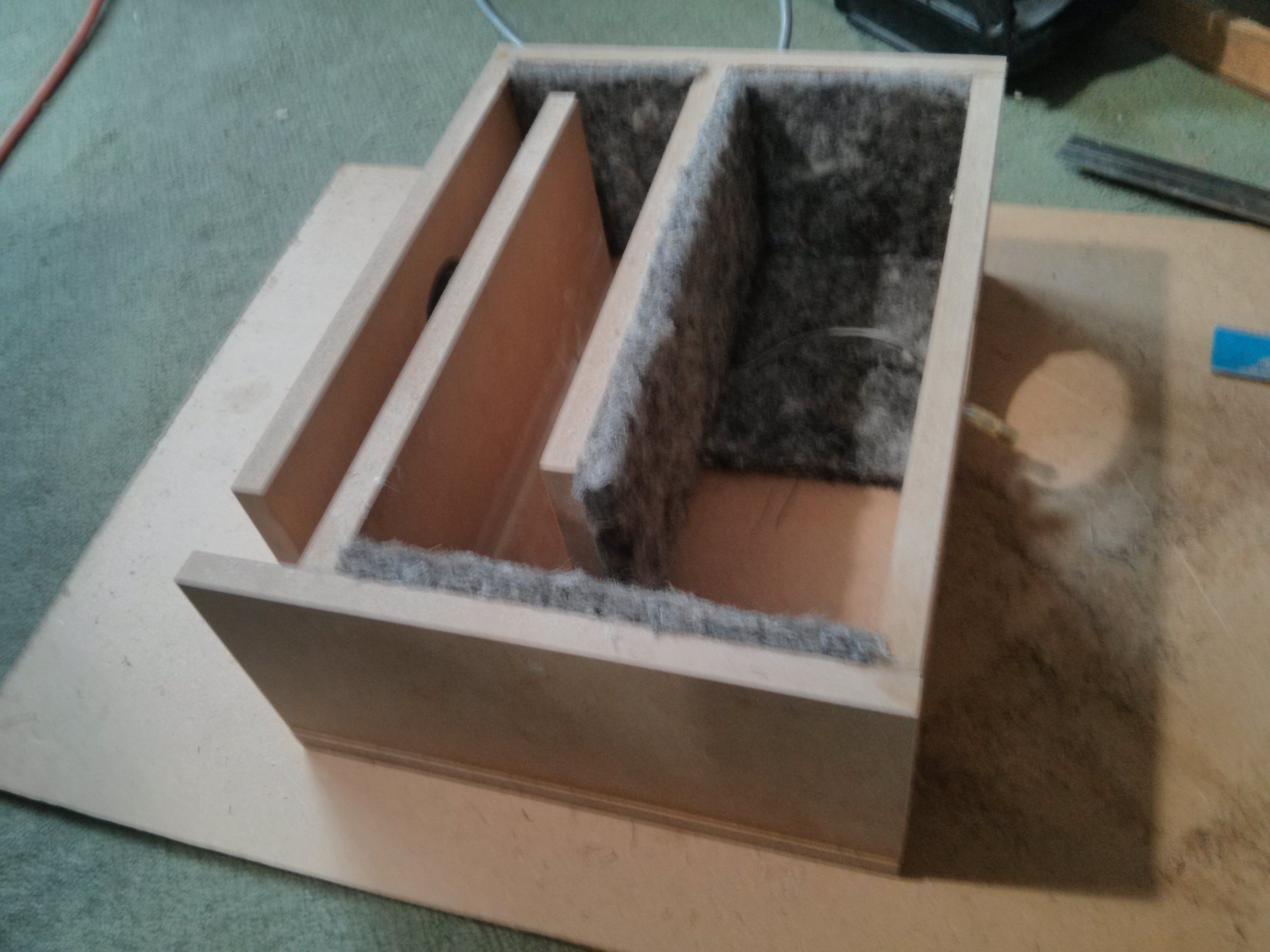

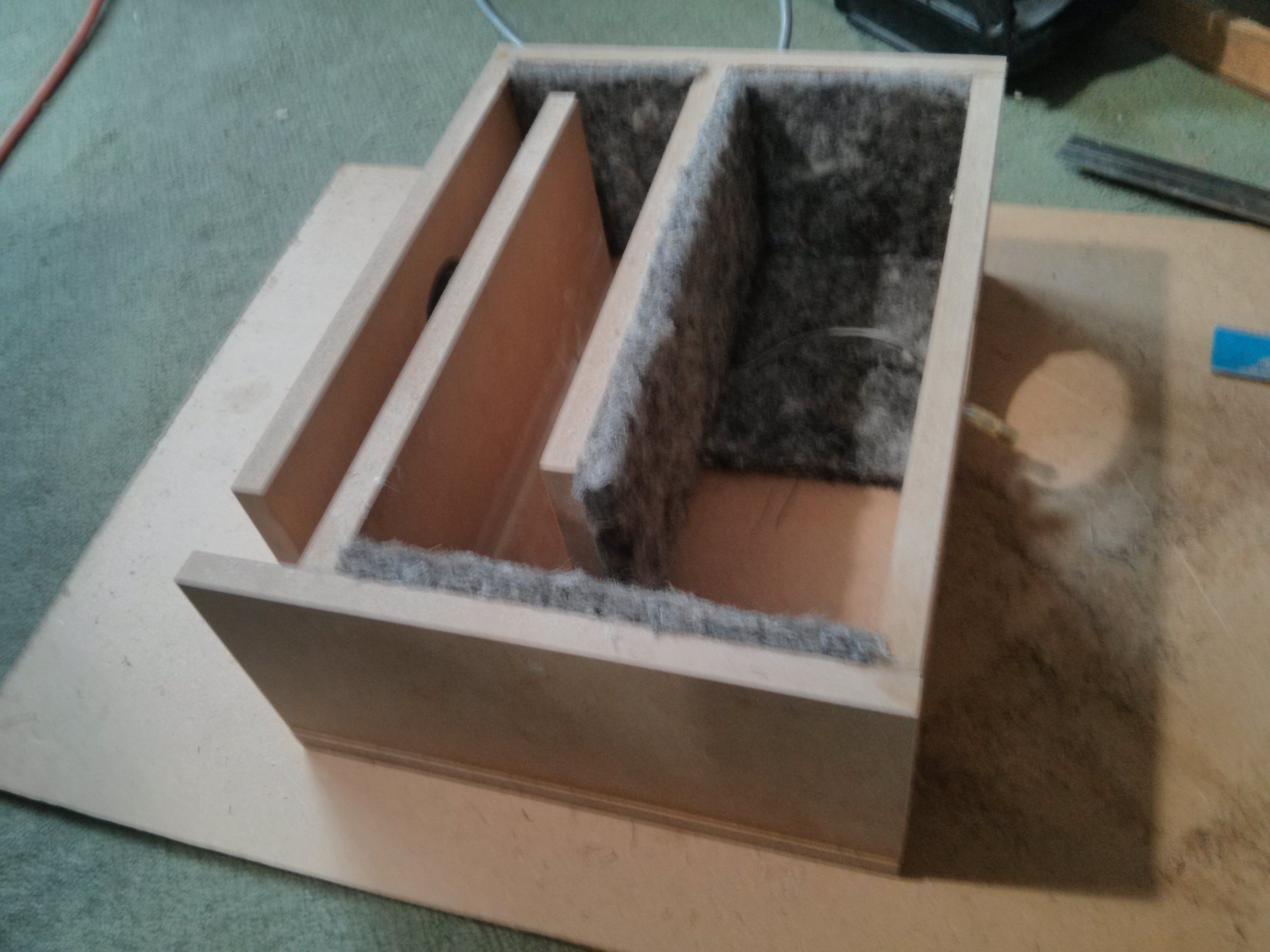

I'm part way through building these. At the moment, I'm trying to juggle fitting internal panels, felt and wadding and wiring to the driver from the rear.

Mostly I'm concerned about the speaker wiring. Trying to decide whether to groove a side panel or the top, and run it under the felt. Or run it down the line... Or drill holes through everything...

Then, the felting. The final bend has one inch height with half inch of felt to be installed, whilst avoiding the speaker terminals etc.

Is there a usual order to approaching this?

J.

Mostly I'm concerned about the speaker wiring. Trying to decide whether to groove a side panel or the top, and run it under the felt. Or run it down the line... Or drill holes through everything...

Then, the felting. The final bend has one inch height with half inch of felt to be installed, whilst avoiding the speaker terminals etc.

Is there a usual order to approaching this?

J.

Ah, read this a little late then.

I'm running the wires along the side panels through grooves in the dividers. Will use decorators caulk or sealant after each panel is fitted and to seal the wiring in.

Speaker binding posts will sit about 1/3 way down the back so they're out of the corners I need to felt.

Current parts list....

12mm MDF cut from B&Q. Check they'll cut such small pieces for you. Usual minimum size before cut is 230x500mm.

MDF Board (Th)12mm (W)606mm (L)1220mm | Departments | DIY at B&Q

Drivers

AuraSound NS3-193-8A 3" Extended Range Driver 8 Ohm

Binding posts

4pcs 4mm Banana Jack Speaker Binding Post Long gold copper Terminals Connectors | eBay

Felt

Loudspeaker damping materials for DIY speaker kits.

