Hi All

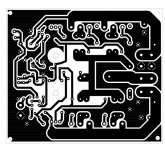

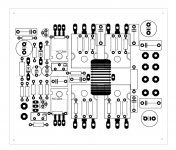

I ahve print a circuit board on a laserprinter for toner transfer, it work but when I do a double sided one i do see the printer is not excact, because of the top pcb is mirorred it do count x 2 when it is not at right 90 degree angles, I hope I say it right.

Have someone do now this? because how bigger the pcb how more problems with pads are out of line.

I have a samsung cheap laser, I think I go find a professional one but it will always be not precise with mirorred angles.

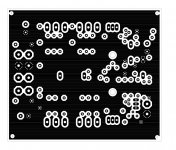

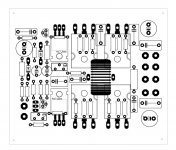

last photo is a transfer test.

regards

kees

I ahve print a circuit board on a laserprinter for toner transfer, it work but when I do a double sided one i do see the printer is not excact, because of the top pcb is mirorred it do count x 2 when it is not at right 90 degree angles, I hope I say it right.

Have someone do now this? because how bigger the pcb how more problems with pads are out of line.

I have a samsung cheap laser, I think I go find a professional one but it will always be not precise with mirorred angles.

last photo is a transfer test.

regards

kees

Attachments

You could try putting some registration marks on each side of the pcb.

Do this in opposite corners.

These could then be lined up when placing transfer.

this is not the problem, real problem is that when i do put marks excactly in line a part of the pad holes do not align, this is because of the laserprinter do not print precisely when one layer (top) is mirrored.

Maybe there is a solution, use a better printer but do now somebody what kind.

I have a big hp printer 1200 dpi postcript, these did wel but is broken.

regards

jees

Be careful that your printer does not "fit to page" , always select "scale=none".

I'm worried that your first images shows thin white horizontal lines ... why?

And when printing both sides on the same sheet at the same time, (only certain way that they match ), one of them must be mirrored by choosing "X flip" or "Y flip" , not by rotating it 90 degrees.

Anyway the example you show does not seem to be a dual layer PCB but a single layer (bottom) + silkscreen (top) and in that case exact location is not *that* critical .

I'm worried that your first images shows thin white horizontal lines ... why?

And when printing both sides on the same sheet at the same time, (only certain way that they match ), one of them must be mirrored by choosing "X flip" or "Y flip" , not by rotating it 90 degrees.

Anyway the example you show does not seem to be a dual layer PCB but a single layer (bottom) + silkscreen (top) and in that case exact location is not *that* critical .

I'm worried that your first images shows thin white horizontal lines ... why?

I've seen that many times in PDF images I've made. They aren't present when printed.

I have a big hp printer 1200 dpi postcript, these did wel but is broken.

1200DPI is not needed. I've none dozens of surface mount boards with extremely small pads and thin traces and I always use 600DPI.

If you want good laser printer see if you can find a Samsung ML-2525W for a reasonable price (or a similar Samsung model). I've had mine for a few years now and absolutely love the thing. I've refilled the starter cartridge 3 times and I've yet to see a single streak or blemish in the prints.

When I do double sided boards I do one side and then drill some pads using a very small bit and use pins in the holes to align the transfer for the other side.

Last edited:

Hi All

I have a samsung laserprinter ML-2165 600 dpi printer./

The lines in the print is not seen in real, I have done a screen capture from the ghostscript I using.

My problem is when print for example a square box and mirror one of them she do not fit anymore but has a mis alignment with this printer, most caused by the printer system who is most plastic. and so I get not the layers aligned, also not when drill smal holes and align it, yes soms pads in wone corner is oke, but on the other side it is not, and how bigger the pcb how more it do mis align.

If I do print both without mirror the top layer everything is fine, so printer mechanics is not exact horizontal of how it needs to be.

When i do single sides pcb then this problem is not a problem.

coming week she bring a HP 4100TN 1200 dpi print I have bought one hour ago, this professional postcript printer do a much better job, I have one but these was defective.

Afcourse a real hp penplotter do the best job, this is real precise when flip one square get lines also then in line.

PS it is a double sided board of a allfet amplifier.

thanks for all the reactions.

regards

kees

I have a samsung laserprinter ML-2165 600 dpi printer./

The lines in the print is not seen in real, I have done a screen capture from the ghostscript I using.

My problem is when print for example a square box and mirror one of them she do not fit anymore but has a mis alignment with this printer, most caused by the printer system who is most plastic. and so I get not the layers aligned, also not when drill smal holes and align it, yes soms pads in wone corner is oke, but on the other side it is not, and how bigger the pcb how more it do mis align.

If I do print both without mirror the top layer everything is fine, so printer mechanics is not exact horizontal of how it needs to be.

When i do single sides pcb then this problem is not a problem.

coming week she bring a HP 4100TN 1200 dpi print I have bought one hour ago, this professional postcript printer do a much better job, I have one but these was defective.

