Thanks CaféNoir,

It looks great and is definitely more to my liking, especially if it is cheaper than the mono enclosures too (two of them, I mean)

It's not my objective to make a cheap chassis. Buy an off the shelve 1U chassis and you're sorted.

It is my objective however to develop a chassis for the DIY community here whereby we offer something which is generally not available to DIY'ers albeight at a reasonable price. There are plenty of companies who produce somthing cheap and chearful, it's just my belief that the ncore deserves something more "appropriate".

Does it make more sense to do a dual monoblock type chassis ? While spending 200 euros on a pair of monoblock chassis might put some off spending 100 euro per channel isn't bad at all. Should be able to get more bang for your chassis buck doing a dual mono ?

P.S. I vote for rack friendly chassis aka no tubular designs

P.S. I vote for rack friendly chassis aka no tubular designs

I'll have a stab at drawing something over the weekend or so. Should get the conversation going....;-)

Good news!

My personal preference is a cube-like case.

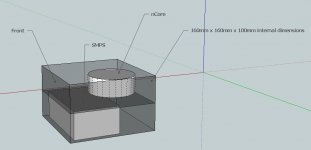

The arrangement I'm considering has PSU at the bottom and the Ncore module on the top (with a panel separating compartments).

I have attached a very rough sketch to give you guys an idea - though dimensions would need to be adjusted a bit (SMPS and NCore module were sketched based on their published dimensions).

IMHO these little cubes would look sexy if they were made hexacube-style and would also have room to spare for aux circuits - but ofc that's just my take!

In general, though, I think a mono-block design would interest more people.

Attachments

Last edited:

Does it make more sense to do a dual monoblock type chassis ? While spending 200 euros on a pair of monoblock chassis might put some off spending 100 euro per channel isn't bad at all. Should be able to get more bang for your chassis buck doing a dual mono ?

P.S. I vote for rack friendly chassis aka no tubular designs

Although a stereo version might be attractive to some people, I would expect the majority of DIY'ers to favour a mono version. Especially when active crossovers and/or multiple channels are involved. A stereo + a mono version would reduce volume and increase tooling cad/cam costs resulting in a higher price.

Should volume be sufficient then obviously the story changes.

With regards to a 2-tier cube style enclosure, this would involve cutting with rather large router bits to go that deep whilst controlling vibrations. This reduces available internal width due to the radii.

I think it's key to maintain clean, elegant and "simple" lines. This ensures production losses are kept at a minimum and we achieve maximum yield. Cutting times (and CAM costs) soon ramp up when working with many compartments, levels, notches etc.

Finish wise I'm think of a process whereby we bead blast, etch and colour anodize. Black or silver.

We could also do a CNC engraving of "nCore".

Inlet is to be decided by us. XLR standard neutrik 24mm presumably. Probably best to do a standard spaced WBT hole for the binding posts so everybody can fit their favourite version.

Preferably just a glasfibre light at the front and a mains swich at the back. Even the expensive "vandal" style switches look out of place in my opinion. A CNC'd button at the front to match the case would add quite a bit to the overall cost.

Just a few thoughts....

Richard

Last edited:

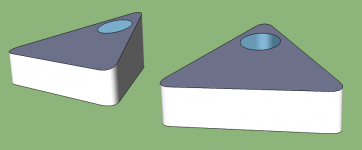

Here is my contribution to the effort for a mono-block nCore amp case.

It is not typical, but neither nCore is

The top of the case is inclined, with a round window centered on top of the module,

in order to be easier to be seen without standing in front of the case.

One disadvantage is the placement of the connectors due to the angle

on the back side, but it is solvable...

It is not typical, but neither nCore is

The top of the case is inclined, with a round window centered on top of the module,

in order to be easier to be seen without standing in front of the case.

One disadvantage is the placement of the connectors due to the angle

on the back side, but it is solvable...

Attachments

Why is a SMPS power supply the prefered choise for the NCore? Isn't there a possibility it sounds better with "conventional" power supply?

Perhaps I have overlooked it, but can someone explain me what input stage has been used for the NCore? Is it op-amp like in the UCD modules?

Perhaps I have overlooked it, but can someone explain me what input stage has been used for the NCore? Is it op-amp like in the UCD modules?

It's not my objective to make a cheap chassis. Buy an off the shelve 1U chassis and you're sorted.

It is my objective however to develop a chassis for the DIY community here whereby we offer something which is generally not available to DIY'ers albeight at a reasonable price. There are plenty of companies who produce somthing cheap and chearful, it's just my belief that the ncore deserves something more "appropriate".

Richard,

I think we are many who highly appreciate that you buy into this thread with your contributions on casing possibilities, so first of all, thank you very much for participating

What I meant with the stereo and "more versatile" enclosure was not primarily to get something cheap. At this point any ncore build would not be cheap in any way, so aiming at cheap mass-market makes no sense of course. My point instead was to make the chassis able to be used in more ways than just 1 smps + 1 ncore. If it will be more generally usable, there will be a bigger potential market both within the ncore user-community and for other DIY audio applications. This would be great as i have the feeling that there is a general lack of high quality chassis´s for DIY´ers and your contribution could be great for more than ncore users and thus also for your business

Personally I don´t get the mono amp fascination, but you may have a better idea of the general bias of the ncore DIY´ers.

