Hello everyone!

I'll try to explain my problem clearly.

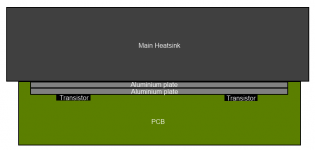

To fix my printed transistors on the heat sink power circuit I need to insert an aluminum plate 6 mm thick but I find only 3 mm plate.

My question is simple:

If I put two plates of thickness 3 minutes between my transistors and the heat sink, it will be effective equivalent to a single sheet of 6 mm.

I made a little drawing.

Regards!

I'll try to explain my problem clearly.

To fix my printed transistors on the heat sink power circuit I need to insert an aluminum plate 6 mm thick but I find only 3 mm plate.

My question is simple:

If I put two plates of thickness 3 minutes between my transistors and the heat sink, it will be effective equivalent to a single sheet of 6 mm.

I made a little drawing.

Regards!

Attachments

Which is preferable anyway to relieve the stress caused by straight legs....you can always bend the trannie legs a bit....

Translation to avoid project16 the inconvenience of using a translator:

Il est préférable de plier les pattes des transistors pour éviter les contraintes causées par un montage droit

imho, you are better off with just a 3mm plate....any reason it had to be 6mm?

with just a 3mm plate you have 1 less thermal junction to worry about...you can always bend the trannie legs a bit....

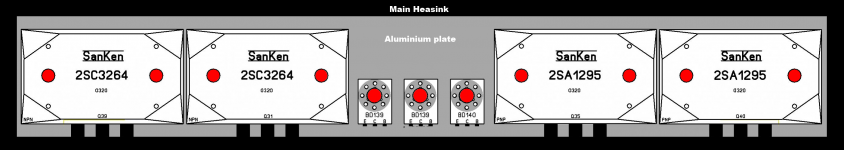

This is to avoid bending the legs of the transistors.

But I can (by bending the legs of Sanken) fix directemment on the main heatsink but I have to add an aluminum thickness for BD139 and 140 because the legs are too short.

Why 6 mm:

Is the distance between the base of one and the edge of Sanken PCB.

Attachments

Which is preferable anyway to relieve the stress caused by straight legs.

Translation to avoid project16 the inconvenience of using a translator:

Il est préférable de plier les pattes des transistors pour éviter les contraintes causées par un montage droit

You can deepen please!

Regards!

This is to avoid bending the legs of the transistors.

But I can (by bending the legs of Sanken) fix directemment on the main heatsink but I have to add an aluminum thickness for BD139 and 140 because the legs are too short.

Why 6 mm:

Is the distance between the base of one and the edge of Sanken PCB.

if you must, small plate spacers for the bd139/140 would be easier to do...

Ok, thank you all and I really do ask the question.

To summarize you have convinced me that it is best to directly heat sink for the power transistors.

I put a spacer under the BD because I do not have a choice or when connected to the plate by the very short thread.

I understood that Elvee meant, he spoke of mechanical stress I think.

Again thank you!

To summarize you have convinced me that it is best to directly heat sink for the power transistors.

I put a spacer under the BD because I do not have a choice or when connected to the plate by the very short thread.

I understood that Elvee meant, he spoke of mechanical stress I think.

Again thank you!

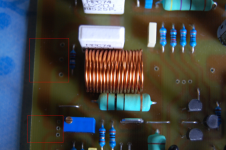

Probably L profile aluminium heat spreader is another option. But it seems there is not too much space on pcb to support the spreader from bottom.

Look at this one:

http://www.diyaudio.com/forums/solid-state/223762-alternative-buffer-topologies-5.html#post3311880

Look at this one:

http://www.diyaudio.com/forums/solid-state/223762-alternative-buffer-topologies-5.html#post3311880

Last edited:

1) sorry but the PCB design is not the best.

It should put transistor pads closer to an edge, so you can attach it easily to the heatsink or an aluminum backpanel

2) if you don't want to redo the PCB, you can (should) mount the transistors straight to the heatsink, and add small wire links so legs reach PCB holes.

3) si vous avez quelques problèmes, vous pouvez écrire en Français, mais même ça, postez la traduction Anglaise.

It should put transistor pads closer to an edge, so you can attach it easily to the heatsink or an aluminum backpanel

2) if you don't want to redo the PCB, you can (should) mount the transistors straight to the heatsink, and add small wire links so legs reach PCB holes.

3) si vous avez quelques problèmes, vous pouvez écrire en Français, mais même ça, postez la traduction Anglaise.

if you don't want to redo the PCB, you can (should) mount the transistors straight to the heatsink, and add small wire links so legs reach PCB holes.

Yes, this is the solution which I think is the best!

Thank you all!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Fixing transistor on heatsink