Looks great Vince, have you coated the decal with anything after applying?

Thanks. Someone suggested spraying clear coat and I think its a good idea because off axis the brush on clear coat shows much more. A complete, even coat on the face would be better.

Thanks for all your suggestions. Much appreciated.

Vince

You can get a great silk-screen kit from Michael's Stores.

+1. Silk screening is easy, and if you use a two part epoxy ink and bake it, the legends will outlive the user.

Came across a video on screen printing metal, glass -- How to Screen Print: Graphic Inks, Sticker Printing, Glass, Metal Signs and More - YouTube -- a bit different from textile as 2 part epoxies or solvent based systems are used.

Sounds interesting.

I cany help thinking that on aluminum, you want to be able to laser print a decal on some kind of sticky label. Then, you put this onto your panel, develop it so all the letting areas are clear - I.e the decal dissolves there. Then you etch it for a period then stain it.

Then you remove the ensign decal (peel it off) and you are done.

Spray with lacquer if needed.

Now. Who can make a product like this.

I cany help thinking that on aluminum, you want to be able to laser print a decal on some kind of sticky label. Then, you put this onto your panel, develop it so all the letting areas are clear - I.e the decal dissolves there. Then you etch it for a period then stain it.

Then you remove the ensign decal (peel it off) and you are done.

Spray with lacquer if needed.

Now. Who can make a product like this.

I tried all, in the long run had to learn screen printing, which is the Pro way.

*ANY* ink on *ANY* substrate, be it metal, paper, rubber, glass, whatever.

Have done it even for single use, go figure.

Here I'm printing one of my Bass amps front panel :

That said, sometimes I cheat and for a single prototype I inkjet print on self adhesive coated "magazine paper" .

Ask at a printing supply house and they'll know what you are talking about.

Comes in, say 3 by 4 ft sheets or whatever a commercial offset printer uses, but you cut it to size.

It's the material used for sticky labels.

You apply it on the panel (be careful to avoid bubbles), and clear coat it with some varnish.

*ANY* ink on *ANY* substrate, be it metal, paper, rubber, glass, whatever.

Have done it even for single use, go figure.

Here I'm printing one of my Bass amps front panel :

An externally hosted image should be here but it was not working when we last tested it.

That said, sometimes I cheat and for a single prototype I inkjet print on self adhesive coated "magazine paper" .

Ask at a printing supply house and they'll know what you are talking about.

Comes in, say 3 by 4 ft sheets or whatever a commercial offset printer uses, but you cut it to size.

It's the material used for sticky labels.

You apply it on the panel (be careful to avoid bubbles), and clear coat it with some varnish.

An externally hosted image should be here but it was not working when we last tested it.

That's the paper I used.

Another place to check out in the U.S. is Front Panel Express: Front Panel Design Software and CAD Conversion Service

We chose to go with real engraving. The only problem is paying for the machine. We found one on eBay for a reasonable price. New Hermes is the grand daddy of engraving machines, but they are usually more desirable so attract more attention from bidders.

There are two basic kinds of engravers: CNC and manual. The manual kind come in two flavors: motorized or diamond stylus. The least expensive is the pantograph diamond stylus type. They produce very nice results but require skill.

http://youtu.be/YOrao5bnWO8

Screen printing with epoxy inks onto aluminum appears to be difficult, messy and prone to errors to me. The learning curve for screen printing is fairly steep for great results.

There are two basic kinds of engravers: CNC and manual. The manual kind come in two flavors: motorized or diamond stylus. The least expensive is the pantograph diamond stylus type. They produce very nice results but require skill.

http://youtu.be/YOrao5bnWO8

Screen printing with epoxy inks onto aluminum appears to be difficult, messy and prone to errors to me. The learning curve for screen printing is fairly steep for great results.

I've done both motorized and diamond engravings. Diamond tip may be a bit feeble for front plates, and it's not only the machine that's expensive, the templates are solid money, too. Then there's always the risk of f*- ups.......

Decals are a cheap alternative, but not very durable.......? I't a long time since I played with decals... That's why I wondered about vinyl foils....

Decals are a cheap alternative, but not very durable.......? I't a long time since I played with decals... That's why I wondered about vinyl foils....

Well, then you can get one of the Chinese CNC engravers and be done with it. That'll be $600 plus a computer with a parallel port.

In the very old days, Gen Rad would use an engraver on their front panels. They painted the panel first, and then scratched away the paint as they engraved. Their gear lasted decades and still looks good. HP also engraved their face plates, but filled the engraving with paint. I assume HP used a motorized engraver.

In the very old days, Gen Rad would use an engraver on their front panels. They painted the panel first, and then scratched away the paint as they engraved. Their gear lasted decades and still looks good. HP also engraved their face plates, but filled the engraving with paint. I assume HP used a motorized engraver.

Well, there is always Dymo if you don't have any money.

http://www.dungeonsanddorkwads.com/wp-content/uploads/2013/12/dymo2.jpg

Then you can pretend you are Mesa Boogie in the early days...

http://www.dungeonsanddorkwads.com/wp-content/uploads/2013/12/dymo2.jpg

Then you can pretend you are Mesa Boogie in the early days...

Well, there is always Dymo if you don't have any money.

http://www.dungeonsanddorkwads.com/wp-content/uploads/2013/12/dymo2.jpg

Then you can pretend you are Mesa Boogie in the early days...

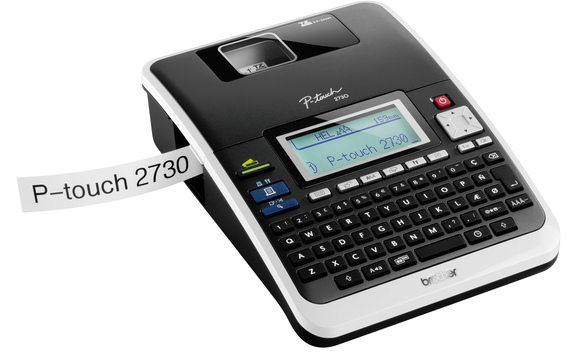

Yeah, or Brother P Touch. Different models available. All colors of stock including clear and font choices. The best of ghetto labeling on the cheap.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Chassis Lettering - What works?