Afcourse a real hp penplotter do the best job, this is real precise when flip one square get lines also then in line.

PS it is a double sided board of a allfet amplifier.

thanks for all the reactions.

regards

kees

Attachments

Last edited:

If you print both sides at the same time, in the same sheet, side by side (of course they must be able to fit side by side in the same sheet !!!) , any mechanical irregularity will happen in both at the same time, so they will still match.

In that case use "X flip" on one to mirror, so the same edge is on top on both.

And print sheet vertical (portrait) , not "landscape" , because no matter what you do on screen, the paper sheet will always be printed along the longest axis.

If it does not fit side by side on the same sheet, then print one per sheet, one X mirrored of course, so although in different sheets they will both travel the same way, both will have the same side on top.

Not as accurate as the other method but better than nothing.

In that case use "X flip" on one to mirror, so the same edge is on top on both.

And print sheet vertical (portrait) , not "landscape" , because no matter what you do on screen, the paper sheet will always be printed along the longest axis.

If it does not fit side by side on the same sheet, then print one per sheet, one X mirrored of course, so although in different sheets they will both travel the same way, both will have the same side on top.

Not as accurate as the other method but better than nothing.

I have the problem that with ghost postcript I can not do two at the same page, so I need a good program what will work, pdf I hear is not precise 100% don,t get why this is in computer age.

maybe you have some idea,s then I go try.

printing one per sheet I have done, these have to much mechanical error, and how bigger the pcb how wurse it get.

But first remove conduit virus, I had 432 infections, spite that I have malwarebytes and avira antivirus, she have now my negative advise on twitter,

regards

kees

maybe you have some idea,s then I go try.

printing one per sheet I have done, these have to much mechanical error, and how bigger the pcb how wurse it get.

But first remove conduit virus, I had 432 infections, spite that I have malwarebytes and avira antivirus, she have now my negative advise on twitter,

regards

kees

Last edited:

Download and run ADWCleaner from Bleeping Computer.

http://www.bleepingcomputer.com/download/adwcleaner

works good against Conduit...

http://www.bleepingcomputer.com/download/adwcleaner

works good against Conduit...

Download and run ADWCleaner from Bleeping Computer.

http://www.bleepingcomputer.com/download/adwcleaner

works good against Conduit...

It is done, by spyhunter, good program find a lot.

If people can advise me how to get the two ps-inverter postscript into one sheet and the do a x flip

I am happy, I can find not much about the postcript. eagle can only export inverted postscript.

thanks for your advise.

regards

Last edited:

I can't say I fully understand the problems you're having, but I used to use a program called PrimoPDF (virtual printer) to invert and do other things.

My problem is that when print double sided prints and mirror the top it is not accurate, holes in pads fit not everywhere, looks like a square in this printer when do one in mirror dont fit anymore.

so printer accuracy sucks, something I did have seen more by laserprinters, it can not be adjusted.

regards and thanks for software.

Have you tried printing on somebody else's Laser?

And have you checked you don't use "shrink to fit", "fit to page", "fit to printable area", etc?

All those settings distort printing.

Use the plainest "do not scale", "do not fit anything" setting.

Worst case, correct it "by hand"

Try this first: draw a 100 mm x 100 mm square using a thin track, say, 12 Mils wide.

Measure it on the actual paper print.

Then invert/flip/mirror it (whatever your software calls it) and print again, in another sheet.

Put some text inside so it's easy to see which is which.

Post both results here.

As in: "standard still measures 100 x 100 , mirrored measures 100 x 96 " or whatever.

You can compensate for that but we need actual numbers.

Also repeat the test on other 2 sheets, to check whether the error is repeatable or random ... in which case there's no cure

And have you checked you don't use "shrink to fit", "fit to page", "fit to printable area", etc?

All those settings distort printing.

Use the plainest "do not scale", "do not fit anything" setting.

Worst case, correct it "by hand"

Try this first: draw a 100 mm x 100 mm square using a thin track, say, 12 Mils wide.

Measure it on the actual paper print.

Then invert/flip/mirror it (whatever your software calls it) and print again, in another sheet.

Put some text inside so it's easy to see which is which.

Post both results here.

As in: "standard still measures 100 x 100 , mirrored measures 100 x 96 " or whatever.

You can compensate for that but we need actual numbers.

Also repeat the test on other 2 sheets, to check whether the error is repeatable or random ... in which case there's no cure

Have you tried printing on somebody else's Laser?

And have you checked you don't use "shrink to fit", "fit to page", "fit to printable area", etc?

All those settings distort printing.

Use the plainest "do not scale", "do not fit anything" setting.

Worst case, correct it "by hand"

Try this first: draw a 100 mm x 100 mm square using a thin track, say, 12 Mils wide.

Measure it on the actual paper print.