Lets hear what people prefer? -mono for 1 smps and 1 ncore, or something wider for up to 4 ncore´s and maybe 2 smps´s. (for biamping or triamping, one smps should actually be enough)

To me the ability to build a 1,2,3,4 channel amp in one case and use the same chassis for pre amp and DAC and phonostage or whatever i may want to build would greatly add to my appreciation of your product.

That said, I vote for the black anodized color as it would look soo good and neat. There has been way too much silver-face finishes during the last decade. Please give us something black and stunning

cheers,

Why is a SMPS power supply the prefered choise for the NCore? Isn't there a possibility it sounds better with "conventional" power supply?

I would really like to know that too...

[/QUOTE] Perhaps I have overlooked it, but can someone explain me what input stage has been used for the NCore? Is it op-amp like in the UCD modules?[/QUOTE]

ncore has a discrete high quality buffer with build in HXR regs, so it should be stunning

cheers,

Last edited:

Hi Richard

I agree with everything you say. Mono cases are the way to go and will very, very likely bring you more volume. And volume is the key to bring down tooling cost per unit.

Rather than a cubic shaped case, I would prefer a flat one. It could then be attached directly to the back of the speakers, if one so desires. However, front width should be 20 cm at most, so that two units positioned side by side in a shelf occupy the same width or less than the 43 cm standard for Hi Fi gear. This should be very easy to achieve. There should be a little bit of spare space left inside for those who would like do add some of their own circuitry or components.

To simplify things, I recommend to use a mains IEC socket which includes both a power switch and a fuse holder. And I like your idea of a clean and simple design with just a fibre light at the front.

I agree with everything you say. Mono cases are the way to go and will very, very likely bring you more volume. And volume is the key to bring down tooling cost per unit.

Rather than a cubic shaped case, I would prefer a flat one. It could then be attached directly to the back of the speakers, if one so desires. However, front width should be 20 cm at most, so that two units positioned side by side in a shelf occupy the same width or less than the 43 cm standard for Hi Fi gear. This should be very easy to achieve. There should be a little bit of spare space left inside for those who would like do add some of their own circuitry or components.

To simplify things, I recommend to use a mains IEC socket which includes both a power switch and a fuse holder. And I like your idea of a clean and simple design with just a fibre light at the front.

Thanks all for your contributions. I'm open to the idea to leave some space for additional circuitry, but wonder at this point what that additional circuitry could add, given the fact that we're talking about a mono power amplifier. Furthermore, you'd have to cater for possibly blank in- or outputs.....thinking about it, we'd then be making a universal case rather than a bespoke case for the ncore. I'd want this to be a ncore enclosure. I've done universal enclosures and there have never been two enclosures which were the same (except for customers ordering multiples). It's not going to work when trying to align thoughts. Lets's stick with a mono design and optional stereo should volume be sufficient.

Inlet is to be decided by us. XLR standard neutrik 24mm presumably. Probably best to do a standard spaced WBT hole for the binding posts so everybody can fit their favourite version.

Fine, but I think you should consider cutouts for three "D-form" neutrik connectors: signal input (XLR or RCA), speakon and powercon.

Particularly for a monoblock, that might be placed behind the speaker on the floor, using those locking speakon and powercon connectors is very nice.

I suspect for economies of scale, both XLR & RCAs would be necessary, as well as standard speaker binding posts and an IEC.

Speakon, powercon and only XLR connectors will greatly diminish the potential market.

And it is only my opinion, but a classic chassis design vs. some sort of cyllindrical design would have much more mass appeal. Everything in our world eventually settles into a standard because it's what most people prefer. Some sort of creative chassis may look cool to some, but if you are designing for the masses (and that's what economies of scale are all about), it may be more successful to stick with a design that is more conventional looking and acceptable to more people.

Speakon, powercon and only XLR connectors will greatly diminish the potential market.

And it is only my opinion, but a classic chassis design vs. some sort of cyllindrical design would have much more mass appeal. Everything in our world eventually settles into a standard because it's what most people prefer. Some sort of creative chassis may look cool to some, but if you are designing for the masses (and that's what economies of scale are all about), it may be more successful to stick with a design that is more conventional looking and acceptable to more people.

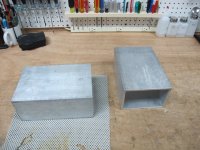

I couldn't find a case that I liked, and wasn't super expensive. So I built one myself out of a 4" x 6" aluminum extrusion. I liked the DIYenclosures cases, but he seems to not be around anymore.

I'm not a big fan of lots of lights, big NASCAR-like logos, so many case designs don't appeal to me. I go for the subtle look.

Sheldon

I'm not a big fan of lots of lights, big NASCAR-like logos, so many case designs don't appeal to me. I go for the subtle look.

Sheldon

Attachments

Neat job stokessed, they look really nice. I´ll imagine that they are rock solid and a perfect mechanical stiff platform for the audio circuitry! THey remind me of the naim chassis which also feature a big rigid aluminum extrusion. They have the electronics mounted on a sledge-like thing which slide into the extrusion.

I like the extrusion idea very much and have considered it myself, but would like to have different dimensions: a lot wider and max 3" tall. Than I haven´t been able to find

I like the extrusion idea very much and have considered it myself, but would like to have different dimensions: a lot wider and max 3" tall. Than I haven´t been able to find

- Status

- Not open for further replies.

- Home

- Amplifiers

- Class D

- Hypex Ncore