Planet 10: "So the closer to square shape the stronger the panel resonance? "

That was interesting. Then one should aim for narrow rectangular panel shapes. perhaps of different width?

Planet 10: "In a subwoofer you usually don't have to worry as long as panel resonant modes are higher than your passband."

Now I lost it again. Not worry about what? You mean there are bigger problems with the design than the panel resonances?

Not worry about what? You mean there are bigger problems with the design than the panel resonances?

That was interesting. Then one should aim for narrow rectangular panel shapes. perhaps of different width?

Planet 10: "In a subwoofer you usually don't have to worry as long as panel resonant modes are higher than your passband."

Now I lost it again.

Planet 10: "So the closer to square shape the stronger the panel resonance? "

Not quite: the potential for resonance becomes greater. If we had a circular panel all distances would be the same, and you can get circular modes. The same happens to a lesser extent with squares. The rule i use (and ignore sometimes), is that any brace should create subpanels with higher aspect ratio than the original panel.

Then one should aim for narrow rectangular panel shapes. perhaps of different width?

Yes. Avoid 2 subpanels the same. If you can make those narrow rectangles a little trapezoidal even better.

Planet 10: "In a subwoofer you usually don't have to worry as long as panel resonant modes are higher than your passband."

Now I lost it again.Not worry about what? You mean there are bigger problems with the design than the panel resonances?

All panels resonate. If you can get those resonances higher than any sound the subwoofer outputs then there is no energy to excite the panels, so you have no resonance. Hit it with your knuckle or a hammer or something and it may ring like a bell, but if in actual use no energy excites the resonance, there is no resonance.

Pretty easy given the small (relatively) box compared to the wavelengths it produces

dave

the key words here are:

triangulation.

Pentagons work too. Structurally triangles are better than squares or 4 sided polygons.

Divide your rectangular panel into a matrix at 45deg to the edge. Brace following the matrix. Job done. Think of those plastic pallets

this what ive done in my latest protect. 2 holy holey braces perpendicular to eachother, set at diagonals, fixed at rear of baffle. The incorperate a magnet brace, and they equal int depth of box. If u see what i mean. I can post a drwg if u like.

As P10 says square or cuboid bracing creates acoustic problems, BUT it is the most minimally efficient method of bracing. Moving away from cuboid loses bracing strength to wt ratio bt reduces many similar resonances occuring.

triangulation.

Pentagons work too. Structurally triangles are better than squares or 4 sided polygons.

Divide your rectangular panel into a matrix at 45deg to the edge. Brace following the matrix. Job done. Think of those plastic pallets

this what ive done in my latest protect. 2 holy holey braces perpendicular to eachother, set at diagonals, fixed at rear of baffle. The incorperate a magnet brace, and they equal int depth of box. If u see what i mean. I can post a drwg if u like.

As P10 says square or cuboid bracing creates acoustic problems, BUT it is the most minimally efficient method of bracing. Moving away from cuboid loses bracing strength to wt ratio bt reduces many similar resonances occuring.

Last edited:

Many thanks, this place is a well of knowledge. I think then I will go for paralell shelf bracing in this sub. Cutting sharp angles is too difficult with my gear and skills.

For the 20L main speakers that I will also make in ply it seems some prefer instead of bracing to weigh down the panels with ceramic tiles or by gluing bitumen pads. Could you comment on that?

At TNT-audio they have an experiment comparing MDF and plywood -

Cabinet walls and Loudspeaker Energy Preservation - [English] -

saying that "Damped thin-wall birch-ply makes the least midrange colouration ", but he didnt try holey bracing.

For the 20L main speakers that I will also make in ply it seems some prefer instead of bracing to weigh down the panels with ceramic tiles or by gluing bitumen pads. Could you comment on that?

At TNT-audio they have an experiment comparing MDF and plywood -

Cabinet walls and Loudspeaker Energy Preservation - [English] -

saying that "Damped thin-wall birch-ply makes the least midrange colouration ", but he didnt try holey bracing.

... it seems some prefer instead of bracing to weigh down the panels with ceramic tiles or by gluing bitumen pads. Could you comment on that?

