My heatsinksusa pieces are here, and before using them I wanted to deburr the fin edges and clean them up.

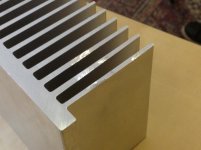

My biggest question I have yet to find an answer for is how do I clean up the cut edges of extruded heatsink. There are some grinding marks and swirls. Would I use a brushing or lapping technique to sand them smooth? Here is a photo showing the swirls and one of the ground spots.

My biggest question I have yet to find an answer for is how do I clean up the cut edges of extruded heatsink. There are some grinding marks and swirls. Would I use a brushing or lapping technique to sand them smooth? Here is a photo showing the swirls and one of the ground spots.

Attachments

Last edited:

For what you show in the image, the saw seems to have gouged a bit, I'd first inquire back to the supplier. Assuming they say that nothing is wrong, I'd try the following idea.

On a known flat surface, like a piece of glass (thick plate glass) or on another flat surface I'd stick on a full sheet of ALO and then rub the entire heatsink across that big flat surface.

WORK WET.

Water or oil.

Best to use "wet or dry" paper. Water on the back side of the paper may give enough adhesion, but if not glue stick, rubber cement, or the stuff they sell to put abrasive shapes to vibrational sanders will work. (non-permanent goop) Thin double stick tape might be ok, but even that few thousandths of an inch will make the surface non-flat. But you could use two strips on along parallel edges and run the work between them, on the flat.

Start with a fairly coarse grit and work back to a fine grit.

If you are going to get them anodized, the anodize process will etch all of the thin fine edges on the fins, where they were cut or sanded.

I'd not use a file, since it is difficult to control and usually results in an uneven result.

If ur not going to have the pieces anodized, then I'd suggest an bath in lye for a while. This will impart a uniform finish on the piece. Try with some scrap to see the results.

EYE PROTECTION AND GLOVES ARE MANDATORY WHEN USING LYE OR ACIDS

Some Alkaline "degreasers" and "cleaners" will act as "brighteners" after a bath in the the lye. They also work to clean the work after using tapping/cutting fluids and filing/sanding.

On a known flat surface, like a piece of glass (thick plate glass) or on another flat surface I'd stick on a full sheet of ALO and then rub the entire heatsink across that big flat surface.

WORK WET.

Water or oil.

Best to use "wet or dry" paper. Water on the back side of the paper may give enough adhesion, but if not glue stick, rubber cement, or the stuff they sell to put abrasive shapes to vibrational sanders will work. (non-permanent goop) Thin double stick tape might be ok, but even that few thousandths of an inch will make the surface non-flat. But you could use two strips on along parallel edges and run the work between them, on the flat.

Start with a fairly coarse grit and work back to a fine grit.

If you are going to get them anodized, the anodize process will etch all of the thin fine edges on the fins, where they were cut or sanded.

I'd not use a file, since it is difficult to control and usually results in an uneven result.

If ur not going to have the pieces anodized, then I'd suggest an bath in lye for a while. This will impart a uniform finish on the piece. Try with some scrap to see the results.

EYE PROTECTION AND GLOVES ARE MANDATORY WHEN USING LYE OR ACIDS

Some Alkaline "degreasers" and "cleaners" will act as "brighteners" after a bath in the the lye. They also work to clean the work after using tapping/cutting fluids and filing/sanding.

Last edited:

Thanks this is this kind of information I am after. I will work with what you gave me. I got them ages ago and have been sitting, and was part of a group buy. Lesson learned. I just want to get to work on these two for now. I also have another four more in 8 or 10" height (its late) for an F5T, so I may as well practice on this one

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.