ones are just posted as a matter of interest, they are the SMD Zfoils i'm using in another project, cute hey??

Attachments

-

TX220Z 400R group.jpg194.5 KB · Views: 1,738

TX220Z 400R group.jpg194.5 KB · Views: 1,738 -

TX220Z 400R close.jpg192.5 KB · Views: 1,663

TX220Z 400R close.jpg192.5 KB · Views: 1,663 -

TX220Z 400R 0.0075% match web.jpg134.4 KB · Views: 1,617

TX220Z 400R 0.0075% match web.jpg134.4 KB · Views: 1,617 -

reg section cutoff web.jpg170.3 KB · Views: 764

reg section cutoff web.jpg170.3 KB · Views: 764 -

thorsten D1 web.jpg176.3 KB · Views: 774

thorsten D1 web.jpg176.3 KB · Views: 774 -

uber parts gaggle.jpg206.2 KB · Views: 1,576

uber parts gaggle.jpg206.2 KB · Views: 1,576 -

Zfoil SMD ASMP identical lorez.jpg135.9 KB · Views: 643

Zfoil SMD ASMP identical lorez.jpg135.9 KB · Views: 643 -

ASMP Zfoil SMD 3 web lorez.jpg122.8 KB · Views: 484

ASMP Zfoil SMD 3 web lorez.jpg122.8 KB · Views: 484

protection diodes for the input (Z1-8). the little tipis he was talking about and you can see in my pics. no extra Zfoils sorry mate

totally understand about wanting to use what youi have already, especially for things like transformers where big shipping fees are often involved.

guys I have a bit of bad news, heard back from Conrad, the pricing turned out OK considering there is 16 holes that need tapping in each sink, although I will need to get a bit more from you guys for the tapping, to me its definitely worth the price to get them tapped professionally in exactly the right places, but the problem is they cannot deliver until the 2nd week of Jan because they are going on holidays

this will not really cause much delay, as with this time of year and family commitments it would be a miracle if I was finished all the matching sooner than 3-4 weeks (should be pretty good timing actually), i'm praying they can deliver my matching rig sink straight away, they should be able to as it should be in stock and needs nothing done (2 lots of shipping is very annoying though) without it I will have to buy something for that somewhere else.

they are being tapped for M3 metric hardware, so if you cannot get this locally and would like me to get it for you let me know.

Template cost - $95 (good for about 30 sinks)

Setup fee - $25

Drilling/tap - $8 ea sink

Heatsink - $17 ea sink

So, for the 5 h/sinks, it comes out to be $95 + $25 + (5 x 8) + (5 x 17) = $235, or $47 ea.

totally understand about wanting to use what youi have already, especially for things like transformers where big shipping fees are often involved.

guys I have a bit of bad news, heard back from Conrad, the pricing turned out OK considering there is 16 holes that need tapping in each sink, although I will need to get a bit more from you guys for the tapping, to me its definitely worth the price to get them tapped professionally in exactly the right places, but the problem is they cannot deliver until the 2nd week of Jan because they are going on holidays

this will not really cause much delay, as with this time of year and family commitments it would be a miracle if I was finished all the matching sooner than 3-4 weeks (should be pretty good timing actually), i'm praying they can deliver my matching rig sink straight away, they should be able to as it should be in stock and needs nothing done (2 lots of shipping is very annoying though) without it I will have to buy something for that somewhere else.

they are being tapped for M3 metric hardware, so if you cannot get this locally and would like me to get it for you let me know.

Template cost - $95 (good for about 30 sinks)

Setup fee - $25

Drilling/tap - $8 ea sink

Heatsink - $17 ea sink

So, for the 5 h/sinks, it comes out to be $95 + $25 + (5 x 8) + (5 x 17) = $235, or $47 ea.

Last edited:

- Home

- Source & Line

- Digital Line Level

- Build Thread - A New Take on the Classic Pass Labs D1 with an ESS Dac