Hi Guys,

I want to build a Vocal booth for voiceover work, I have a friend that builds studios for radio stations and he is telling me to use rockwool with a plastic sheet over the top with pegboard covered with hessian (on the inside)

I know this design works really well as Ive worked in studios that he has built but im a bit worried about using pegboard on the inside so close to me, Im not sure if it will create a boxy sound.

Would using the hessian straight over the plastic sheet on the rock wool give me a better sound?

Thank you in advance for your advice..

mike

I want to build a Vocal booth for voiceover work, I have a friend that builds studios for radio stations and he is telling me to use rockwool with a plastic sheet over the top with pegboard covered with hessian (on the inside)

I know this design works really well as Ive worked in studios that he has built but im a bit worried about using pegboard on the inside so close to me, Im not sure if it will create a boxy sound.

Would using the hessian straight over the plastic sheet on the rock wool give me a better sound?

Thank you in advance for your advice..

mike

There are studio-acoustics forums where more people may know more.

What you describe sounds like THE usual way to do it. See Gary Owens. While his TV booth was humorous, the booth construction was authentic. Perforated panel over absorbing fuzz is VERY effective. Burlap (hessian) over seems to be a frill.

For "boxy", it also helps if walls are not parallel, although this complicates the construction.

In the US the most common fuzz is fiberglass. Compressed attic batts are much cheaper than for-acoustic fiberglass. Rockwool is similar but I have the idea it is not as good for the thickness? However SNIFF your fuzz. In my garage-loft job I got a roll of Pink Panther with so much stinky binder on it that after a day I took most of it out.

Further small gains by hanging fluffy wool sweaters or hanging wool blankets a bit off the wall. (Acrylic fuzz is OK but not as good as wool.)

Just fuzz will not block outside sounds. (Wrap your head in a blanket: the lawnmower outside is still loud.) If you also need isolation, you need weight(mass). Drywall is usually the best material. Very tiny cracks and gaps will leak more than the panel: tape and mud all seams, weather-strip the door. Wire hole small and with a firm foam stopper.

What you describe sounds like THE usual way to do it. See Gary Owens. While his TV booth was humorous, the booth construction was authentic. Perforated panel over absorbing fuzz is VERY effective. Burlap (hessian) over seems to be a frill.

For "boxy", it also helps if walls are not parallel, although this complicates the construction.

In the US the most common fuzz is fiberglass. Compressed attic batts are much cheaper than for-acoustic fiberglass. Rockwool is similar but I have the idea it is not as good for the thickness? However SNIFF your fuzz. In my garage-loft job I got a roll of Pink Panther with so much stinky binder on it that after a day I took most of it out.

Further small gains by hanging fluffy wool sweaters or hanging wool blankets a bit off the wall. (Acrylic fuzz is OK but not as good as wool.)

Just fuzz will not block outside sounds. (Wrap your head in a blanket: the lawnmower outside is still loud.) If you also need isolation, you need weight(mass). Drywall is usually the best material. Very tiny cracks and gaps will leak more than the panel: tape and mud all seams, weather-strip the door. Wire hole small and with a firm foam stopper.

Attachments

Last edited:

i've seen many a vocal and drum booth lined with this stuff

Tectum Acoustic Wall & Ceiling Panels for Noise Reduction Toronto Canada

Tectum Acoustic Wall & Ceiling Panels for Noise Reduction Toronto Canada

your asking a question about a result that is the consequence of how it's implemented.

if it's a rectangle with parallel surfaces and reflective material it's likely going to have modes in the "boxy" category.

with pegboard i would install it backside out as in the unfinished "backside" facing you to avoid the surface reflection from the shiny finished side.

it would be a bigger chore construction wise but i would make low profile wedges from strips of the pegboard to emulate an anechoic chamber.

if it's a rectangle with parallel surfaces and reflective material it's likely going to have modes in the "boxy" category.

with pegboard i would install it backside out as in the unfinished "backside" facing you to avoid the surface reflection from the shiny finished side.

it would be a bigger chore construction wise but i would make low profile wedges from strips of the pegboard to emulate an anechoic chamber.

