Firstly, a bit of background.

I have worked (both professionally and as a hobbyist) with electronics for 30 years or so.

I'm having a problem with what I think is lead free solder, and tinning of the bit.

My temperature controlled iron is set to between 240 and 270 deg C.

But I cannot get the tip to 'tin' properly - no matter what I try.

I did have some mild success tinning it with some 'Resin Core Solder Wire' that I purchased some years back. I don't have any chemical info on this solder - all it says on the reel is "with resin flux core".

The solder I'm currently using is made by 'Shenmao' and is a 'lead free' solder composed of 99.3% 'Sn' and 0.7% 'Cu'.

I have tried an alternate solder but this has the same chemical composition.

I have attached a picture of the bit I'm currently using (large because I'm working on a PSU for my amp!).

I would be truly grateful if anybody has any suggestions!

I have worked (both professionally and as a hobbyist) with electronics for 30 years or so.

I'm having a problem with what I think is lead free solder, and tinning of the bit.

My temperature controlled iron is set to between 240 and 270 deg C.

But I cannot get the tip to 'tin' properly - no matter what I try.

I did have some mild success tinning it with some 'Resin Core Solder Wire' that I purchased some years back. I don't have any chemical info on this solder - all it says on the reel is "with resin flux core".

The solder I'm currently using is made by 'Shenmao' and is a 'lead free' solder composed of 99.3% 'Sn' and 0.7% 'Cu'.

I have tried an alternate solder but this has the same chemical composition.

I have attached a picture of the bit I'm currently using (large because I'm working on a PSU for my amp!).

I would be truly grateful if anybody has any suggestions!

Attachments

Is there a reason you need that particular solder? Try as a test, going to the local suplier and pick up some clasic 50/50 tin lead stuff and just see if it helps. Its one or the other, temp, or solder composition.

What changed? What is different from the good results that you are used to?

What changed? What is different from the good results that you are used to?

It looks like the tip is really dry (as in no solder on it). I would try some tip tinner. If that doesn't work, "paint" the tip with flux using a flux pen or liquid flux. Do this when the tip is cold. Then turn the iron on and hold a piece of solder to it as it warms up. If that doesn't do the trick, I'm afraid the tip is dead.

~Tom

~Tom

The only things that have changed most recently are the tips.

Tinning the bit has always been problematic though, and I've often had to resort to a bit of gentle treatment with sandpaper.

The tips always seem to go gray / black.

I don't leave the iron on for prolonged periods so it's not that.

I have a moist sponge and keep the tip (once successfully tinned!) as clean as possible whilst working.

One thing I did wonder about, is that I have been working on a lot of older kit, probably assembled with the older lead solder. I did wonder if mixing the types is causing some kind of contamination?

Tinning the bit has always been problematic though, and I've often had to resort to a bit of gentle treatment with sandpaper.

The tips always seem to go gray / black.

I don't leave the iron on for prolonged periods so it's not that.

I have a moist sponge and keep the tip (once successfully tinned!) as clean as possible whilst working.

One thing I did wonder about, is that I have been working on a lot of older kit, probably assembled with the older lead solder. I did wonder if mixing the types is causing some kind of contamination?

Your temperature is too low, set it to 270.

The solder you have purchased is unsuitable for electronics work, it appears to be silver solder for jewellery work and probably does not contain flux.

Purchase some electronics solder, Maplin sell lead free if you are stuck, but I use leaded solder.

The solder you have purchased is unsuitable for electronics work, it appears to be silver solder for jewellery work and probably does not contain flux.

Purchase some electronics solder, Maplin sell lead free if you are stuck, but I use leaded solder.

This was purchased from Maplin!

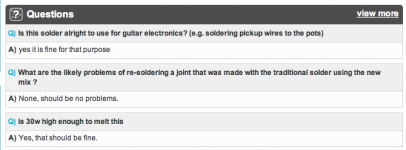

Here is a link to the very product!

If the link doesn't work, search for code N31AR

Interesting to note in the Q&A that it appears to be suitable for electronics?

Here is a link to the very product!

If the link doesn't work, search for code N31AR

Interesting to note in the Q&A that it appears to be suitable for electronics?

Attachments

In spite of all the advertized glories of lead free solder it doesn't wet Nearly as well as the crappiest tin/lead wire and it erodes copper tips the instant a break in the iron clad appears.

You can use zinc chloride based tinning compound, the kind used for pipe soldering, to help out with a badly oxidized tip. Also some steel wool, although horribly messy, cleans a "rusted" tip very aggresively without chewing through the iron clad in one spot as fast as fine sandpaper can.

If you're only doing work for yourself and not jobs where lead free solder is specified you may want to leave your iron on for prolonged periods of time or put away tinned with lead solder.

A 16P nail stands up to lead free solder like no copper clad tip can. I use one in a 25 watt unregulated iron and its poor thermal conductivity limits it's use to surface mount parts, but the tip still looks pretty much the same after 10 years.

Once in a while I'll solder with tin/lead under the kitchen vent hood. In good weather I go outside. The flux in the lead free solders makes me sick anyway.

Also, once in a while you might notice that if you wet the sponge too much it starts working against you.