Counter productive in my box building philosphy.

dave

If the boxes are using thinner stock, such as 12mm mdf or ply, the bitumous damping can be useful. bracing in this situation is also useful. I dont subscribe to either of the two camps, as despite what claims bounce around, there is no perfect damping material that will save all woes, and conversely, the rigid bracing ideology fails to conform to expectations. i.e. bitumen and damping can help if not done to excess, and bracing will also help raise panel F1 higher. But damping will not absorb the problem 100% and bracing will not raise fundamantals high enough (for me) using sheet stock and glue. I cannot criticise one camp more than the other. I like the philosophy behind Daves bracing schemes, but i beleive that once the resonance has been raised high enough (for me maybe 2-4k) then a suitable damper should be used to diffuse the energy, even though the panel Q may be higher and less susceptible to excitation.

as with most things a halfway house is the best compromise for most DIYers. My ideal would be a lightly damped, integrally braced monocoque, but this is difficult in a DIY scenario.

as with most things a halfway house is the best compromise for most DIYers. My ideal would be a lightly damped, integrally braced monocoque, but this is difficult in a DIY scenario.

Last edited:

no I may not have explained clearly Kaktus, my fault! the ideal for would be to raise the resonant frequency of the panel high enough that it is not excited by the loudspeaker. 2khz+ would be a nice target to aim for since then there are already less likely to be excited. With a correct level of damping then they can be removed or attenuated even better (In My Opinion). in practice 2k would be difficult, or maybe unrealisable with sheet wood materials.

Dave and many others are in the 'increased panel stiffness' camp, where the aim is to brace a panel as efficiently as possible to raise the fundamental resonant frequency as high as practically possible, and I think im correct in saying that also by minimising the mass added in the act of bracing. I dont want to speak for Dave, but im sure he will correct me if i am wrong in what ive just said

the other camp is the 'BBC thin wall heavy damped' philosophy.

To me BOTH have their valid arguements, but i simply believe that SOME level of panel damping is always necessary, no matter how stiff a panel may be.

What Dave links RE panel bracing where the brace bisects the panel, is correct. expanding upon this and dividing the panel along the longest width say with 3 braces rather than a single, increases stiffness again. dividing this with horizontal braces will increase it further. I dont know the math off the cuff (Dave is much better than me ), but Im fairly sure the stiffness increase from a single full length brace, to a 2nd brace splitting the panel horizontally into quarters is not linear. ie for every successive brace of X strength, the stiffness increase gained reduces. maybe exponentially? Dave? lol

), but Im fairly sure the stiffness increase from a single full length brace, to a 2nd brace splitting the panel horizontally into quarters is not linear. ie for every successive brace of X strength, the stiffness increase gained reduces. maybe exponentially? Dave? lol

That is to say, a single full width vertical(or longest dimension) brace is noteworthy, and efficient in terms of increase in rigidity, for effort expended/mass added in the process/simplicity.

I also like the batten method of bracing a panel, such as fixing 'I-section' or 'T-section' material, to the interior of the panel surface, in a cuboid, or triangular/hexagonal tesselating pattern. I feel this is the most efficient way increasing stiffness, and that parallel wall 'ties' are necessary, but a different structural challenge. Ie with the optimum panel reinforcement one does not HAVE to tie using a full length brace, and one CAN brace parallels at points. I also believe corner jointing is especially important, and i think most if not all speaker builders agree in that importance. Corner reinforcement, is probably just as important.

Dave and many others are in the 'increased panel stiffness' camp, where the aim is to brace a panel as efficiently as possible to raise the fundamental resonant frequency as high as practically possible, and I think im correct in saying that also by minimising the mass added in the act of bracing. I dont want to speak for Dave, but im sure he will correct me if i am wrong in what ive just said

the other camp is the 'BBC thin wall heavy damped' philosophy.

To me BOTH have their valid arguements, but i simply believe that SOME level of panel damping is always necessary, no matter how stiff a panel may be.

