A solution of 12g/l of NaOH is a fairly weak solution. It will sting if you have any small puncture or wound, but is weaker than most washing solutions used. Just use disposable gloves andeye protection, if you feel this is dodgy..

( I don't - most times - as I just lift the boards directly from developer to rinse in tempered, running water. Just don't rush it, or make splashes...)

The silicate stuff may work OK, but I think it's more difficult to source, and a lot more expensive...

( I don't - most times - as I just lift the boards directly from developer to rinse in tempered, running water. Just don't rush it, or make splashes...)

The silicate stuff may work OK, but I think it's more difficult to source, and a lot more expensive...

Anyone got any ideas what I can use to dissolve the toner.

I've tried:

Nail Varnish Remover

Ethyl Alcohol

Nothing is budging it so far ?

I use an aerosol can of Klean-Strip Auto Strip (paint stripper). It comes out of the can as a thick foam and just obliterates the toner; no survivors. It's water soluble and risnes off easily. DO NOT get any of this on your skin unless you like strange icey-hot chemical burn sensations.

I've just bought a litre of 100% pure acetone.

Unfortunately my laser printer has run out of toner so I can't experiment.

I did try home brush cleaner but that didn't work.

Maybe the new toner cartridge and the acetone might work.

The nail varnish remover was 50% acetone+ 50% water but it didn't budge the toner.

Unfortunately my laser printer has run out of toner so I can't experiment.

I did try home brush cleaner but that didn't work.

Maybe the new toner cartridge and the acetone might work.

The nail varnish remover was 50% acetone+ 50% water but it didn't budge the toner.

For those foraying into UV board production.

I've used this method up until the point where I tried laser toner transfer.

It has its advantages but it also has its disadvantages:-

1. Unless you buy an expensive UV exposure enclosure you are into the world of photography and experimentation to get your exposure right.

2. The medium that you print onto must be UV transparent.

3. The print must be completely opaque.

I had problems getting a completely BLACK - SOLID - OPAQUE print using an Inkjet printer and Inkjet transparencies. Every time I tried UV exposure I would get pin pricks through the black areas of print.

A Laser printer does a better job because the toner particles are FUSED together.

Having gone to a Laser Printer why not just print on magazine glossy paper and use toner transfer.

I've used this method up until the point where I tried laser toner transfer.

It has its advantages but it also has its disadvantages:-

1. Unless you buy an expensive UV exposure enclosure you are into the world of photography and experimentation to get your exposure right.

2. The medium that you print onto must be UV transparent.

3. The print must be completely opaque.

I had problems getting a completely BLACK - SOLID - OPAQUE print using an Inkjet printer and Inkjet transparencies. Every time I tried UV exposure I would get pin pricks through the black areas of print.

A Laser printer does a better job because the toner particles are FUSED together.

Having gone to a Laser Printer why not just print on magazine glossy paper and use toner transfer.

Here is a horrible quality video I just made taking toner off with the paint stripper....

View My Video

View My Video

I use sodium silicate all the time (I buy it from Circuit Specialists Positive Developer in the US though). You could also use sodium carbonate (sold in the US as "Washing Soda.) I have used this very successfully on negative resist. I have not had good results with NaOH on either positive or negative resists.

Also a previous comment talked about stacking transparencies to improve contrast ratio. I have done that and it does work, but you are better off using a quality transparency film. I have had excellent success with the Accublack http://www.ikonics.com/pdf/user-guide/chromaline/accuproductUG04.pdf which has a high DMAX and low DMIN. Just printing on this film at the highest resolution setting on my printer an (an Epson dye ink printer) yields transparencies that allow me to get get excellent results.

Terry

Also a previous comment talked about stacking transparencies to improve contrast ratio. I have done that and it does work, but you are better off using a quality transparency film. I have had excellent success with the Accublack http://www.ikonics.com/pdf/user-guide/chromaline/accuproductUG04.pdf which has a high DMAX and low DMIN. Just printing on this film at the highest resolution setting on my printer an (an Epson dye ink printer) yields transparencies that allow me to get get excellent results.

Terry

Proper printouts is one of the major quality factors in PCB making. If using regular transparencies, do use quality products. The slightly matte versions gives better results.

For laser prints we use product called LaserStar, available from MegaUK among others.

This gives excellent contrast and black-fill in larger areas like ground planes, as well as fine lines. A bit pricey, though....

For some strange reason, it looks and feels a lot like the polyester drafting film we used in the 70s.........

For laser prints we use product called LaserStar, available from MegaUK among others.

This gives excellent contrast and black-fill in larger areas like ground planes, as well as fine lines. A bit pricey, though....

For some strange reason, it looks and feels a lot like the polyester drafting film we used in the 70s.........

