That's got to be the most stupid test ever in the history of fan cooling

To test air suction you'd have to create similar pressure. Which would mean ducting the sink and facing the fan to pull air along the fins, at a right angle to how it is kept in the picture.

A thermometer and fan are best accompanied with a bit of common sense.

To test air suction you'd have to create similar pressure. Which would mean ducting the sink and facing the fan to pull air along the fins, at a right angle to how it is kept in the picture.

A thermometer and fan are best accompanied with a bit of common sense.

What direction do CPU fans run?

Push or suck?

Both, sometimes. Buy Online Thermalright Silver Arrow Dual 14cm Fan Cooler in India

Exhausts on the PC case are technically using suction.

It's about airflow over surface area. Direction and suck/blow are immaterial except in conjunction with that specific heatsink and layout.

When watercooling, you can stick fans on both sides of the radiator. The 90 degree suction pattern of a typical fan is then constrained by the edges of the radiator, making airflow equal on both sides.

How do fans on external airconditioner units work? Without exception, almost every single one uses suction.

It comes down to cfm of airflow across n square inches of heatsink surface area.

QFT.

Last edited:

It comes down to cfm of airflow across n square inches of heatsink surface area. Other factors such as in-out and and ambient temp are minor in comparison. Correct me if I'm wrong.

You're wrong. Pressure drop and turbulence matter. BUT is depends what you are trying to achieve. Are you trying to cool a heatsink, or just stir the air around. If its a forced induction heatsink then always best to start with a heatsink designed for that purpose. 99% of DIYers are not in that category tho...

I have experimented a lot with amplifier cooling where active cooling was not part of the original design, only to finally abandon the idea because of poor results or unwanted effects, such as overcooling or uneven cooling.

However, I have found that sucking out is better than blowing in. When a fan sucks the hot air out of the enclosure, fresh air enters from various directions through grilles and openings, thus making a more diffuse and wider air circulation through the enclosure. The opposite principle will compress hot air inside the enclosure and heat up the colder parts before it finds its way out.

The only downside of the first principle is the amount of dust which accumulates inside and in this sense blowing in is better because you can put some kind of filter on the intake side of fan.

However, I have found that sucking out is better than blowing in. When a fan sucks the hot air out of the enclosure, fresh air enters from various directions through grilles and openings, thus making a more diffuse and wider air circulation through the enclosure. The opposite principle will compress hot air inside the enclosure and heat up the colder parts before it finds its way out.

The only downside of the first principle is the amount of dust which accumulates inside and in this sense blowing in is better because you can put some kind of filter on the intake side of fan.

Heatsink cooling is a different issue from internal ventilation.

Compromising the heatsink cooling for better internal ventilation does not sound like a good design compromise.

The fanned heatsink should be enclosed in it's own tunnel to ensure that all the cooling air is "used" to cool the heatsink.

Any leaks should be minimised. Leaks will reduce the volume of air passing across the heatsink AND will reduce the speed of the cooling air-stream AND will reduce the turbulence which is essential to minimising the thickness of the laminar layer.

If internal ventilation is required, then a separate passive, or fan assisted, system should be added that does not compromise the main sink cooling.

Compromising the heatsink cooling for better internal ventilation does not sound like a good design compromise.

The fanned heatsink should be enclosed in it's own tunnel to ensure that all the cooling air is "used" to cool the heatsink.

Any leaks should be minimised. Leaks will reduce the volume of air passing across the heatsink AND will reduce the speed of the cooling air-stream AND will reduce the turbulence which is essential to minimising the thickness of the laminar layer.

If internal ventilation is required, then a separate passive, or fan assisted, system should be added that does not compromise the main sink cooling.