What Dave links RE panel bracing where the brace bisects the panel, is correct. expanding upon this and dividing the panel along the longest width say with 3 braces rather than a single, increases stiffness again. dividing this with horizontal braces will increase it further. I dont know the math off the cuff (Dave is much better than me

That is to say, a single full width vertical(or longest dimension) brace is noteworthy, and efficient in terms of increase in rigidity, for effort expended/mass added in the process/simplicity.

I also like the batten method of bracing a panel, such as fixing 'I-section' or 'T-section' material, to the interior of the panel surface, in a cuboid, or triangular/hexagonal tesselating pattern. I feel this is the most efficient way increasing stiffness, and that parallel wall 'ties' are necessary, but a different structural challenge. Ie with the optimum panel reinforcement one does not HAVE to tie using a full length brace, and one CAN brace parallels at points. I also believe corner jointing is especially important, and i think most if not all speaker builders agree in that importance. Corner reinforcement, is probably just as important.

Last edited:

Category: For What Its Worth

I triangulate my stiffeners. One is visible through each of the driver openings. These are made from hardwood, ~1' inch thick, about 2" crown in the center and tapered to each end. There are 14 distributed in each of those cabinets. There are mid-point cross braces front to back and side to side in the finished work.

They all cross the panel points most susceptible to vibration.

They use a minimum of material.

They are easy to install...glue and pin nails.

I triangulate my stiffeners. One is visible through each of the driver openings. These are made from hardwood, ~1' inch thick, about 2" crown in the center and tapered to each end. There are 14 distributed in each of those cabinets. There are mid-point cross braces front to back and side to side in the finished work.

They all cross the panel points most susceptible to vibration.

They use a minimum of material.

They are easy to install...glue and pin nails.

454: "Increase the wall thickness as high as you can afford"

Youre right in a bigger sense. The cost of housing makes the inner width of the walls to my Stockholm apartment the main limiting factor.

mondogenerator: "To me BOTH have their valid arguements, but i simply believe that SOME level of panel damping is always necessary, no matter how stiff a panel may be."

Perhaps there is some way damping that is easy to put in and take away to experiment? or I could do left speaker with and right speaker without damping.

For the sub the inner height will be 56cm (width: 34cm, depth: 43cm). With a 30cm speaker on top of front baffle it means only some 25cm height below the hole in the baffle. Is it any idea to squeeze in two horizontal shelfs there? perhaps instead one holey horizontal shelf just below the speakers hole and then another one above (which means it will not be full length since the basket is in the way and Planet 10 have strong opinions against it)?

Youre right in a bigger sense. The cost of housing makes the inner width of the walls to my Stockholm apartment the main limiting factor.

mondogenerator: "To me BOTH have their valid arguements, but i simply believe that SOME level of panel damping is always necessary, no matter how stiff a panel may be."

Perhaps there is some way damping that is easy to put in and take away to experiment? or I could do left speaker with and right speaker without damping.

For the sub the inner height will be 56cm (width: 34cm, depth: 43cm). With a 30cm speaker on top of front baffle it means only some 25cm height below the hole in the baffle. Is it any idea to squeeze in two horizontal shelfs there? perhaps instead one holey horizontal shelf just below the speakers hole and then another one above (which means it will not be full length since the basket is in the way and Planet 10 have strong opinions against it)?

i wouldnt like to say if you have enough room for the brace you describe, but i do think a vertical brace may be better, even if that means making a cutout for the woofer. Failing that any almost any bracing can help if done properly. It takes time adjusting damping material, but ive used brown bread damping sheet. Bitumen base with alu foil. I warm it slightly to apply, and it holds ok. Even so it can be removed relatively easily ie needed. Felt or wool lining is good for absorbing reflected sound, but does little to damp panel resonance.

I have a similar problem. I wanted to have a vertical brace in a different plane. Centre of baffle to rear panel, including a magnet brace. Fairly P10/Woden inspired i guess. If u can fit 2 or more horizontal braces in the right places, then the difference with a single vertical brace, i feel would be minimal.

I have a similar problem. I wanted to have a vertical brace in a different plane. Centre of baffle to rear panel, including a magnet brace. Fairly P10/Woden inspired i guess. If u can fit 2 or more horizontal braces in the right places, then the difference with a single vertical brace, i feel would be minimal.

