My understanding is that a flat sheet of material gets stiffer by the cube, and that for a speaker, the stiffer the sides the better.

I have a 15mm BB kit coming.

However, doing a simply calculation, 18mm would be about a whopping 75% stiffer.

Questions: If I wanted a stiffer cabinet but the kit can come only in 15mm for a floor standing speaker, would it makes sense to purchase another sheet of 1/8 or 1/4" thick Baltic Birch and glue it on the outside to make the body thicker and stronger? 15mm sounds awfully thin to me but then I'm used to seeing mdf type cabinet.

What do you guys think?

This will be my first build and using a flat pack.

Thanks,

UL

I have a 15mm BB kit coming.

However, doing a simply calculation, 18mm would be about a whopping 75% stiffer.

Questions: If I wanted a stiffer cabinet but the kit can come only in 15mm for a floor standing speaker, would it makes sense to purchase another sheet of 1/8 or 1/4" thick Baltic Birch and glue it on the outside to make the body thicker and stronger? 15mm sounds awfully thin to me but then I'm used to seeing mdf type cabinet.

What do you guys think?

This will be my first build and using a flat pack.

Thanks,

UL

15mm BB is on the same order of stiffness as 1" MDF, and much less massive. So to bring the resonant structure of the MDF in line with the BB you'd have to add on the order of 2x as much bracing to the MDF. The MDF would still have much greater energy storage & retransmission.

For the original frugel-horn 12mm was specifies. 15mm for FH3 is just fine. If you really want to take it up a level, i'd suggest adding a layer of plastic laminate. Very stiff for the mass, a dissimilar material, and with an addiitonal glue layer. it becomes the finish. Just doing the sides with natural everything else could have a very nice aesthetic.

dave

For the original frugel-horn 12mm was specifies. 15mm for FH3 is just fine. If you really want to take it up a level, i'd suggest adding a layer of plastic laminate. Very stiff for the mass, a dissimilar material, and with an addiitonal glue layer. it becomes the finish. Just doing the sides with natural everything else could have a very nice aesthetic.

dave

Dave, this post has NOTHING to do with baltic birch or FH3 or Alpair 7 or Helper Woofer or anyone of the many other subjects I've queried on different boards from here to AudioCircle.

Here's my question: HOW in the world do you keep up with so many board, forums and threads. It doesn't seem to matter whatever or wherever I post, you are on it in short order. Is there actually half a dozen people masquerading as 'Dave' or Planet 10? LOL - I'm not kidding but I'm literally shaking with laughter right now at how you seem to be everywhere all at once.

As far as I know, only one Being is omnipresent but you give me that feeling sometimes. Thanks for giving me good laugh in the best sense. It just strikes me as impossible.

Thanks again. I'll look into the plastic laminate. No idea what that is but it WOULD look very very sharp. i can see it in my mind's eye - black plastic on the side.... or perhaps dark grey with a grey Alpair driver would look sharp!

Regardless, thanks Dave.

UL

Here's my question: HOW in the world do you keep up with so many board, forums and threads. It doesn't seem to matter whatever or wherever I post, you are on it in short order. Is there actually half a dozen people masquerading as 'Dave' or Planet 10? LOL - I'm not kidding but I'm literally shaking with laughter right now at how you seem to be everywhere all at once.

As far as I know, only one Being is omnipresent but you give me that feeling sometimes. Thanks for giving me good laugh in the best sense. It just strikes me as impossible.

Thanks again. I'll look into the plastic laminate. No idea what that is but it WOULD look very very sharp. i can see it in my mind's eye - black plastic on the side.... or perhaps dark grey with a grey Alpair driver would look sharp!

Regardless, thanks Dave.

UL

Plastic laminate -- arborite, formica, more -- literally thousands of colours & patterns.

An example: Formica Corporation : Laminate

dave

An example: Formica Corporation : Laminate

dave

My understanding is that a flat sheet of material gets stiffer by the cube, and that for a speaker, the stiffer the sides the better.

