I might use an apparently novel output inductor type instead of the type 2 red iron powder toroid that is often preferable.

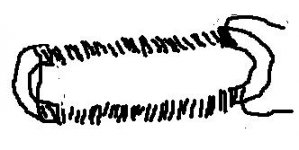

I am considering winding a straight, single layer coil with a diameter equal in size to a small toroid that I have plenty of to spare. Then I plan to use a dremel cutting wheel to slice the toroid in half. I would then bend the coil in half and cap each double end with a half toroid to direct the emitted magnetic field between adjacent coil ends. I would hope this can provide the high saturation level of air core without emitting a big external magnetic field.

Since this approach might have a high Q, it might not be ideal for a class D amplifier. Yet I am still interested in it, maybe at least as an option for SMPS somehow.

I am considering winding a straight, single layer coil with a diameter equal in size to a small toroid that I have plenty of to spare. Then I plan to use a dremel cutting wheel to slice the toroid in half. I would then bend the coil in half and cap each double end with a half toroid to direct the emitted magnetic field between adjacent coil ends. I would hope this can provide the high saturation level of air core without emitting a big external magnetic field.

Since this approach might have a high Q, it might not be ideal for a class D amplifier. Yet I am still interested in it, maybe at least as an option for SMPS somehow.

Do you mean this way? (attached) This has a very low Al value, you needed a very large number of turns, and this leeds to high loss, and yet the stray field wont be low really. You'd better cut the toroids into quarters (or smaller parts), join them back together with 0.3...0.8 mm gaps, and wind it normally. It's good to leave the areas over the gaps free of wires, but not neccessary.

High Q is not a problem for class D audio output filter, but a requirement.

High Q is not a problem for class D audio output filter, but a requirement.

Attachments

Re: Re: Re: Hybrid Output Inductor

In a gapped toroid, the magnetic field bulges externally at each gap. I've noticed that in images of a straight coil, the field remains inside the coil except at the ends.

I wonder why iron powder is preferred to gapped ferrite besides magnetic field containment. Could that be the only reason? I think some damping property is given by the core material.

Pafi said:Do you mean this way? (attached) This has a very low Al value, you needed a very large number of turns, and this leeds to high loss, and yet the stray field wont be low really. You'd better cut the toroids into quarters (or smaller parts), join them back together with 0.3...0.8 mm gaps, and wind it normally. It's good to leave the areas over the gaps free of wires, but not neccessary.

High Q is not a problem for class D audio output filter, but a requirement.

In a gapped toroid, the magnetic field bulges externally at each gap. I've noticed that in images of a straight coil, the field remains inside the coil except at the ends.

I wonder why iron powder is preferred to gapped ferrite besides magnetic field containment. Could that be the only reason? I think some damping property is given by the core material.

Attachments

Electrone!

Yes, but the smaller the gap, the lower the bulge. This because I use 4 smaller gaps instead of 1 big. Additionally: magnetic forces of the opposite gaps cancels (more-or-less) each other when you are relatively far from the core. This has much less leakage then an air-core has, and also it has significantly lower loss (at moderate freq).

OK, but with this arrangement you get a very low Al also. Why is it any better then an air-core toroid (wich is also unusable at this freq because of too low Al)?

Because no manufacturer makes ferrite toroid slices.

In a gapped toroid, the magnetic field bulges externally at each gap.

Yes, but the smaller the gap, the lower the bulge. This because I use 4 smaller gaps instead of 1 big. Additionally: magnetic forces of the opposite gaps cancels (more-or-less) each other when you are relatively far from the core. This has much less leakage then an air-core has, and also it has significantly lower loss (at moderate freq).

I've noticed that in images of a straight coil, the field remains inside the coil except at the ends.

OK, but with this arrangement you get a very low Al also. Why is it any better then an air-core toroid (wich is also unusable at this freq because of too low Al)?

I wonder why iron powder is preferred to gapped ferrite besides magnetic field containment.

Because no manufacturer makes ferrite toroid slices.

Originally posted by Pafi

Electrone!

Yes, but the smaller the gap, the lower the bulge. This because I use 4 smaller gaps instead of 1 big. Additionally: magnetic forces of the opposite gaps cancels (more-or-less) each other when you are relatively far from the core. This has much less leakage then an air-core has, and also it has significantly lower loss (at moderate freq).

I've made air core class D output inductors as in the diagram, but without the ferrite ends, and with the adjacent coils touching, for my experimental projects. I've thought a similar thing about those stray fields canceling at a distance.

OK, but with this arrangement you get a very low Al also. Why is it any better then an air-core toroid (wich is also unusable at this freq because of too low Al)?

I've tried air core toroids, but they are harder to wind as with other ones. I think i am going to try an output choke that is just 10uH. It is easy to wind on a straight former like a stick pen.

Because no manufacturer makes ferrite toroid slices.

Ahh!

Re: Re: Re: Re: Hybrid Output Inductor

The iron powder crossover toroids from danish DCA and maybe also Jantzen are supposed to be of a special mix that holds air and works like airgap

But those are usually very big

Im not sure whether other makes work the same way, but I dont think so

The smaller common ones in question here I reckon are the same used fore small noise chokes fore mains filter

I dont think they are special

Electrone said:

I wonder why iron powder is preferred to gapped ferrite besides magnetic field containment. Could that be the only reason? I think some damping property is given by the core material.