Thank you Turk,

The construction will be:

A sheet of acoustic plaster board, a 5mm sheet of neopreen, another sheet of acoustic plasterboard all screwed onto a 4"x2" framework. All the seals filled with mastic from the inside of the frame. 4" of acoustic Rockwool, a sheet of pegboard (as you suggested back to front) with a covering of hessian fabric.

The door is now the weakest part of the construction.

Mike

The construction will be:

A sheet of acoustic plaster board, a 5mm sheet of neopreen, another sheet of acoustic plasterboard all screwed onto a 4"x2" framework. All the seals filled with mastic from the inside of the frame. 4" of acoustic Rockwool, a sheet of pegboard (as you suggested back to front) with a covering of hessian fabric.

The door is now the weakest part of the construction.

Mike

here's a little something you may find useful Construction Techniques for Noise Control in Building

and Studio SOS: Building A DIY Vocal Booth |

and Studio SOS: Building A DIY Vocal Booth |

Last edited:

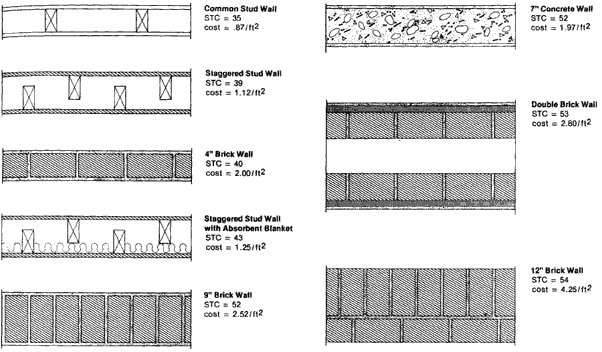

Ideally I wanted 50db quieter inside the booth than outside.

That's thick-brick or heavier.

Hi PRR,

Thank you for the information, im looking for something comparable with the Whisper room spec here: https://www.whisperroom.com/pdf/specs/MDL4260E.pdf

As you can see they are saying a wall slightly thicker than the one I will be building (a few inches thicker) can produce 53db quieter than the surrounding area. Im a voiceover so the lower range doesnt bother me much.

Just to tell you about my setup at the moment, Im in a garage conversion (a room within a room) which is quite quiet anyway, and im looking to build this booth to shut out any extra noise (tv in the next room etc) that could be produced. At the moment I have a metal framework covered with duvets (7 to be precise, this works well for reflected sound) and the noise outside the booth is 39.9db and inside its 34.9db with spikes when my son shouts and the TV gets a bit noisier.

Thank you for the information, im looking for something comparable with the Whisper room spec here: https://www.whisperroom.com/pdf/specs/MDL4260E.pdf

As you can see they are saying a wall slightly thicker than the one I will be building (a few inches thicker) can produce 53db quieter than the surrounding area. Im a voiceover so the lower range doesnt bother me much.

Just to tell you about my setup at the moment, Im in a garage conversion (a room within a room) which is quite quiet anyway, and im looking to build this booth to shut out any extra noise (tv in the next room etc) that could be produced. At the moment I have a metal framework covered with duvets (7 to be precise, this works well for reflected sound) and the noise outside the booth is 39.9db and inside its 34.9db with spikes when my son shouts and the TV gets a bit noisier.

Last edited:

without seeing a blueprint of the construction i would say that the "whisper room" employs the same strategy as i suggested not connecting the inner surfaces to outer or at a minimum using a damped resilient channel.

what sort of ventilation plenums are you planning to build?

i would try to copy the MDL 127.

what sort of ventilation plenums are you planning to build?

i would try to copy the MDL 127.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Vocal Booth Build 4ft X 6ft