I've just bought a litre of 100% pure acetone.

Unfortunately my laser printer has run out of toner so I can't experiment.

I did try home brush cleaner but that didn't work.

Maybe the new toner cartridge and the acetone might work.

The nail varnish remover was 50% acetone+ 50% water but it didn't budge the toner.

The 100% PURE Acetone did the trick.

50-50 Nail Varnish remover just doesn't work.

Hi Pete,

Okay, we're both over the hill then.

I bought an IBM 5150 for my shop (no HDs, then the horrid Seagate ST-225 dead things). I also had to buy the $5K luggable, no HD in that either. Dos 2.0, then upgraded to DOS 2.1. Remember DOS 3.0? It had a habit of linking a sub-directory to the root. Instant "sorry about your data" situation.

I even had a Tallgrass 20 MB external drive that used a driver card inside the PC. The entire setup was noisy, but who would ever need more than 256 Kb? Yeah, right! You know, I still use IBM DOS 7.0 for some tasks. It's solid, it works and it only does precisely what you tell it to do - when you tell it to do it. There is value in that.

Back to making boards. So far, only the blue paper works for me. Back in time when I used UV lamps, the positive method worked about the best. A couple clues for the best boards: Keep the sensitized PCB cool with muffin fans during exposure. A number two (2) photo flood works really well for exposure. Keep it close to 12" above your artwork, and use a contact fixture or a really clean sheet of glass. The glass must be without lead or anything else that might block the UV light. Using sunlight was never successful as reported by some. Once I started doing this, my developer time was unimportant beyond the minimum - no more losing your artwork!

The stuff GC (General Cement) sells is great. Even the positive resist spray works well. You can cut your boards to size and then sensitize them to UV. Note that these boards will be more sensitive to development time. You have to watch carefully, but it's pretty easy once you get the hang of it. I never did find a printed transparency that worked. I used the rub down lines and donuts for my positive artwork.

-Chris

Okay, we're both over the hill then.

I bought an IBM 5150 for my shop (no HDs, then the horrid Seagate ST-225 dead things). I also had to buy the $5K luggable, no HD in that either. Dos 2.0, then upgraded to DOS 2.1. Remember DOS 3.0? It had a habit of linking a sub-directory to the root. Instant "sorry about your data" situation.

I even had a Tallgrass 20 MB external drive that used a driver card inside the PC. The entire setup was noisy, but who would ever need more than 256 Kb? Yeah, right! You know, I still use IBM DOS 7.0 for some tasks. It's solid, it works and it only does precisely what you tell it to do - when you tell it to do it. There is value in that.

Back to making boards. So far, only the blue paper works for me. Back in time when I used UV lamps, the positive method worked about the best. A couple clues for the best boards: Keep the sensitized PCB cool with muffin fans during exposure. A number two (2) photo flood works really well for exposure. Keep it close to 12" above your artwork, and use a contact fixture or a really clean sheet of glass. The glass must be without lead or anything else that might block the UV light. Using sunlight was never successful as reported by some. Once I started doing this, my developer time was unimportant beyond the minimum - no more losing your artwork!

The stuff GC (General Cement) sells is great. Even the positive resist spray works well. You can cut your boards to size and then sensitize them to UV. Note that these boards will be more sensitive to development time. You have to watch carefully, but it's pretty easy once you get the hang of it. I never did find a printed transparency that worked. I used the rub down lines and donuts for my positive artwork.

-Chris

Im assuming you are in Bangalore.

There are no brand names. The retailer re-packages the chems in smaller quantities. But they are still quite expensive. You need: (1) Negative Photo Resist (PR). (2) PR developer (3) Blue dye (4) PR solvent (5) Pumice powder. (6) Ferric Chloride

.

.

.

vkj

Wow, vkj. That's a lot of work.

Thanks for the detailed info. I am in Hyderabad.

I think I'll stick to toner transfer and work on perfecting the technique

Unused UV Light Box

Hello,

I have an Ultra Violet light box that hasn't been used for a long time. The specifications are:-

Model: Decon 415, Type: UVL-415

Exposure area = 470 x 255 mm, 4 off 15 W tubes, total power 60 W.

Overall dimensions = 625 x 290 x 130 mm excluding hinges and catches

Clockwork adjustable timer, 0 to 6 minutes.

A quick, not recommended, glance at the Ultra Violet light shows that it's working.

The foam on the lid has gone all crunchy and is turning to dust.

It's made of chip board so it's heavy and will need to be collected.

It's free to anyone who can make use of it.

Hello,

I have an Ultra Violet light box that hasn't been used for a long time. The specifications are:-

Model: Decon 415, Type: UVL-415

Exposure area = 470 x 255 mm, 4 off 15 W tubes, total power 60 W.

