I use the glue as the air excluding medium for pre-glued hard insulators.

The unglued side needs thermal goop, again to exclude any/all air from the interface.

After a few hours of testing you will usually see that some of the glue has migrated to the edge, because it has flowed under the pressure created by the clamping. This helps to reduce the thickness of the heat insulating effect of the glue. It also helps remove any last hint of air trapped with the glue.

The unglued side needs thermal goop, again to exclude any/all air from the interface.

After a few hours of testing you will usually see that some of the glue has migrated to the edge, because it has flowed under the pressure created by the clamping. This helps to reduce the thickness of the heat insulating effect of the glue. It also helps remove any last hint of air trapped with the glue.

Last edited:

The Silpads are a bit more coin, but I presume I don't need grease with them?

Right, just clean the mating surfaces.

Pass DIY Addict

Joined 2000

Paid Member

I can easily get Silpads and Aluminium Oxide

Best is Alumina for the DIYer.

Those silpads are more for automatic installation or when it needs to go fast and don't have the time to mess with goop

make sure you counter sink the holes on your heat sink.

also, polish the surface since extruded Aluminium surface is far from even..

finally, in my case i've made use of Copper spreader which bolted onto the heat-sink. and transistor is placed over it pressed down by Aluminium plate.

heatsink +

thermal paste+

Copper Spreader+

thermal paste+

Kapton tape+

thermal paste+

transistor

this set up has been working fine for me for past few months.

also, polish the surface since extruded Aluminium surface is far from even..

finally, in my case i've made use of Copper spreader which bolted onto the heat-sink. and transistor is placed over it pressed down by Aluminium plate.

heatsink +

thermal paste+

Copper Spreader+

thermal paste+

Kapton tape+

thermal paste+

transistor

this set up has been working fine for me for past few months.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

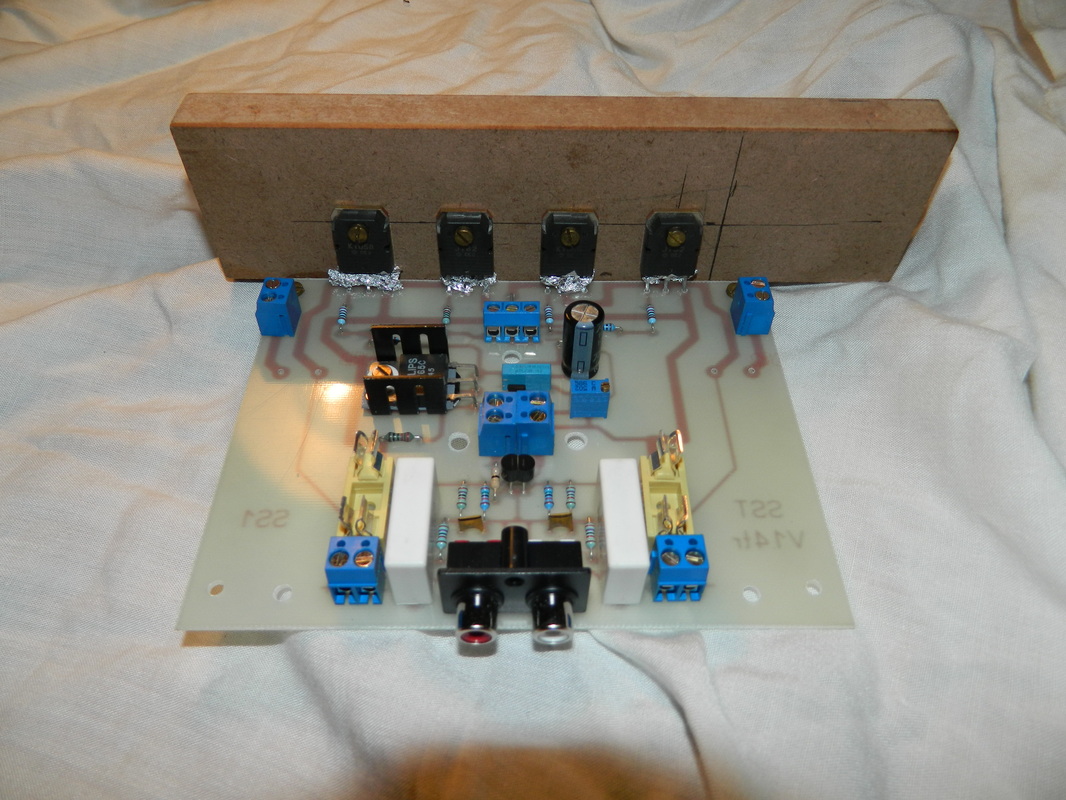

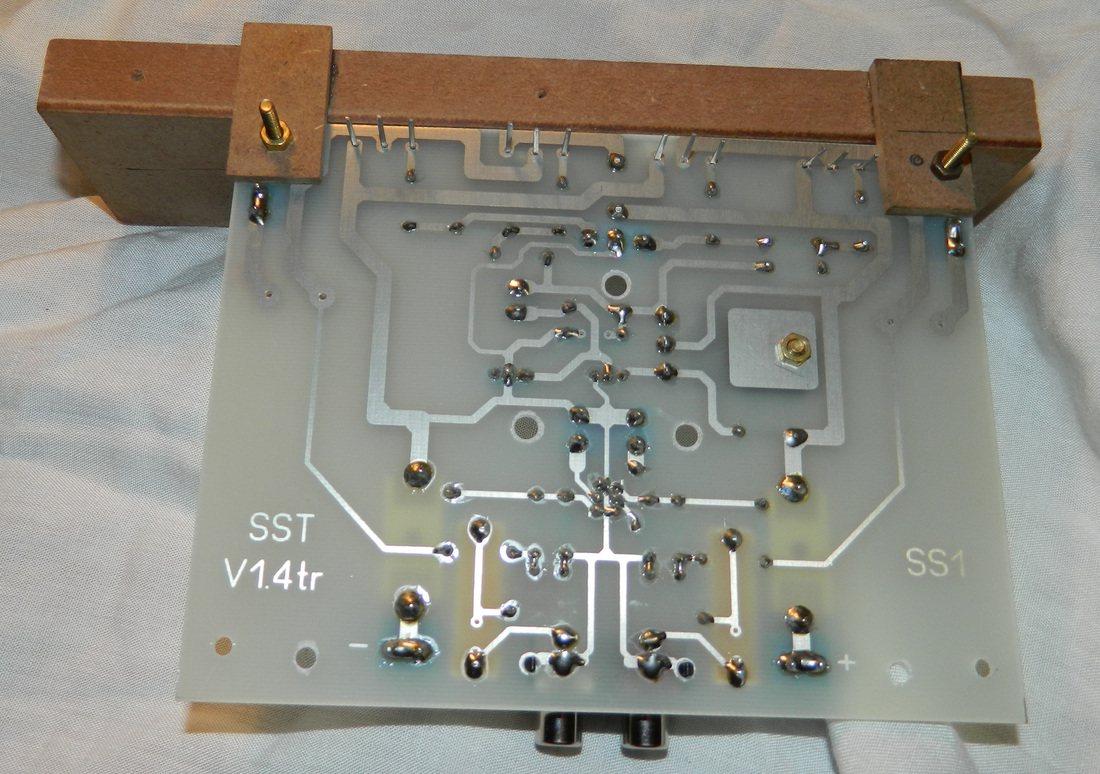

- How to mount transistors to heat sink