I guess I'm lucky

Compressed (#20) birch biscuits have not deformed any surfaces yet.

The 1" material weighs 63 lbs/cubic foot. Comparing this to the .75" I used to make a small car enclosure a couple of years ago (for a JL Audio 6W3v2) is not fair. The .75" came from Lowes in the US and is like cardboard by comparison.

Wouldn't the high absorption of the dense MDF have an effect on the "shell" of glue around the biscuit mentioned here?

I would never argue against others' experience but the benefits of the ease of alignment with plate joiners is hard to argue against if appropriate materials are used.

Compressed (#20) birch biscuits have not deformed any surfaces yet.

The 1" material weighs 63 lbs/cubic foot. Comparing this to the .75" I used to make a small car enclosure a couple of years ago (for a JL Audio 6W3v2) is not fair. The .75" came from Lowes in the US and is like cardboard by comparison.

Wouldn't the high absorption of the dense MDF have an effect on the "shell" of glue around the biscuit mentioned here?

I would never argue against others' experience but the benefits of the ease of alignment with plate joiners is hard to argue against if appropriate materials are used.

Made anything lately Cal ?

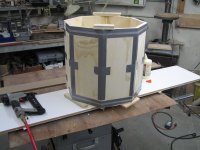

Another trick for when the box is not square is to use the tape and roll method and add the cleats later. Ripping down 2X4's to get a snug fit is a bit of a job though. The top and bottom pieces are just for a bit more gluing surface for the front and back so I wasn't worried about them too much.

Here is the build thread for more pics on how it's done.

http://www.diyaudio.com/forums/multi-way/178459-flying-v-cal-style.html

Tape clamping

Yeah my biskitter gathers dust while I seek out better tape for pulling bits of wood together till the glue goes off. Dont have a micro pinner yet. Believe me I wanted the plate joiner to be the final solution but now...domino? I suspect the beech is the problem. Maybe one of us might try BB biskits sanded to thickness? Anyone? I'm busy.

Yeah my biskitter gathers dust while I seek out better tape for pulling bits of wood together till the glue goes off. Dont have a micro pinner yet. Believe me I wanted the plate joiner to be the final solution but now...domino? I suspect the beech is the problem. Maybe one of us might try BB biskits sanded to thickness? Anyone? I'm busy.

Here's my take on the telegraphing biscuits....You glue up the biscuit and the area is swollen because of the moisture in the glue. You don't wait long enough for the glue to really dry before putting the part through the timesaver or before hand sanding the area. Later when everything settles down you have a hollow where the biscuit is. I have only seen this in solid wood not plywood. It's not a problem if you wait a day for the glue to dry.

Here's my take on the telegraphing biscuits....You glue up the biscuit and the area is swollen because of the moisture in the glue. You don't wait long enough for the glue to really dry before putting the part through the timesaver or before hand sanding the area. Later when everything settles down you have a hollow where the biscuit is. I have only seen this in solid wood not plywood. It's not a problem if you wait a day for the glue to dry.

Biscuits are compressed and designed to expand from the moisture in glue.

I've used them twice. The first was reDiscovery towers and the second was ZRT 2.5 (65 liters.)

The 1" stuff from the cabinet maker is dense (based-on my stuff scale.)

P

Try this: Use tape 90* across the joint. Offset the mitre point about an 1/8" or so past each other while taping the face every 3-4" or so. Flip it over and apply the glue ... fold the joint together and the tape will pull it into alignment. The offset works to apply additional pressure that you'd never be able to achieve taping after the joint has been glued ... (excluding clamps).Another trick for when the box is not square is to use the tape and roll method and add the cleats later. Ripping down 2X4's to get a snug fit is a bit of a job though. The top and bottom pieces are just for a bit more gluing surface for the front and back so I wasn't worried about them too much.

Here is the build thread for more pics on how it's done.

http://www.diyaudio.com/forums/multi-way/178459-flying-v-cal-style.html

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Help With Joints