Gloop: Titebond 2 wood glue.

J.

I'm running the wires along the side panels through grooves in the dividers. Will use decorators caulk or sealant after each panel is fitted and to seal the wiring in.

Speaker binding posts will sit about 1/3 way down the back so they're out of the corners I need to felt.

Current parts list....

12mm MDF cut from B&Q. Check they'll cut such small pieces for you. Usual minimum size before cut is 230x500mm.

MDF Board (Th)12mm (W)606mm (L)1220mm | Departments | DIY at B&Q

Drivers

AuraSound NS3-193-8A 3" Extended Range Driver 8 Ohm

Binding posts

4pcs 4mm Banana Jack Speaker Binding Post Long gold copper Terminals Connectors | eBay

Felt

Loudspeaker damping materials for DIY speaker kits.

Gloop: Titebond 2 wood glue.

J.

Current parts list....

12mm MDF

Quality plywood/multiply is recommended.

Binding posts

Those look like they are for an amplifier chassis. I would suggest a terminal cup… small is better, as are plastic nuts & not metal. ¾" spacing is standard.

Felt

The 12mm wool felt is next to perfect.

dave

Quality plywood/multiply is recommended.

Those look like they are for an amplifier chassis. I would suggest a terminal cup… small is better, as are plastic nuts & not metal. ¾" spacing is standard.

The 12mm wool felt is next to perfect.

dave

Hi Dave, thanks for advising.

I'm hoping the small size and bracing inherent in the labyrinth will help. Would applying a bitumen based damping sheet help? I have some quantities of dynamat and dynamat extreme lying around.

Terminal cups would make construction easier and maintenance a little more feasible. They seem bulky though. I was concerned at pinching the 25mm line further. (prior to your contribution I hadn't known to search for "terminal cups". I've found some 20mm deep/slim? on eBay).

J.

I'm hoping the small size and bracing inherent in the labyrinth will help. Would applying a bitumen based damping sheet help? I have some quantities of dynamat and dynamat extreme lying around.

12mm ply is about the same as 15mm MDF (MDF has some other issues besides less stiff). If you use 12mm it would be like using 9mm ply, i don't know if that is enuff. So if you use MDF use 15mm.

.Terminal cups would make construction easier and maintenance a little more feasible. They seem bulky though. I was concerned at pinching the 25mm line further

I would not worry about that. They make maintenance (ie cable change) possible.

dave

Almost done...

Felting

Glueing.... I had used Titebond II up to this point. With h/d spray for the felt.

At this point I wanted to ensure no gaps so out came the polyU wood glue.

And as they were earlier.... I couldn't wait any longer to have a proper listen.

They're currently apart again as I needed to flush trim and sand. Primer tomorrow hopefully.

Felting

Glueing.... I had used Titebond II up to this point. With h/d spray for the felt.

At this point I wanted to ensure no gaps so out came the polyU wood glue.

And as they were earlier.... I couldn't wait any longer to have a proper listen.

They're currently apart again as I needed to flush trim and sand. Primer tomorrow hopefully.

Last edited:

As they are now

Finish could be better - but for all my efforts, I'm not the craftsman my Dad was.

Sound is "full", maybe a tad congested.... Bass down to 60hz when positioned properly in the room.

If I compare them to my Tannoy E11s. The Tannoys win! But would cost around £300 in today's money. Notwithstanding the increases in the costs of copper etc for crossovers. Overall, the Tannoys drop a little deeper, sound more open and have a better top end.

Maybe a filter or some more stuffing could improve the Redeyes a little (sprite?). However, I'm very pleased with them as they are. The major concern is turning the wick up too far on the amp and possibly blowing them.

2nd major concern is where to put them. May have to experiment with wall brackets etc...

The grilles are a little heavy handed but not too bad for a 1st attempt.

J.

Finish could be better - but for all my efforts, I'm not the craftsman my Dad was.

Sound is "full", maybe a tad congested.... Bass down to 60hz when positioned properly in the room.

If I compare them to my Tannoy E11s. The Tannoys win! But would cost around £300 in today's money. Notwithstanding the increases in the costs of copper etc for crossovers. Overall, the Tannoys drop a little deeper, sound more open and have a better top end.

Maybe a filter or some more stuffing could improve the Redeyes a little (sprite?). However, I'm very pleased with them as they are. The major concern is turning the wick up too far on the amp and possibly blowing them.

2nd major concern is where to put them. May have to experiment with wall brackets etc...

The grilles are a little heavy handed but not too bad for a 1st attempt.

J.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Woden Redeye build.