Hi,

in another tread there was a link to C-cores by Alpha Core. They also sell rectangular phenolic tubes fitting to their cores. But I'm wondering how one manages winding the second etc. layer without seeing the magnet wire falling off the edges? What's the secret?

Best regards!

in another tread there was a link to C-cores by Alpha Core. They also sell rectangular phenolic tubes fitting to their cores. But I'm wondering how one manages winding the second etc. layer without seeing the magnet wire falling off the edges? What's the secret?

Best regards!

there is a step by step picture of winding a transformer in here:

Practical Transformer Winding

although the example was a huge 10kVA transformer.

Practical Transformer Winding

although the example was a huge 10kVA transformer.

Hi,

in another tread there was a link to C-cores by Alpha Core. They also sell rectangular phenolic tubes fitting to their cores. But I'm wondering how one manages winding the second etc. layer without seeing the magnet wire falling off the edges? What's the secret?

Best regards!

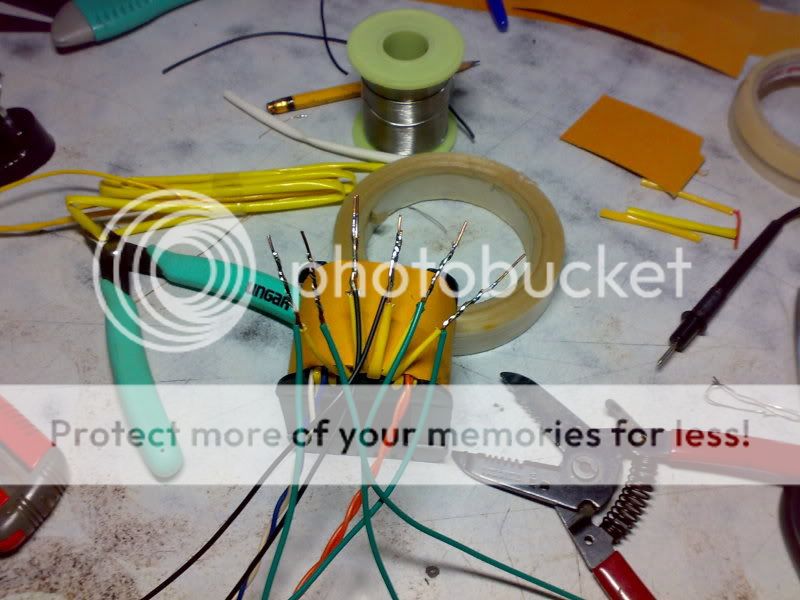

no secret, just give some clearance to the edge say 2mm at least......using a thins sheet of fish paper or Mylar for inter-layer insulation....

Temporary flanges protected with wax paper, so you can slop on some varnish as you wind it up to hold everything nice and vibration free. My method, others may have different views.

there is a step by step picture of winding a transformer in here:

Practical Transformer Winding

although the example was a huge 10kVA transformer.

As the previous user of a three phase 10kVA UPS, huge doesn't come close. The word is also DENSE and heavy as hell. <Then you add the batteries.>

p

Very good looking, Tony!

But how did you avoid the wire's falling off the edges? Did you increase the clearance from layer to layer? And how did you fix the terminal endings?

Best regards!

But how did you avoid the wire's falling off the edges? Did you increase the clearance from layer to layer? And how did you fix the terminal endings?

Best regards!

Very good looking, Tony!

But how did you avoid the wire's falling off the edges? Did you increase the clearance from layer to layer? And how did you fix the terminal endings?

Best regards!

i try to get he same winding width from layer to layer, the ends are fixed with tapes, for smaller gauge wires, this is not hard to do and tape is sensually not needed.....

please look here: http://www.diyaudio.com/forums/power-supplies/191730-my-latest-traffo-build.html

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Winding transformers using a flangeless bobbin