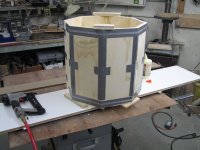

2x8" woofers, 2x4" mids, a tweeter and the enclosure is about 55x15x19 it's this design, I just changed the tweeter. Speaker Design Works

The woodworkers best friend is the Kreg pocket-screw jig:

Kreg Jig(R) K4 - The Easy Way to Build with Wood

Fast, secure, glue or no-glue, fewer clamps required.

Once you use one I bet you will never go back to traditional methods other than for decorative joinery.

Kreg Jig(R) K4 - The Easy Way to Build with Wood

Fast, secure, glue or no-glue, fewer clamps required.

Once you use one I bet you will never go back to traditional methods other than for decorative joinery.

That's hard to do. If you are squeezing out too much glue you may also be damaging the wood.forcing out too much glue

But you still have to fill the holes and those are pretty big holes.Once you use one I bet you will never go back to traditional methods other than for decorative joinery.

I prefer using battens and blind air nailing. Sure you have to have a compressor but I can assemble a cabinet a lot faster than any of the methods mentioned and it's almost foolproof.

Attachments

But you still have to fill the holes and those are pretty big holes.

If you locate the holes on the inside of the cabinet there's no reason to fill them.

I have an assortment of nail guns too and I agree that would be faster, but it doesn't allow one to dry-assemble a cabinet before gluing.

That's the beauty of my method, it's impossible and no wood is harmed in the making of the jointThat's hard to do. If you are squeezing out too much glue you may also be damaging the wood.

I have been using a biscuit joiner for years for speaker boxes. Fast, accurate and secure. Before I bought the joiner, I used a router bit designed for biscuits, to see if they justified buying a dedicated tool. If you have a router, try biscuits. They align the edges automatically, swell when they contact wood glue or water to lock the panels in place, and leave no holes to fill on the outside of the box.

We'll, I can see that these conversations turn into "what oil is best". I'm going to have to stick with the plans for the most part, in this first build. I'll just create headache's that I don't have the skills to resolve if I stray too far. I've got good quality damping material for inside and I will look for places I can add additional bracing, without having a big effect on the cabinet volume. I appreciate everyone's input, but I know try one won't be perfect, if I like the design and drivers, I'll make try two perfect

I’d be inclined to agree with biscuits and / or battens over lock-joint mitres just for ease of set-up. You can use the biscuits on a 45bevel, or even a continuous spline .

As you’ll soon discover with very little research here or elsewhere, the questions of actual materials, or joinery, bracing, damping, etc can be supported from all sides with near religious zeal. There is no single perfect best .

Start from your position of comfort and adventure from there.

Standard MDF is rated at 45lbs / cubic foot, so yeah a single sheet of 3/4 is 90 lbs, and doubling up any ps sos on a larger enclosure will add mass accordingly.

The weight is not the only reason I avoid its use.

As you’ll soon discover with very little research here or elsewhere, the questions of actual materials, or joinery, bracing, damping, etc can be supported from all sides with near religious zeal. There is no single perfect best .

Start from your position of comfort and adventure from there.

Standard MDF is rated at 45lbs / cubic foot, so yeah a single sheet of 3/4 is 90 lbs, and doubling up any ps sos on a larger enclosure will add mass accordingly.

The weight is not the only reason I avoid its use.

I don't know how many of you guys are from California, but the cost of real wood here is staggering. I wouldn't doubt that we have a 400% tree hugger tax on wood; and the selection is worse than the price. I may we wrong about this and only time will tell, but I think I will get more benefit from money spent in better crossover components than I would switching from MDF.

Robert - as I said above, there's more than a bit of zealotry to be discovered in the various camps arguing exactly where to spend the most of your dollars.