Overall dimensions = 625 x 290 x 130 mm excluding hinges and catches

Clockwork adjustable timer, 0 to 6 minutes.

A quick, not recommended, glance at the Ultra Violet light shows that it's working.

The foam on the lid has gone all crunchy and is turning to dust.

It's made of chip board so it's heavy and will need to be collected.

It's free to anyone who can make use of it.

Attachments

For those foraying into UV board production.

...

3. The print must be completely opaque.

I had problems getting a completely BLACK - SOLID - OPAQUE print using an Inkjet printer and Inkjet transparencies. Every time I tried UV exposure I would get pin pricks through the black areas of print.

A Laser printer does a better job because the toner particles are FUSED together.

Having gone to a Laser Printer why not just print on magazine glossy paper and use toner transfer.

I go to a local printer and have them print my film on an 'Imagesetter'. This is the device they use to make the films for photo process printing plates. The print is absolutely opaque and pin hole free, everytime. If the design is small I have several printed in a letter size film and save these as spares should I damage my working film. They charge me about $10CAD for the pleasure.

I bought an IBM 5150 for my shop (no HDs, then the horrid Seagate ST-225 dead things). I also had to buy the $5K luggable, no HD in that either. Dos 2.0, then upgraded to DOS 2.1. Remember DOS 3.0? It had a habit of linking a sub-directory to the root. Instant "sorry about your data" situation.

-Chris

Geez, you are taking me backkk...My first PC a was a dual floppy Compaq, luggable (sewing machine white case) circa late '82 or early '83.

Then I joined HP, and entered the world of HP computers - HP85 w/ tape drive, HP9836, HP9816, and of course, the real time HP1000's. This was 1984. Microsoft was a tiny blip of a company.

Hard drives of say, 100MB were the size and weight of a small dishwasher.

This was back when floppy disks were single sided or dual sided, and only HP had the cool little 3.5" floppies, again, all single sided to start.

Getting back to PC boards, I played around with many toner transfer products for a long time, and ended up using the Pulsar stuff, with great results. Their toner transfer paper is excellent, but the real key is the very inexpensive TRF foil.

This TRF foil is applied over the toner image once it is on the copper side of the PC board. It is also "ironed on". It bleeds, seals, and fill in gaps on the toner, to make a better image. See the blurb here

PCB "Fab-In-A-Box" ... The 8min circuit board system

I've made a LOT of boards with this stuff, it works. I have no affiliation to them.

Bob

Remember the Fujitsu Eagle drive?

10.5" platters, 600W, 30 seconds to spin up, lol!

Fujitsu Eagle - Wikipedia, the free encyclopedia

http://museum.ipsj.or.jp/computer/device/magnetic_disk/images/0013_02.gif

We used a Xylogics 440 disk controller that was 2 Multibus 1

boards that included a microcoded bit slice processor.

10.5" platters, 600W, 30 seconds to spin up, lol!

Fujitsu Eagle - Wikipedia, the free encyclopedia

http://museum.ipsj.or.jp/computer/device/magnetic_disk/images/0013_02.gif

We used a Xylogics 440 disk controller that was 2 Multibus 1

boards that included a microcoded bit slice processor.

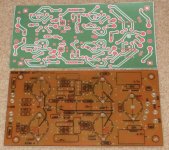

toner transfer PCB

Still at it with the next project, RIAA preamp. Toner transfer method as my previous post. The last pic is after soaking the pcb in cold water to allow the paper to disolve and lift from the melted toner on the copper. All that is left on the top of the toner is a layer of the clay from the paper. If there are any small voids, I use a paint brush with modeling enamel and do a little touch up. The top of the PCB is black toner with the white clay layer removed. If you scrub too hard, you can remove the toner as well.

Also working on a hybrid tube Mosfet headphone amp with boxandall tone section and a couple of power supply pcbs.

I use green stiff floral foam to mock up the pcb to verify component count and lead spacings. When the PCB is etched and drilled, I just transfer the parts to the PCB.

Still at it with the next project, RIAA preamp. Toner transfer method as my previous post. The last pic is after soaking the pcb in cold water to allow the paper to disolve and lift from the melted toner on the copper. All that is left on the top of the toner is a layer of the clay from the paper. If there are any small voids, I use a paint brush with modeling enamel and do a little touch up. The top of the PCB is black toner with the white clay layer removed. If you scrub too hard, you can remove the toner as well.

Also working on a hybrid tube Mosfet headphone amp with boxandall tone section and a couple of power supply pcbs.

I use green stiff floral foam to mock up the pcb to verify component count and lead spacings. When the PCB is etched and drilled, I just transfer the parts to the PCB.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- making pc boards