Last edited:

Does it matter if the damping goes on the inside or the outside? For a speaker test bed, aesthetics should be the least of your worries.454: "Increase the wall thickness as high as you can afford"

Youre right in a bigger sense. The cost of housing makes the inner width of the walls to my Stockholm apartment the main limiting factor.

mondogenerator: "To me BOTH have their valid arguements, but i simply believe that SOME level of panel damping is always necessary, no matter how stiff a panel may be."

Perhaps there is some way damping that is easy to put in and take away to experiment? or I could do left speaker with and right speaker without damping.

For the sub the inner height will be 56cm (width: 34cm, depth: 43cm). With a 30cm speaker on top of front baffle it means only some 25cm height below the hole in the baffle. Is it any idea to squeeze in two horizontal shelfs there? perhaps instead one holey horizontal shelf just below the speakers hole and then another one above (which means it will not be full length since the basket is in the way and Planet 10 have strong opinions against it)?

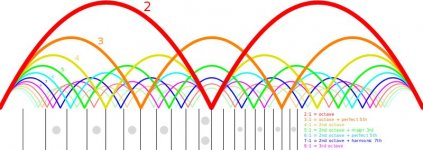

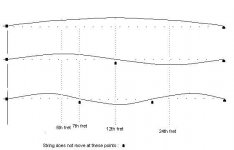

huh... a brace is not really used as a panel stiffener, it does that but that is not why it works, it bisects the surface in the same way your finger does when you press down on a guitar fret board, put your finger half way down the string and you rase the pitch one octave. If the open panel primary resonance is say 500Hz and you bisect it once with a vertical brace you get two panels with primary resonance of 1kHz bisect those vertically and you get four panels with primary resonances of 2kHz.

technically two vertical braces on 3rd's will rase the panel resonance more than an X brace, as an X brace only moves the resonance one octave and the two vertical braces on 3rd's rase the panel resonance one octave + perfect 5th.

raising the resonances as much as possible then damping (impedience mismatch) the open areas with something heavy and flexible like pond liner glued down with silicone has worked well for me.

technically two vertical braces on 3rd's will rase the panel resonance more than an X brace, as an X brace only moves the resonance one octave and the two vertical braces on 3rd's rase the panel resonance one octave + perfect 5th.

raising the resonances as much as possible then damping (impedience mismatch) the open areas with something heavy and flexible like pond liner glued down with silicone has worked well for me.

Attachments

mondogenerator: "i wouldnt like to say if you have enough room for the brace you describe, but i do think a vertical brace may be better,"

Planet 10 said the same thing I think. But why shouldnt it be more effective to brace the bigger surface (the box will be higher than it is wide)?

revboden: " a brace is not really used as a panel stiffener, it does that but that is not why it works, it bisects the surface in the same way your finger does when you press down on a guitar fret board"

That was interesting. I thought the braces also weakened the vibrations some dB.

Planet 10 said the same thing I think. But why shouldnt it be more effective to brace the bigger surface (the box will be higher than it is wide)?

revboden: " a brace is not really used as a panel stiffener, it does that but that is not why it works, it bisects the surface in the same way your finger does when you press down on a guitar fret board"

That was interesting. I thought the braces also weakened the vibrations some dB.

... the ideal for would be to raise the resonant frequency of the panel high enough that it is not excited by the loudspeaker.

A huge factor here is the energy available to feed a resonance, Physics says that the energy available decreases with the square of the frequency. There are further factors that one can use to argue that in a speaker it is actually decreasing by the 4th power of the frequency.

http://www.diyaudio.com/forums/cons...erials-build-speakers-out-77.html#post2562940

expanding upon this and dividing the panel along the longest width say with 3 braces rather than a single, increases stiffness again. dividing this with horizontal braces will increase it further.

Actually the horizontal brace likely does not improve things significantly.

What bracing does is reduce the span across which the panel can resonant. The short dimension dominates. The relationship here is linear, halve the distance double the frequency. (edit: i see revboden beat me to that)

dave

I like the method where you increase the wall thickness as high as you can afford.

At the possible penalty of increased energy storage (and later release), particularily with homogeneous materials

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Discussion on what materials to build speakers out of