The iron powder crossover toroids from danish DCA and maybe also Jantzen are supposed to be of a special mix that holds air and works like airgap

But those are usually very big

Im not sure whether other makes work the same way, but I dont think so

The smaller common ones in question here I reckon are the same used fore small noise chokes fore mains filter

I dont think they are special

I've made air core class D output inductors as in the diagram, but without the ferrite ends, and with the adjacent coils touching, for my experimental projects.

Had it high Q? Had it low DCR? Was it small?

I've thought a similar thing about those stray fields canceling at a distance.

And you were right, but your initial field strength were huge, and cancellation is not perfect (generally). A small gap has much smaller leakage.

It is easy to wind on a straight former like a stick pen.

OK, but what will hold it during usage?

tinitus!

The iron powder crossover toroids from danish DCA and maybe also Jantzen are supposed to be of a special mix that holds air and works like airgap

Every iron powder core contains "distributed gaps", but they have one ore more of the following drawback:

- expensive (or very expensive)

- high loss

- too small Al

- reduced effective area (at 0.3...0.5 Tesla the permeability starts to fall)

Re: Re: Re: Re: Re: Hybrid Output Inductor

Indeed, there are a lot of different compositions of iron core types, but when I tested several different ones, only the red type 2 from Amidon seemed to work acceptably. I just tried the offerings of the one company.

tinitus said:

The iron powder crossover toroids from danish DCA and maybe also Jantzen are supposed to be of a special mix that holds air and works like airgap

But those are usually very big

Im not sure whether other makes work the same way, but I dont think so

The smaller common ones in question here I reckon are the same used fore small noise chokes fore mains filter

I dont think they are special

Indeed, there are a lot of different compositions of iron core types, but when I tested several different ones, only the red type 2 from Amidon seemed to work acceptably. I just tried the offerings of the one company.

Pafi said:

Had it high Q? Had it low DCR? Was it small?

Air cores generally have high Q, I'd say. It was composed of about 90 inches of 20 gauge wire. It wasn't real small though, being composed of a coil 2cm in diameter and 8cm long that was then folded back at half its length.

And you were right, but your initial field strength were huge, and cancellation is not perfect (generally). A small gap has much smaller leakage.

I'm glad that we get some things right to lessen the misery in life.

OK, but what will hold it during usage?

Epoxy might work.

Air cores generally have high Q, I'd say.

Yes, air have very high Q, but what about the complete coil? The magnetic field penetrates hardly into the wire, and causes high loss, which can be (occasionally much) more then the loss caused by resistance of the wire. It forms an induction heater which heats itself (at least the inner side of the wires)!

It was composed of about 90 inches of 20 gauge wire. It wasn't real small though, being composed of a coil 2cm in diameter and 8cm long that was then folded back at half its length.

I don't really understand. On 2 cm diameter a turn is 6.5 cm. 90 inch is about 35 turns. If one turn is 0.85 mm, then 35 turns can form a coil with 30 mm length. Why is it 80 mm long?

This arrangement (with ferrite terminators) has about Al=5. I'd expect 4...10 times more Al for a good inductor.

Epoxy might work.

Can you do it faster then winding a toroid?

I hate epoxy gluing. It's flowing everywhere you don't want until it sets. It needs special care.

Originally posted by Pafi

Yes, air have very high Q, but what about the complete coil? The magnetic field penetrates hardly into the wire, and causes high loss, which can be (occasionally much) more then the loss caused by resistance of the wire. It forms an induction heater which heats itself (at least the inner side of the wires)!

True, which is why they are only one layer.

I don't really understand. On 2 cm diameter a turn is 6.5 cm. 90 inch is about 35 turns. If one turn is 0.85 mm, then 35 turns can form a coil with 30 mm length. Why is it 80 mm long?

I was just using it as a rough example from memory. Sorry you expected it to be accurate in specifics!

This arrangement (with ferrite terminators) has about Al=5. I'd expect 4...10 times more Al for a good inductor.

A good inductor is one that does the job. It did it for me better than other things that I had tried.

Can you do it faster then winding a toroid?

Much faster, and the wire isn't damaged and can be reused during experimentation.

I hate epoxy gluing. It's flowing everywhere you don't want until it sets. It needs special care.

I would consider using polymide tape. How do you hold your ferrite pieces together? I might try the ferrite quarters.

I have been thinking of another air core inductor construction method. But this idea might not involve using ferrite. Wind some hundreds of wire turns on a dowel rod. Then slide off the coil and spiral it so that the ends come together. After some more thought, I realized that it isn't completely different from the technique used to give tungsten light bulb filaments a compact structure, like the DNA molecule, even.

This structure would not provide a contained magnetic field as well as the iron in a toroid does. Yet I seem to find the concept of interest.

My mind keeps revisiting the theory of amplifiers even though i have realized that i don't want to re-establish an audio system. Amplifier design is somewhat like playing chess. It has an attraction because it is infinitely variable, yet somehow comforting to focus the mind on.

This structure would not provide a contained magnetic field as well as the iron in a toroid does. Yet I seem to find the concept of interest.

My mind keeps revisiting the theory of amplifiers even though i have realized that i don't want to re-establish an audio system. Amplifier design is somewhat like playing chess. It has an attraction because it is infinitely variable, yet somehow comforting to focus the mind on.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Class D

- Hybrid Output Inductor