FWIW, about a dozen or so years ago I built two pairs of the same design of speaker - happened to be a bipole fullrange MLTL - and played them at a DIY get together. While there wasn't an absolute consensus, I personally preferred the Baltic Birch plywood over the MDF. That was unfortunate, because even though I've been employed in a commercial cabinet making shop for 25yrs, and enjoy lower pricing than probably most folks here, the plywood is more than twice the cost of MDF. Actually the finer grade of Maple veneer faced BB core plywood I'm currently using is over 3 times the cost of premium MDF - and worth every penny AFAIC.

Be careful how many of your premium dollars you invest in boutique audio-phile grade exotic crossover components; in many cases the parts for a higher order 2-way - particularly with impedance compensation or notch filter nodes can cost more than the drivers themselves, and certainly more than the difference in raw materials for the enclosure carcass.

FWIW, about a dozen or so years ago I built two pairs of the same design of speaker - happened to be a bipole fullrange MLTL - and played them at a DIY get together. While there wasn't an absolute consensus, I personally preferred the Baltic Birch plywood over the MDF. That was unfortunate, because even though I've been employed in a commercial cabinet making shop for 25yrs, and enjoy lower pricing than probably most folks here, the plywood is more than twice the cost of MDF. Actually the finer grade of Maple veneer faced BB core plywood I'm currently using is over 3 times the cost of premium MDF - and worth every penny AFAIC.

Be careful how many of your premium dollars you invest in boutique audio-phile grade exotic crossover components; in many cases the parts for a higher order 2-way - particularly with impedance compensation or notch filter nodes can cost more than the drivers themselves, and certainly more than the difference in raw materials for the enclosure carcass.

Last edited:

I hear ya Chris, no $600 speaker cables for me  I just go for good quality, tight tolerance, low resistance Xover parts, that way the calculations are accurate and the speakers are matched. I don't buy into most of the magic, I'm a science guy, I need numbers and evidence. I just want dead on flat, then I'll adjust for the listening environment and my taste. I'm far more comfortable with the electronics than I am the construction end of things. I ordered some L 6" bracket braces today, I think I'm going to add a few to maybe help prevent some resonance from the MDF. I don't think it could hurt, very inexpensive and doesn't take away any enclosure volume to speak of.

I just go for good quality, tight tolerance, low resistance Xover parts, that way the calculations are accurate and the speakers are matched. I don't buy into most of the magic, I'm a science guy, I need numbers and evidence. I just want dead on flat, then I'll adjust for the listening environment and my taste. I'm far more comfortable with the electronics than I am the construction end of things. I ordered some L 6" bracket braces today, I think I'm going to add a few to maybe help prevent some resonance from the MDF. I don't think it could hurt, very inexpensive and doesn't take away any enclosure volume to speak of.

I am really very curious to test passive vs active Xover on this setup. I'm setting up the passive first, but I will no doubt try a full active setup. I don't know if I can do pure apples to apples though; my best amp is 2 channel and my 6 channel amp is a bit underpowered to run a 3 way, I'll see what I can work out. I guess I can at least Bi-amp the passive.

It's ambitious for a first attempt, good luckI'm far more comfortable with the electronics than I am the construction end of things.

It's ambitious for a first attempt, good luck

Thanks, I considered something smaller and easier, but I figured I wouldn't use that kind of build much and that would be a bit of a waste of money. My prerequisites were that I build a musical, stereo listening upgrade that also didn't need subwoofer reinforcement to sound good. something with well documented plans, a proven design and no super fancy, tapers, angles, layers or shaping. I wanted straight cuts. This build came the closest to that and when I did the crossover calculations on my tweeter swap it sealed the deal.

I did all the measurements and mark-up today, I'll be cutting tommorow and hopefully gluing on Monday. If all goes well I will be listening by next weekend. With the CAD drawings for this build; I look at it a little like baking a cake, follow the directions and you can't fail.

Last edited:

I've not used one so I can't know but if you locate them on the inside, what is the screw biting into? Isn't that just too close to the edge of the panel?If you locate the holes on the inside of the cabinet there's no reason to fill them.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Screw & Glue Vs. Clamping?