I don't think wire wool is the right stuff to use as you can't get it flat. You need the surface to be flat to get good reflections, use a sanding block.

Have you tried looking for high grit paper can be bought online? Also look for automotive paint suppliers rather than car accessory shops in your town.

Have you tried looking for high grit paper can be bought online? Also look for automotive paint suppliers rather than car accessory shops in your town.

I don't have problem with flatness, it's already flattened down with 600 sand paper and a sander. I tried with wool and I think I got rid of the scratches, but the problem seems to be in the paste and polishing disk. What disk material should I use? I tried with foam and sheep wool to no avail.

0000 steel wool isn't much finer than 1100 grit or so. You need to start with a coarse compound ("rubbing compound") before going to a polishing paste. you'll end up spending a long time with rubbing compound before you're ready for polishing compound. I think the issue is that you aren't sanded smooth enough for compound yet, rather than what you are using to polish.

Have you asked a local auto body shop where they get their fine sandpaper or if they will sell you some? You might find them very helpful if you explain what you are trying to do - especially if you find a really old guy running the shop.

Have you asked a local auto body shop where they get their fine sandpaper or if they will sell you some? You might find them very helpful if you explain what you are trying to do - especially if you find a really old guy running the shop.

From 600 grit, I'd go with 800, 1000 and 1200 first. In a pinch, just go 1000 to 1500 and be prepared to spend a long time on at 1500 before you are ready to polish. Even at 1500 grit, your surface will be semi-gloss at best.

You'll want a polishing compound after the G3.

In case you hadn't heard this tip: a drop of dish detergent in the water tray helps keep the paper from loading. Rinse frequently and change the paper if you see any sign of clogging that you cannot rinse off.

You'll want a polishing compound after the G3.

In case you hadn't heard this tip: a drop of dish detergent in the water tray helps keep the paper from loading. Rinse frequently and change the paper if you see any sign of clogging that you cannot rinse off.

wet & dry emery paper

ZDR,

Look you must find a source of paper finer than 600.

I have used 600 in a few circumstances, & managed eventually to get a good gloss finish, but it depends on a few variables which are hard to specify or control.

If you're not confined to the backwoods this should not be "too hard".

Your local hardware store will have a source, ask them to help by ordering for you, or at least obtain their source & call the supplier. If you're determined & persistent as I believe you are, you will find a way.

Pete

ZDR,

Look you must find a source of paper finer than 600.

I have used 600 in a few circumstances, & managed eventually to get a good gloss finish, but it depends on a few variables which are hard to specify or control.

If you're not confined to the backwoods this should not be "too hard".

Your local hardware store will have a source, ask them to help by ordering for you, or at least obtain their source & call the supplier. If you're determined & persistent as I believe you are, you will find a way.

Pete

Guys, I found all papers on ebay, so I will give it a go. In parallel, I will be enhancing my lazy man's gloss technique.

Yesterday, I spray painted one speaker while the other one was rollered before, so that I can compare the two. Roller did a great job in gloss and left no marks. Spray can left some micro orange peel traces which reduced the reflection sharpness. Roller is also more fogiving when it comes to grit. I could probably get away with 600. Spray layer shows every tiny scratch and would require at least 1200 to smooth things up. I just don't understand why is there more dirt in the roller layer... I wonder if it's in the can itself?

Yesterday, I spray painted one speaker while the other one was rollered before, so that I can compare the two. Roller did a great job in gloss and left no marks. Spray can left some micro orange peel traces which reduced the reflection sharpness. Roller is also more fogiving when it comes to grit. I could probably get away with 600. Spray layer shows every tiny scratch and would require at least 1200 to smooth things up. I just don't understand why is there more dirt in the roller layer... I wonder if it's in the can itself?

Nice.

You must have really rolled a thick coat to fill scratches. Try spraying a little thicker coat from a little farther away. A little drying retarder might help prevent the orange peel on the sprayed finish.

It's really going to hurt when you first hit it with sandpaper to bring it up to a mirror gloss.

You must have really rolled a thick coat to fill scratches. Try spraying a little thicker coat from a little farther away. A little drying retarder might help prevent the orange peel on the sprayed finish.

It's really going to hurt when you first hit it with sandpaper to bring it up to a mirror gloss.

back to (g)loss

Back then, I ended up sanding again and finishing speakers with spray paint. I could not get rid of small particles which were driving me crazy, when applied with either brush or roller.

Now I am building a guitar, and trying to do give a gloss another shot. I have rather cheap factory built Ibanez in black piano gloss finish, and I cannot keep wondering: how the f*** they do it?? I'd have to (sand&paint&dry)*n for months to get close to that finish, and I am sure they just spray it couple of times; or is it that they polish it too?

I gave a brush&can one last go: after diluting the paint with approx 20% thinner, I ran it through a very fine paper filter: 1dl of paint took 1 hour to get through, so you can imagine the filter density. I am sure no particles made it through, and yet, after applying the paint, there they were again. Less, but still there.

