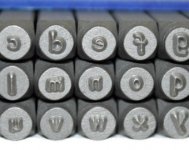

Or these, for that edgy, industrial look....

Can get 2 sizes from Harbor Freight for $9 each.

If you have a coupon you could get another 20% off.

Can get 2 sizes from Harbor Freight for $9 each.

If you have a coupon you could get another 20% off.

Rock On!

gotta love those Chinese!

Offical looking. Nice.

Thanks, there are other fonts available of course, but not as many as on a computer.

Very nice.

For years I toyed with the idea of buying some cheap second hand Pantograph engraver from a failed jewelry shop, or something.

NEVER ever found one.

Then once a jewelry worker told me: you will never get one cheap, because even *if* a jewel shop goes down, some ex-employee gets it as severance pay because it´s a "cash machine", worst case they set it up at home and use it to get some extra money.

No point in selling it.

But now CNC machines are all over the place, and can be used for the same effect.

A friend of mine builds beautiful microphone preamps (think old Neve clones and such) and machines the full enclosures, panels, including lettering, all cutouts, etc. , out of anodized aluminum.

Results are gorgeous and real Pro.

Personally I make small scale production of guitar amps and chose the conventional path: shears, punching and bending machines, silkscreening, to make amp chassis and panels out of raw aluminum sheet.

It all depends (strongly) on how large a batch you make.

For years I toyed with the idea of buying some cheap second hand Pantograph engraver from a failed jewelry shop, or something.

NEVER ever found one.

Then once a jewelry worker told me: you will never get one cheap, because even *if* a jewel shop goes down, some ex-employee gets it as severance pay because it´s a "cash machine", worst case they set it up at home and use it to get some extra money.

No point in selling it.

But now CNC machines are all over the place, and can be used for the same effect.

A friend of mine builds beautiful microphone preamps (think old Neve clones and such) and machines the full enclosures, panels, including lettering, all cutouts, etc. , out of anodized aluminum.

Results are gorgeous and real Pro.

Personally I make small scale production of guitar amps and chose the conventional path: shears, punching and bending machines, silkscreening, to make amp chassis and panels out of raw aluminum sheet.

It all depends (strongly) on how large a batch you make.

Very nice.

For years I toyed with the idea of buying some cheap second hand Pantograph engraver from a failed jewelry shop, or something.

NEVER ever found one.

Then once a jewelry worker told me: you will never get one cheap, because even *if* a jewel shop goes down, some ex-employee gets it as severance pay because it´s a "cash machine", worst case they set it up at home and use it to get some extra money.

No point in selling it.

But now CNC machines are all over the place, and can be used for the same effect.

A friend of mine builds beautiful microphone preamps (think old Neve clones and such) and machines the full enclosures, panels, including lettering, all cutouts, etc. , out of anodized aluminum.

Results are gorgeous and real Pro.

Personally I make small scale production of guitar amps and chose the conventional path: shears, punching and bending machines, silkscreening, to make amp chassis and panels out of raw aluminum sheet.

It all depends (strongly) on how large a batch you make.

Thanks!

Yes, used pantograph machines are expensive! Particularly considering their condition as presented on eBay, for example. If it was made by New Hermes, then the price is even higher. The fonts are expensive as well.

I managed to find a new one by Pepetools for $350. It thought that was a heck of a deal.

I considered getting one of those Chinese CNC routers for $600, but then I'd need a dedicated computer with a parallel port and a lot of other stuff. The old fashioned analog method appeals to me because of it's simplicity and the hand crafted nature of the engraving. I like things that can only be done by hand instead of just pushing a button.

We are moving towards making our own chassis also. I still need more tools and experience to accomplish that.

I think I've seen some of your work here on DIYAudio and it is very good.

if you're handy, you can build a cnc that will easily machine aluminum panels for under $800 (mine was actually right at $600). i did and use it to make all sorts of stuff including cutting and engraving aluminum panels. plate aluminum for a panel is a couple of bucks. Make about a dozen panels and it pays for itself.

if you're handy, you can build a cnc that will easily machine aluminum panels for under $800 (mine was actually right at $600). i did and use it to make all sorts of stuff including cutting and engraving aluminum panels. plate aluminum for a panel is a couple of bucks. Make about a dozen panels and it pays for itself.

Thanks but not that interested. I'd much prefer to have a real milling machine, like this one from Little Machine Shop:

HiTorque Mini Mill, Solid Column with Tooling Package - LittleMachineShop.com

Obviously, I'm not going to use this for engraving. It's just for cutting out rectangular holes in metal, and probably many other things, like maybe custom knobs.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Chassis Lettering - What works?