To my recollection that's only if the number of plys is the same in both which is usually not the case. Still if I recall correctly, each 3mm jump in plywood thickness with the assumption that 2 extra ply is used will double the stiffness. For example 18mm 13ply is twice as stiff as 15mm 11ply which again is twice as stiff as 12mm 9ply.

Or you can do what I am doing and use two layers of 18 mm BB with Green Glue between them.

Then you could change your name to UltraStiff...

To my recollection that's only if the number of plys is the same in both which is usually not the case. Still if I recall correctly, each 3mm jump in plywood thickness with the assumption that 2 extra ply is used will double the stiffness. For example 18mm 13ply is twice as stiff as 15mm 11ply which again is twice as stiff as 12mm 9ply.

For a given material, the stiffness increases with the cube (3rd power) of the thickness.........for an easy example, take a long 2x4 and place it between two saw horses laying flat, and compare it's stiffness when laying flat to when on edge.....then a 2x6, 2x8, etc.

Your "rules of thumb" are quite close; 18mm cubed is 5832, and 15mm cubed is 3375, and 12mm cubed is 1728. So 5832/3375=1.72 and 3375/1728=1.95 (not quite 2X for either of these, but 1.95 is close). Taking 5832/1728=3.37, so not quite 4X from thinnest to thickest.

UL - there are a number of reasons why we settled on the combination of 15 & 18mm BB for the FH flat-paks, including the quite signification factor of shipping cost. The approx 20% additional weight isn't the biggest issue, but the combined dimensions of securely wrapped parts would exceed Canada Post's length / girth limits per package.

For those folks building their own from FH plan-set, I can't think of any downside to using 18mm material for the entire enclosure, except for yield. Be aware that with the last couple of revisions to dimensions, there's lots to spare on a 4x8ft sheet, but I was not able to get all parts from a single 5x5 sheet, and the optimization works out quite differently on a batch run of 15 pairs compared to a single.

For those folks building their own from FH plan-set, I can't think of any downside to using 18mm material for the entire enclosure, except for yield. Be aware that with the last couple of revisions to dimensions, there's lots to spare on a 4x8ft sheet, but I was not able to get all parts from a single 5x5 sheet, and the optimization works out quite differently on a batch run of 15 pairs compared to a single.

Audio wise, would there be a practical/noticeable advantage with 18mm over 15mm? That's really the crux of my query.

Thanks,

UL

There is no way to really know without building both versions in the exact same way and take comprehensive measurements.

There are so many other factors to the equation that it becomes like predicting weather.

Since the quantitative approach is not very practical for the DIY one tends to err on the side of caution and over-engineer things (or at least have an open path to upgrade or correct problems if they arise).

If it were me, I would probably lean toward thicker material so that I can eliminate or reduce one more variable in a system that has so many to begin with.

For a given material, the stiffness increases with the cube (3rd power) of the thickness.........for an easy example, take a long 2x4 and place it between two saw horses laying flat, and compare it's stiffness when laying flat to when on edge.....then a 2x6, 2x8, etc.

Your "rules of thumb" are quite close; 18mm cubed is 5832, and 15mm cubed is 3375, and 12mm cubed is 1728. So 5832/3375=1.72 and 3375/1728=1.95 (not quite 2X for either of these, but 1.95 is close). Taking 5832/1728=3.37, so not quite 4X from thinnest to thickest.

I think the roughly doubling holds as the base stiffness per mm is not identical for 18mm/13ply, 15mmm/11ply, and 12mm/9ply.

Btw, if optimum stiff is the most vital aspect which it often is, then consider filmed baltic birch (or really epoxy glued and coated) it has far the greatest base stiffness any non-exotic wood product I know off. It's in many cases also cheaper because the outer coating means that there are no visually aesthetic requirements for this product. The only requirement is maximum stiffness per mm.