So, I just want to know: how the piano/guitar/speaker manufacturers do it?

Back then, I ended up sanding again and finishing speakers with spray paint. I could not get rid of small particles which were driving me crazy, when applied with either brush or roller.

Now I am building a guitar, and trying to do give a gloss another shot. I have rather cheap factory built Ibanez in black piano gloss finish, and I cannot keep wondering: how the f*** they do it?? I'd have to (sand&paint&dry)*n for months to get close to that finish, and I am sure they just spray it couple of times; or is it that they polish it too?

I gave a brush&can one last go: after diluting the paint with approx 20% thinner, I ran it through a very fine paper filter: 1dl of paint took 1 hour to get through, so you can imagine the filter density. I am sure no particles made it through, and yet, after applying the paint, there they were again. Less, but still there.

So, I just want to know: how the piano/guitar/speaker manufacturers do it?

Compressor connection to 230 VAC mains

If you use an extension lead (as most of us often do) to connect your spray-painting compressor.

First check these obvious points:

1) Keep the extension lead unravelled; IE it must not be left partly or wholly coiled up. This is to prevent/limit heat build up in the cable.

2) Check the power point & the extension lead, you intend to use, are rated to supply the amps your compressor can draw. Normally for a home power outlet where the circuit is protected with a 15 amp circuit breaker, you can use up to 15 amps. A 2.5 HP compressor will draw around 10 amps on a 230 VAC supply, & if your circuit is protected with fuses,10amps is about the max you should draw. Your compressor will be labelled with the max current draw.

The extension lead is less certain. If you have only a standard size cable I'd recommend not using beyond 10 amps. However "heavy duty" extension leads are commonly available, & should carry 15 amps.

If your circuit breaker or fuses "blow" during your work, do not simply "reset & continue", rather determine the problem or have the matter investigated.

If you use an extension lead (as most of us often do) to connect your spray-painting compressor.

First check these obvious points:

1) Keep the extension lead unravelled; IE it must not be left partly or wholly coiled up. This is to prevent/limit heat build up in the cable.

2) Check the power point & the extension lead, you intend to use, are rated to supply the amps your compressor can draw. Normally for a home power outlet where the circuit is protected with a 15 amp circuit breaker, you can use up to 15 amps. A 2.5 HP compressor will draw around 10 amps on a 230 VAC supply, & if your circuit is protected with fuses,10amps is about the max you should draw. Your compressor will be labelled with the max current draw.

The extension lead is less certain. If you have only a standard size cable I'd recommend not using beyond 10 amps. However "heavy duty" extension leads are commonly available, & should carry 15 amps.

If your circuit breaker or fuses "blow" during your work, do not simply "reset & continue", rather determine the problem or have the matter investigated.

how the f*** they do it?? I'd have to (sand&paint&dry)*n for months to get close to that finish, and I am sure they just spray it couple of times; or is it that they polish it too?

They don't just spray it a couple of times, that's for sure and yes, they polish it.

It might be airborne dust that is settling in your paint job. Use a faster drying paint and apply in a dust free zone.

Consider dipping for a small item like a guitar body - it can be smoother than spraying.

When paint is sprayed after being filtered as fine as you have, it's not the paint that's causing the "particles".

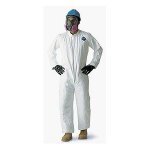

Its the dust that's settling during and after spraying. Try building a temporary spray booth out of NEW el cheapo plastic drop cloths with a moist tarp on the floor. When I spray I wear a Tyvek coveralls suit and latex gloves along with a spray hood.

I still get dust nibs that have to be buffed out. That's just how it is.

That's just how it is.

Ron

Its the dust that's settling during and after spraying. Try building a temporary spray booth out of NEW el cheapo plastic drop cloths with a moist tarp on the floor. When I spray I wear a Tyvek coveralls suit and latex gloves along with a spray hood.

I still get dust nibs that have to be buffed out.

Ron

Attachments

I've heard but never tried with paint finishing that an "Ionizer" will help keep airborne dust particles down. They are used to help people with allergies to dust and pollen. They are not expensive so might be worth a go.

Very "dry" air helps maintain a healthy supply of airborne particles and any sort of carpet/cloth/rug/felt around you. Skin flakes too....unless you are a Lizard!

Very "dry" air helps maintain a healthy supply of airborne particles and any sort of carpet/cloth/rug/felt around you. Skin flakes too....unless you are a Lizard!

I've heard but never tried with paint finishing that an "Ionizer" will help keep airborne dust particles down. They are used to help people with allergies to dust and pollen. They are not expensive so might be worth a go.

Very "dry" air helps maintain a healthy supply of airborne particles and any sort of carpet/cloth/rug/felt around you. Skin flakes too....unless you are a Lizard!

Careful. A poorly designed ionizer makes the dust stick to everything, including your lungs.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- A 'how to' for High Gloss Finishing