You can use zinc chloride based tinning compound, the kind used for pipe soldering, to help out with a badly oxidized tip. Also some steel wool, although horribly messy, cleans a "rusted" tip very aggresively without chewing through the iron clad in one spot as fast as fine sandpaper can.

If you're only doing work for yourself and not jobs where lead free solder is specified you may want to leave your iron on for prolonged periods of time or put away tinned with lead solder.

A 16P nail stands up to lead free solder like no copper clad tip can. I use one in a 25 watt unregulated iron and its poor thermal conductivity limits it's use to surface mount parts, but the tip still looks pretty much the same after 10 years.

Once in a while I'll solder with tin/lead under the kitchen vent hood. In good weather I go outside. The flux in the lead free solders makes me sick anyway.

Also, once in a while you might notice that if you wet the sponge too much it starts working against you.

Last edited:

Well, I'm embarrassed to say...

It looks as though my trusty solder station has a fault. Perhaps a break in the cable to the iron, I'm not sure yet until I dismantle and test.

On and off, it was working (sort of) this evening, at one point (no pun intended) I actually had a nice shiny tip!

So it looks as though it's not getting hot enough. (obviously I don't do enough soldering any more to simply hold it under my nose and think 'yeah that's hot enough')..

Thanks for all the input guys, I'll report back with my findings in the next day or so. Of course I may find myself in the position of needing a soldering iron to repair my soldering iron lol.

It looks as though my trusty solder station has a fault. Perhaps a break in the cable to the iron, I'm not sure yet until I dismantle and test.

On and off, it was working (sort of) this evening, at one point (no pun intended) I actually had a nice shiny tip!

So it looks as though it's not getting hot enough. (obviously I don't do enough soldering any more to simply hold it under my nose and think 'yeah that's hot enough')..

Thanks for all the input guys, I'll report back with my findings in the next day or so. Of course I may find myself in the position of needing a soldering iron to repair my soldering iron lol.

And here lies the problem.

Well gentlemen, I have found the problem.

Maplin kindly issue the following instructions:

"Please note: If your item has been purchased prior to 2008 the order code for your spare tip would be order code N71AP"

And yes, those were the bits I ordered.

However, they are the wrong bits for my iron!

Mine takes the longer bit - "N71AP" are the shorter bits! No wonder it doesn't work properly - I don't know how I missed this when changing them over.

Must be old age lol. I did reach my half century earlier this month

Well gentlemen, I have found the problem.

Maplin kindly issue the following instructions:

"Please note: If your item has been purchased prior to 2008 the order code for your spare tip would be order code N71AP"

And yes, those were the bits I ordered.

However, they are the wrong bits for my iron!

Mine takes the longer bit - "N71AP" are the shorter bits! No wonder it doesn't work properly - I don't know how I missed this when changing them over.

Must be old age lol. I did reach my half century earlier this month

Attachments

Well gentlemen, I have found the problem.

Maplin kindly issue the following instructions:

I have bought 2 soldering stations from Maplin and neither of them had the bits last very long. One soldering station died after a couple of moneths.

Just cheap and nasty I guess.

My current iron is an Antex one which has had no problems.

I bought the cheaper one.

I think they were selling them off for about £20.

Having the iron too hot shortens the life of the tip.

I have had problems in the past with tips and it was iron was too hot or the iron was left on for prolonged periods while not being used, both shorten tip life.

I gave my Weller some assist with a propane torch, never worked again.

Got the ground strap soldered to the shield, but that was the last time.

You know, one of them huge copper bands around a 10lb transformer.

Iron + heat gun = generally safe, have done this many times.

Iron + propane = dead iron, take my word, don't try.

Tip is fine, fried something inside, maybe a thermocouple?

I'm not sure exactly how the temperature was regulated?

Stump dead now...

Last edited:

Firstly, a bit of background.

I have worked (both professionally and as a hobbyist) with electronics for 30 years or so.

I'm having a problem with what I think is lead free solder, and tinning of the bit.

My temperature controlled iron is set to between 240 and 270 deg C.

But I cannot get the tip to 'tin' properly - no matter what I try.

I did have some mild success tinning it with some 'Resin Core Solder Wire' that I purchased some years back. I don't have any chemical info on this solder - all it says on the reel is "with resin flux core".

The solder I'm currently using is made by 'Shenmao' and is a 'lead free' solder composed of 99.3% 'Sn' and 0.7% 'Cu'.

I have tried an alternate solder but this has the same chemical composition.

I have attached a picture of the bit I'm currently using (large because I'm working on a PSU for my amp!).

I would be truly grateful if anybody has any suggestions!

1) Try cleaning with wet sponge. ( soldering one)

2) Clean with a 0.No sand paper. That is the one with most smooth surface.

3) Try using regular tin/lead solder only for tinning, later clean it and tin it with ROHS compliant solder.

Is your bit special and pre-coated when you purchased?

Its recommended to change tip temperature low when we are not using it for a while. you can do that by putting some smart circuit which will lower temperature when you rest the gun in the stand ( long back elektor had published some).

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Soldering iron tip problem, help!