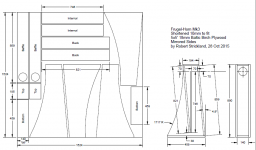

Frugel-Horn Mk3 18mm Baltic Birch 5'x5'

I am planning my FH3 build. I found that by making the FH3 shorter by 10mm, I can fit all of the pieces on one 5x5' sheet of 18mm Baltic birch. Here is my cut plan with revised dimensions:

See attached PDF. I mirror-imaged the sides so the outside of every piece is on the same side of the sheet. The same layout works for the 15mm FH3.

Questions:

Does Baltic birch typically have a better side?

To shorten it, I reduced the back, internal, and front baffle by 10mm. I preserved the 38 mm gap at the bottom and the 70mm gaps at the top. My hunch is that shortening the length of the inner chambers by 1.3% will not change the response significantly. How risky is this?

I am planning my FH3 build. I found that by making the FH3 shorter by 10mm, I can fit all of the pieces on one 5x5' sheet of 18mm Baltic birch. Here is my cut plan with revised dimensions:

See attached PDF. I mirror-imaged the sides so the outside of every piece is on the same side of the sheet. The same layout works for the 15mm FH3.

Questions:

Does Baltic birch typically have a better side?

To shorten it, I reduced the back, internal, and front baffle by 10mm. I preserved the 38 mm gap at the bottom and the 70mm gaps at the top. My hunch is that shortening the length of the inner chambers by 1.3% will not change the response significantly. How risky is this?

Attachments

I think the roughly doubling holds as the base stiffness per mm is not identical for 18mm/13ply, 15mmm/11ply, and 12mm/9ply.

Right on, using MOE specs, there's not quite a 2x increase from 15 - 18 mm BB ply, but only a ~1.4x increase from 18 - 25 mm [only specs I have ATM], so appears to be ~ an exponential ratio.

GM

Audio wise, would there be a practical/noticeable advantage with 18mm over 15mm? That's really the crux of my query.

Thanks,

UL

Depends on the size, shape of the cab, but historically, as long as any one dimension doesn't exceed 12", then 5/8" thick no void plywood is sufficient [BB, appleply, some marine grades]. This was before high power handling woofers were available though, so a good plan to either add bracing or thicker panels for these.

That said, a speaker can't be too massive though, juat a point of diminishing returns, which increases rigidity, so lighter speakers [< ~60 lbs] IME typically benefit from mass loading in the form of heavy weight placed/secured on top such as marble, slate, tempered glass, concrete or similar to better couple them to the floor. A buddy uses large tins filled with hundreds of $$ worth of spare change [total] perched on top of his small 'FR' driver MLTLs, while others have stacked their old vinyl/barbell weights/whatever and I typically have used, recommended, large flower/whatever planters, statues or similar, which I presume helped keep me and those I built for from suffering the dreaded WAF/SAF/SO affliction.

The short answer is if these are the little Fonken style bookshelf speakers, then I seriously doubt the extra stiffness, mass of 18 Vs 15 mm construction would be audible since they're already so rigid, but start stacking weights on it to find what it takes to make an audible difference to its 'tone' to decide if it's a worthwhile/viable tweak.

GM

I build FH3s from time to time - including all the Planet10 flatpaks, and would suggest that you contact Dave regarding performance impact of reducing any of the dimensions by as much as 10mm.

As many of these kits are sold for Alpair drivers that have very thick mounting flange, and require rebating for flush mounting, we use 18mm for the driver baffle. Structurally 15 has proven to work fine for the main carcass, but the thicker material for baffle provides the margin required on the Mark Audio drivers, and any other brands with thicker cast frames - such as TangBands, etc - as opposed to Fostex's FE and FF series with thin stamped frames that can be surface mounted with no negative effect.

The "typical" BB 5x5 sheets I've been using for over a decade now is classified as "C" face / shop grade core , and rather a dice roll in terms of quality of face veneers - I've had some that are gorgeous, and others filled with patched larger knots and minor pinholes not requiring patching or filling to meet that standard.