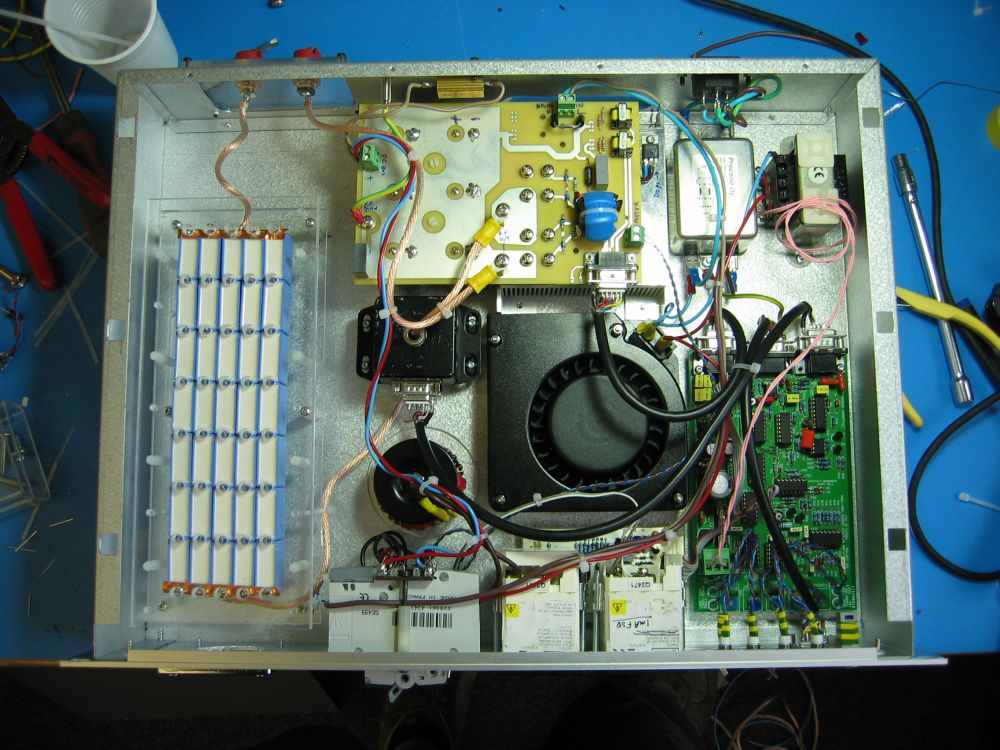

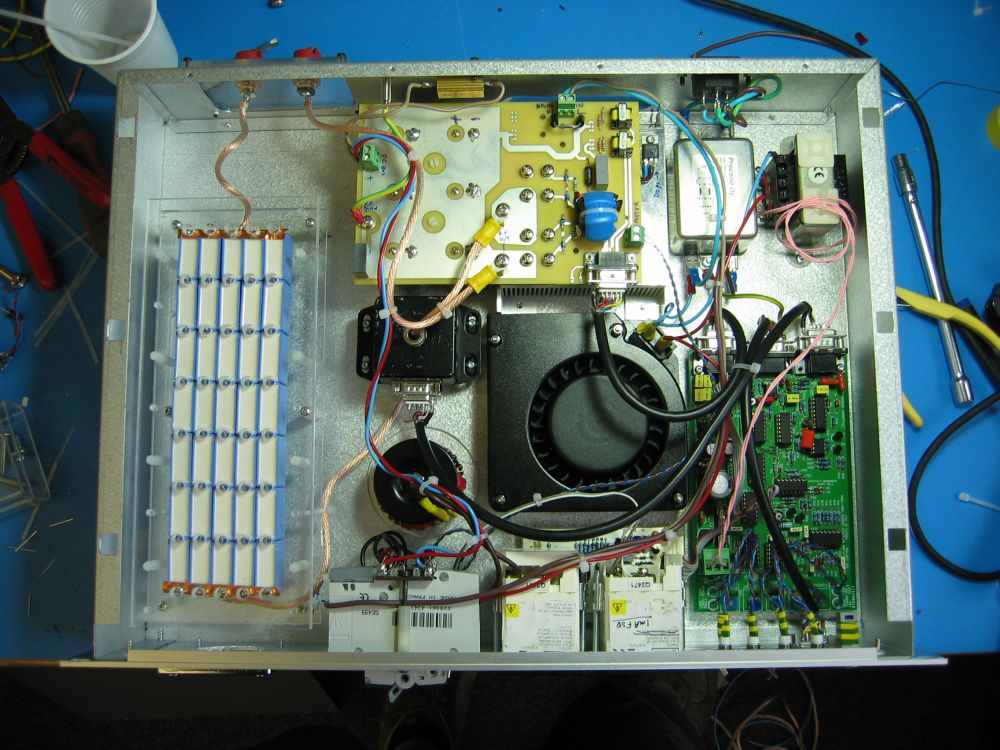

I've seen quite a few systems where a single fan blows air out of the case through a heatsink tunnel, and at the same time creates a negative pressure inside the case so that air is sucked in through other ventilation slots. Examples would be Crown Macro-Tech amps, Xantrex power supplies, and this high frequency generator I built. The air comes in through an inlet hole in the left hand side of the front panel, where it cools the tank capacitor.

(The gaps between blower outlet and heatsink inlet, and between heatsink outlet and the hole in the back of the case, were closed up before use.)

(The gaps between blower outlet and heatsink inlet, and between heatsink outlet and the hole in the back of the case, were closed up before use.)

after reviewing the referenced links i think i'll try a combination approach small fans to create turbulence near the heatsinks and a larger one to exhaust warm air from the enclosure.

hopefully this won't create to much dust debris accumulation in the enclosure.

there appears to be a divided opinion on dust accumulation with respect to intake or exhaust.

hopefully this won't create to much dust debris accumulation in the enclosure.

there appears to be a divided opinion on dust accumulation with respect to intake or exhaust.

Heatsink cooling is a different issue from internal ventilation

.

Exactly, which is what the OP was about

after reviewing the referenced links i think i'll try a combination approach small fans to create turbulence near the heatsinks and a larger one to exhaust warm air from the enclosure.

hopefully this won't create to much dust debris accumulation in the enclosure.

there appears to be a divided opinion on dust accumulation with respect to intake or exhaust.

Dust is the least of your concerns in thermal design. Pay attention that you create uniform cooling of just the desired parts/components and avoid uneven cooling of drivers/output transistors, +/- branches or L/R channels. That said, you shouldn't create any turbulence at all as this will stray the hot air to other components. I think you need a directed and enclosed air stream. In case you really need active cooling, rather than just bigger heat sinks.

how are heatsink and case ventilation not the same?

if the heatsink is surrounded by warm air within the case does that not reduce the effectiveness of the heatsink?

i do understand the complexity of the question which is why i posted in order to hopefully obtain the wisdom of others.

if the heatsink is surrounded by warm air within the case does that not reduce the effectiveness of the heatsink?

i do understand the complexity of the question which is why i posted in order to hopefully obtain the wisdom of others.

Last edited:

There's nothing you can achieve with peltiers, water cooling and fans that you can't achieve with bigger heatsinks and/or more output devices.

Wrong

Usually fans have more pressure at the outlet side than the inlet side.

Another strange remark.

How the hell can increased air-flow be generated without a positive pressure difference.

Comparable to blowing/sucking fans are conventional propellors and waterjets for ship propulsion.

A standard ship screw operates in a free flowing field : water can flow to the blades from a cross-dimensional area which is larger than the prop diameter.

The waterjet has a propellor which is mounted in a duct, the screw has to suck in the water.

At hull speeds, efficiency of a waterjet is a fraction of the one for a conventional ship screw.

All thanks to losses due to sucking versus blowing.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- fan cooling