Has anyone here tried to cut a gap in a ferrite toroid using one of those diamond-coated circular saws intended for cutting ceramic tiles? It seems as if it would be a good way to make a gapped toroid for the larger sizes (say 50mm diameter and above).

Tried that with 3F3 Toroid core 1.5inch dia & 1.2mm gap, it worked well but the winding over that gap was producing much heat than ungapped area, but its way cheaper than material-2

Tried that with 3F3 Toroid core 1.5inch dia & 1.2mm gap, it worked well but the winding over that gap was producing much heat than ungapped area, but its way cheaper than material-2

As Eva says, it is wise not to continue the winding over the gap.

If you donot cover the gap, it will turn into EMI inferno

Stray field is very freaky

You are quite right about that. Then again, if you wind over the gap the eddy current loss in the wire from the fringing field can be very high. Perhaps the old compromise of multiple parallel thinner insulated wires to minimise the eddy-current loss, together with a winding uniformly distributed around the toroid is stil the best way?

You are quite right about that. Then again, if you wind over the gap the eddy current loss in the wire from the fringing field can be very high. Perhaps the old compromise of multiple parallel thinner insulated wires to minimise the eddy-current loss, together with a winding uniformly distributed around the toroid is stil the best way?

expensive a little bit

If there is no eddy current, then there is no (or not significant) shielding effect, so I'm not going to decrease stray field this way any time. A copper sheet at some distance may be OK.

But I have absolutely no problem with stray field this way either. In front of the gap there are electrolyte caps, behind it there is the heat-sink, under the coil there is a thick ground layer, and the sensitive circuits are on the other side, 8 cm away. The users of this shouldn't listen to AM receivers next to it.

I've made real EMI infernos before, despite of the completely closed magnetic circuit it produced so much EMI under load, that my PC gone mad, the mouse started to go everywhere, and clicking. I noticed it when it stopped the Winamp.

But this is history now, this amp with the gapped ferrite is EMI compatible with everything I've used with.

Magnetic field decreases fast with distance, shielded by almost any metal (at this freq), so I'm not afraid of that.

But I have absolutely no problem with stray field this way either. In front of the gap there are electrolyte caps, behind it there is the heat-sink, under the coil there is a thick ground layer, and the sensitive circuits are on the other side, 8 cm away. The users of this shouldn't listen to AM receivers next to it.

I've made real EMI infernos before, despite of the completely closed magnetic circuit it produced so much EMI under load, that my PC gone mad, the mouse started to go everywhere, and clicking. I noticed it when it stopped the Winamp.

But this is history now, this amp with the gapped ferrite is EMI compatible with everything I've used with.

Magnetic field decreases fast with distance, shielded by almost any metal (at this freq), so I'm not afraid of that.

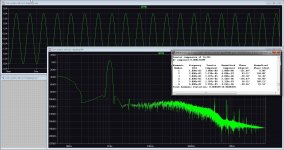

Dual flat spot distortion

This is an interesting concept and supports my listening tests where the lowest tolerable value (I go as low as 3.5uH in my TK2050 amps) for the output inductor yields the best sound quality. Everyone here blamed the change in sonics on the increased peak at 65KHz lifting the frequency response in the audio band but it is only a .5db increase at 20KHz so I knew that there must be another mechanism at work for the improvement. Do you have a link that will explain class D dual flat spot distortion further?One advantage of a low inductance is that it pushes the class d output stage dual flat-spot distortion notches much further to either side of zero so that they only come into play at relatively high levels when absolute distortion doesn't matter as much anyway.

This is an interesting concept and supports my listening tests where the lowest tolerable value (I go as low as 3.5uH in my TK2050 amps) for the output inductor yields the best sound quality. Everyone here blamed the change in sonics on the increased peak at 65KHz lifting the frequency response in the audio band but it is only a .5db increase at 20KHz so I knew that there must be another mechanism at work for the improvement. Do you have a link that will explain class D dual flat spot distortion further?