Also note that many suppliers may also offer 4x8 ft sheets of "Baltic Birch" by any number of brand or local trade names. The breakout for the FH3 on a 4x8 is much more flexible, and allows for running grain pattern on all pieces in the long direction - just a personal foible of mine, perhaps. In fact, due to deteriorated quality of face veneers on the Russian Baltic Birch 5x5s from our local suppliers over the past 5yrs, I've switched to a "domestic*" 4x8 product by Murphy Plywood of Oregon.

Final note is that if your layout is for CNC cutting, allow for sufficient tool bit clearance between all parts, and that not all machine beds will accommodate 1524x1524mm

*"domestic" - interesting story is that 2 separate wholesale sheet goods suppliers advise that these products are actually based on a "platform core" sourced from Europe, with final finish sanding and application of face veneers in NA.

As many of these kits are sold for Alpair drivers that have very thick mounting flange, and require rebating for flush mounting, we use 18mm for the driver baffle. Structurally 15 has proven to work fine for the main carcass, but the thicker material for baffle provides the margin required on the Mark Audio drivers, and any other brands with thicker cast frames - such as TangBands, etc - as opposed to Fostex's FE and FF series with thin stamped frames that can be surface mounted with no negative effect.

The "typical" BB 5x5 sheets I've been using for over a decade now is classified as "C" face / shop grade core , and rather a dice roll in terms of quality of face veneers - I've had some that are gorgeous, and others filled with patched larger knots and minor pinholes not requiring patching or filling to meet that standard.

Also note that many suppliers may also offer 4x8 ft sheets of "Baltic Birch" by any number of brand or local trade names. The breakout for the FH3 on a 4x8 is much more flexible, and allows for running grain pattern on all pieces in the long direction - just a personal foible of mine, perhaps. In fact, due to deteriorated quality of face veneers on the Russian Baltic Birch 5x5s from our local suppliers over the past 5yrs, I've switched to a "domestic*" 4x8 product by Murphy Plywood of Oregon.

Final note is that if your layout is for CNC cutting, allow for sufficient tool bit clearance between all parts, and that not all machine beds will accommodate 1524x1524mm

*"domestic" - interesting story is that 2 separate wholesale sheet goods suppliers advise that these products are actually based on a "platform core" sourced from Europe, with final finish sanding and application of face veneers in NA.

Last edited:

Does Baltic birch typically have a better side?

Apparently it depends on whether it's sanded or not. In my locale, sanded has a better side and un-sanded is 'six of one, half dozen of another', so depends on which grain pattern you prefer.

FWIW, I've used whichever side looked best overall to me and did whatever was required to make it look good and since this includes sanding........... I bought the cheaper un-sanded sheets, though orbital and/or long hand block sanding is typically required; so if you're in a hurry and/or have no suitable dust collection and/or ventilated area for such endeavors, then you're stuck picking through the sanded piles to find a pleasing grain pattern, which around here is precious few since it's not very popular.

GM

No, I won't be using CNC.Final note is that if your layout is for CNC cutting, allow for sufficient tool bit clearance between all parts, and that not all machine beds will accommodate 1524x1524mm

Good information! My Alpair 7.3 drivers just arrived! I have seen the rebate detail on the Madison enclosure plans.As many of these kits are sold for Alpair drivers that have very thick mounting flange, and require rebating for flush mounting, we use 18mm for the driver baffle. Structurally 15 has proven to work fine for the main carcass, but the thicker material for baffle provides the margin required on the Mark Audio drivers, and any other brands with thicker cast frames - such as TangBands, etc - as opposed to Fostex's FE and FF series with thin stamped frames that can be surface mounted with no negative effect.

Thanks to all for the detailed info about Baltic birch!

I have decided that reducing the height 10mm is to risky. I reworked the layout and found that I can just squeeze in canonical FH3 plan if I A) splice one of the bottoms near the baffle or B) change the overlap making the backs 18mm longer and the tops 18mm shorter. PM me if you want either of these layouts.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- 18mm Baltic Birch vs 15mm Baltic Birch for speakers - stiffness