Is the VGA connector the inputs ? where are they coming from on the device mounted to the wall?

VGA connector i used as output connector (for 5 satellite speakers). just i thought the cabling will be clean.

Kuldeep Singh, I would not mount electrolytic caps with their expansion gaps (tops) pressed up against a surface!

true... but this was quick and easy... and anyway the same setup (caps) i was using from last 2 yrs without any change in dimensions of caps...

An externally hosted image should be here but it was not working when we last tested it.

and this time i even put the bleeder resistors on top... earlier even they were not there

Again, to avoid double posting, here's a link to the photo story/review of a BPA-150 project I'm working on.

http://www.diyaudio.com/forums/group-buys/137430-bpa300-round-2-a-115.html#post2710763

Having mucho fun!

http://www.diyaudio.com/forums/group-buys/137430-bpa300-round-2-a-115.html#post2710763

Having mucho fun!

Hello guys. There is some very nice work on here! I got the diy audio bug and decided to build a Gainclone as my first serious project. I chose the LM3886 from chipamp.com.

Muddobber--'loved the pics of your build, in posting #1724. I thought you'd like to meet it's Class A "brother"--a Pass DIY F5 that I was building at the same time you were building your chipamp...... very similar construction philosophy...! (Nice job on your amp....I was going for a "new retro" look on mine)

Sorry--no intent to hijack this thread..... In fact, my next project is an LM3886 amp....!

Attachments

Chipamp just lift off from the kitchen table:

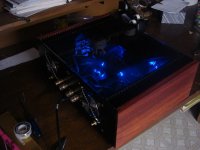

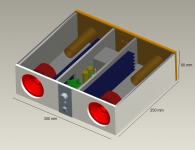

OPA 549, 2x 100VA trafo ; +-25V DC; 22 000uf per rail. Non Inverting config, thanks forum member Alcaid for PCB layout.

Enclosure aluminium top cover still need polishing and M6 100mm screws (ordered).

In addition to the wooden enclosure came eight meat boards

Sounds nice, no hum - i will compare it with my LM3875 NI and take some measurements with scope and sound-card tomorrow.

Oscar sweeeet ...

Chipamp just lift off from the kitchen table:

*SNIP*

OPA 549, 2x 100VA trafo ; +-25V DC; 22 000uf per rail. Non Inverting config, thanks forum member Alcaid for PCB layout.

Enclosure aluminium top cover still need polishing and M6 100mm screws (ordered).

In addition to the wooden enclosure came eight meat boards

Sounds nice, no hum - i will compare it with my LM3875 NI and take some measurements with scope and sound-card tomorrow.

A tip:

Next time you work with baltic birch, or any other ply, turn each layer of ply so they are oriented 90 degrees to the previous layer. You won't get the doubled layer ply effect happening between each separate layer.

Brendan

I just looked through about 50 pages of this thread and ....wow these are amazing. I have been wondering where can I find out how to build a simple high quality amplifier for a set of full range speakers? Maybe 30watts not sure.

I would love to someday make a 5 channel power amp but lets not get carried away. I figured most of these amps are better sound quality than my Denon AVR can produce but I will use that for HT. I have done plenty of soldering before so that's at least one skill I have.

Oh yah and I am hoping that I could make something that doesn't cost $1000 for a first amp. I had been on the 41hz forum and asking for awhile but had other things come up and its been a few years now.

So I am back here and saw this thread and figured there's enough knowledge here to help me figure out something.

Thanks

Osscar those are some amazing amps you got there.

I would love to someday make a 5 channel power amp but lets not get carried away. I figured most of these amps are better sound quality than my Denon AVR can produce but I will use that for HT. I have done plenty of soldering before so that's at least one skill I have.

Oh yah and I am hoping that I could make something that doesn't cost $1000 for a first amp. I had been on the 41hz forum and asking for awhile but had other things come up and its been a few years now.

So I am back here and saw this thread and figured there's enough knowledge here to help me figure out something.

Thanks

Osscar those are some amazing amps you got there.

Chipamp just lift off from the kitchen table:

OPA 549, 2x 100VA trafo ; +-25V DC; 22 000uf per rail. Non Inverting config, thanks forum member Alcaid for PCB layout.

Enclosure aluminium top cover still need polishing and M6 100mm screws (ordered).

In addition to the wooden enclosure came eight meat boards

Sounds nice, no hum - i will compare it with my LM3875 NI and take some measurements with scope and sound-card tomorrow.

Spikes on an amp??

I just don't get it...

repeating the pics from a previous post.

I just don't get it...

I hope the vented enclosures and the 3" drivers give lots of cool air over the two enclosed heatsinks that are oriented the wrong way to dissipate heat effectively.

I too hope the same thing

A chipamp I built with LM3875's and chinese boards (I assume). The LM's are attached to an aluminum block as a solid base and sink at the same time.

Volume pot bought as a kit and soldered myself, exposed as a design element.

Volume pot bought as a kit and soldered myself, exposed as a design element.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Which I wouldn't want to get dusty by leaving it exposed.A chipamp I built with LM3875's and chinese boards (I assume). The LM's are attached to an aluminum block as a solid base and sink at the same time.

Volume pot bought as a kit and soldered myself, exposed as a design element.

No additional smoothing?

Frank

- Home

- Amplifiers

- Chip Amps

- Chip Amp Photo Gallery