It's been discussed on this forum before, but you are seeing the curious effect on deadtime of the peak-to-peak current of the output inductor current of a class-d amplifier. As long as the output inductor current ripple is larger than the load current at the moment of switching, its current is in the right direction to force the output stage node voltage to begin slewing to the other rail immediately when both MOSFETs turn off at the beginning of deadtime (this is natural commutation - also known as soft switching). For larger load currents, slewing doesn't commence until the end of deadtime when the other MOSFET forces the voltage to change. Thus, unlike a linear class-b amplifier (where deadtime is at zero output) there are two deadtime zones at non zero load current (symmetrically spaced about zero).

This links to a prior post that shows this effect graphically: http://www.diyaudio.com/forums/class-d/76085-dead-time-crossover-distortion.html#post872569

Hello Mr. analogspiceman,

I have a problem that is not related to this thread but I tryed to contact you over you're email and i did not get any answer.

My problem is that I need the Lt Spice models for 2 IRF transistors.

The transistors are IRFH5020pbf and IRFH5015pbf.

If you could help me in this matter it would be great.

Kind regards,

savu

I have a problem that is not related to this thread but I tryed to contact you over you're email and i did not get any answer.

My problem is that I need the Lt Spice models for 2 IRF transistors.

The transistors are IRFH5020pbf and IRFH5015pbf.

If you could help me in this matter it would be great.

Kind regards,

savu

Coil heating

Back to the original question of coil heating.

I have an identical pair of car audio Class D 1KW Monoblock amplifiers.

irrigardless of load (i.e. even at idle) The coil in one of these amplifiers will get so hot, it will burn you. While the other amplifier doesn't have a problem.

Both amplifiers draw the same idle current from the power source. ~12W

Back to the original question of coil heating.

I have an identical pair of car audio Class D 1KW Monoblock amplifiers.

irrigardless of load (i.e. even at idle) The coil in one of these amplifiers will get so hot, it will burn you. While the other amplifier doesn't have a problem.

Both amplifiers draw the same idle current from the power source. ~12W

Coil Heating

Hi Klausix

I wouldn't worry too much about the coil heating as long as it's less than 60 deg C or so. Most ferrite materials actually have slightly better performance (lower THD) at elevated temperatures, so a little heating is not all bad, unless of course you are very focussed on the power consumption.

The causes of the heating can be many. The proximity effect is one, if you have several layers of windings. Another very likely reason is the skin effect of copper. If you have a slope frequency of 20-30 MHz, even a thick copper wire has a rather high resistance at transitions. This is due to the skin effect, meaning that current only flows in the outer very thin layer of the wire, and not in the whole cross section, at high frequencies. Depending on the slope frequency, the skin effect can heat your coil quite a bit. Winding coils and transformers for that matter, is almost a science in it's own right, and many people experiment with ways to optimize them for their purposes. There are actually forums on the internet dedicated to just coil winding.

But again, don't worry too much about it unless the coil gets very hot.

Hi Klausix

I wouldn't worry too much about the coil heating as long as it's less than 60 deg C or so. Most ferrite materials actually have slightly better performance (lower THD) at elevated temperatures, so a little heating is not all bad, unless of course you are very focussed on the power consumption.

The causes of the heating can be many. The proximity effect is one, if you have several layers of windings. Another very likely reason is the skin effect of copper. If you have a slope frequency of 20-30 MHz, even a thick copper wire has a rather high resistance at transitions. This is due to the skin effect, meaning that current only flows in the outer very thin layer of the wire, and not in the whole cross section, at high frequencies. Depending on the slope frequency, the skin effect can heat your coil quite a bit. Winding coils and transformers for that matter, is almost a science in it's own right, and many people experiment with ways to optimize them for their purposes. There are actually forums on the internet dedicated to just coil winding.

But again, don't worry too much about it unless the coil gets very hot.

Hi guys

How do you like super mss (sendust) toroids from Arnold?

Seems like very good losses/price/dimantions compromise for me.

Sendust Cores with 14 & 26u materials are perfect for Class-D.

Sendust Cores with 14 & 26u materials are perfect for Class-D.

Select AL 80 or less. With proper inductor value vs switching speed.

Some people make mistake dont see the inductor value vs switching speed. Proper inductor selection, inductor value match to switching speed is one the most important key of best sounding amp. For me rule of the thumb, 3 volt peak to peak ripple output during idle will give good result consistency.

- Home

- Amplifiers

- Class D

- Class-D Amp LC-Filter: Coil heating