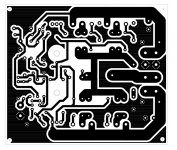

I have here a example what happens in a more extreme way on the photo when mirror one

pcb layer in this case top, what do multiply the printer error twice.

regards

Then invert/flip/mirror it (whatever your software calls it) and print again, in another sheet.

Put some text inside so it's easy to see which is which.

Post both results here.

As in: "standard still measures 100 x 100 , mirrored measures 100 x 96 " or whatever.

You can compensate for that but we need actual numbers.

Also repeat the test on other 2 sheets, to check whether the error is repeatable or random ... in which case there's no cure

Thanks for the reaction.

It seems the laserprinter do when one square in mirror it is not precies straight like the laserdrum is 0.2mm out of line so to say.

tharefore when print without that mirror the sheets match perfect, drills in hole and such.

But I try a big square so it is more easy seen.

Also consider a laserprinter is not precise when mirror one work it drum is out of line, most is because of plastic used in the printer and heat.

I have bought a HP 4100TN printer who is a lot more precise and can be corrected.

thanks for message.

Attachments

Last edited:

I have now include a picture to clear some out, when mirror one layer the printer error get

multiply by two, giving the error with the lines not cover each other anymore, wich give also

drill/pad errors afcourse. I do not now software who can correct it for me, it excists somewhere

even software to spare film by print all on onesheet when it fits, but maybe then the error

will stay, or the both layers on one sheet do cancel out each other.

A real plotter with a pen, then this do not excists she are very precise.

multiply by two, giving the error with the lines not cover each other anymore, wich give also

drill/pad errors afcourse. I do not now software who can correct it for me, it excists somewhere

even software to spare film by print all on onesheet when it fits, but maybe then the error

will stay, or the both layers on one sheet do cancel out each other.

A real plotter with a pen, then this do not excists she are very precise.

I would say your print engine is not aligning properly to the paper. There should be no jaggies with a horizontal or vertical line.

I do not know what to do about it, however, so that is no much use

Are there any options on printer drivers, by any chance? This used to be a problem pre-windows, but I have not had to tweak a printer in 15 years ....

I do not know what to do about it, however, so that is no much use

Are there any options on printer drivers, by any chance? This used to be a problem pre-windows, but I have not had to tweak a printer in 15 years ....

I would say your print engine is not aligning properly to the paper. There should be no jaggies with a horizontal or vertical line.

I do not know what to do about it, however, so that is no much use

Are there any options on printer drivers, by any chance? This used to be a problem pre-windows, but I have not had to tweak a printer in 15 years ....

One thing have to be said, this is a example I made with a screen capture tool and edit to let see what I mean, this is afcourse not printed by the laserprinter.

when one is mirror I get this mis alignment from the printer making pads drills not fit.

My inkjet however fit perfect, also when mirorred, but is not really suitable for artwork making.

regards

OK.

What's weird is that one possible problem, that the paper is picked somewhat "inclined" instead of perfectly vertical, would cause jagged/skewed lines in all 4 rectangle edges, but you show a small clockwise rotation on horizontal lines, yet not on the vertical ones.

Geometrically it does not make much sense.

The other possibility, that vertical displacement is not linear or not the same in different prints or that paper "slips" (it happened to me ) , would cause the top horizontal line, the bottom one or both to be displaced somewhat ... but parallel.

) , would cause the top horizontal line, the bottom one or both to be displaced somewhat ... but parallel.

Yours are not. ?????

What's weird is that one possible problem, that the paper is picked somewhat "inclined" instead of perfectly vertical, would cause jagged/skewed lines in all 4 rectangle edges, but you show a small clockwise rotation on horizontal lines, yet not on the vertical ones.

Geometrically it does not make much sense.

The other possibility, that vertical displacement is not linear or not the same in different prints or that paper "slips" (it happened to me

Yours are not. ?????

OK.

What's weird is that one possible problem, that the paper is picked somewhat "inclined" instead of perfectly vertical, would cause jagged/skewed lines in all 4 rectangle edges, but you show a small clockwise rotation on horizontal lines, yet not on the vertical ones.

Geometrically it does not make much sense.

The other possibility, that vertical displacement is not linear or not the same in different prints or that paper "slips" (it happened to me) , would cause the top horizontal line, the bottom one or both to be displaced somewhat ... but parallel.

Yours are not. ?????

picture you refere on is not from printer, it is a example made with windows paint to show what I mean.

in extreme sens, see it like the laserprinter drum is not aligned so it prints the vertical line not excact vertical, (yes in english it is difficult to explane) the print in the length of paper is possible oke.

I have done a long time ago adjust the drum unit clamp in that printer by make the holes of screws bigger and tilting the drum until it did match, but these modern printers has not this possibility and I do not now if software can do this.

so for clearness, the picture is a ordinairy paint from a screen catch and so it has the ragged lines, in real it is oke.

regards

kees

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Printing PCB film on a laserprinter.