Hi Andre.  Thanks for your kind words, and the nice build! What a nice amp! I hope it serves you very well.

Thanks for your kind words, and the nice build! What a nice amp! I hope it serves you very well.

Wow! What a good job. You hit on a key point. We fully expected people woud like to use bigger/better input caps. We know that the stock caps are very good, but we also know there are many better. You illustrate beutifully how easy it is to use them off the PCB.

Excellent work! I would write more but I have to head off to see a friend.

What a nice way to bring in the new year.

BTW this month marks the 1st year of my involvemnt in DIY audio. Seems like a lot has happened in one year, but as everyone else knows the journey is endless.

Cheers!

Russ

Wow! What a good job. You hit on a key point. We fully expected people woud like to use bigger/better input caps. We know that the stock caps are very good, but we also know there are many better. You illustrate beutifully how easy it is to use them off the PCB.

Excellent work! I would write more but I have to head off to see a friend.

What a nice way to bring in the new year.

BTW this month marks the 1st year of my involvemnt in DIY audio. Seems like a lot has happened in one year, but as everyone else knows the journey is endless.

Cheers!

Russ

Nice work Andre. Takes a lot of effort to execute such a fine example--and it sounds great too - what we are all after.

Thanks guys for the soldering tips.

I think I found the reason for the ineffective heat transfer.

A website stated Wonder solder has a melting point of 380F and needs the soldering iron temperature to be set to 750F for optamum flow. I had the tip temperature set at 626f (330C), which is about right for mormal resin core solder. It stated that soldering is quicker with Wonder solder than with most other types.

I'll give the higher temp. a trial.

Audie.

Thanks guys for the soldering tips.

I think I found the reason for the ineffective heat transfer.

A website stated Wonder solder has a melting point of 380F and needs the soldering iron temperature to be set to 750F for optamum flow. I had the tip temperature set at 626f (330C), which is about right for mormal resin core solder. It stated that soldering is quicker with Wonder solder than with most other types.

I'll give the higher temp. a trial.

Audie.

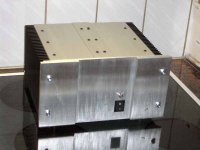

...and the front panel

Hi Russ,

For the input cap it is clear that it would blow up the current PC board dimensions too much, if a wider variety of more "exotic" types shall obtain the necessary space to fit. One can still easily mount the input cap externally, if required.

I am more concerned with the diode bridge, that may get replaced with single diodes (FREDs), when the V1.1 version gets available. That should be the "icing on the cake". Well... The journey never ends, does it?

Anyway, the result is excellent sounding as is, I am not so sure what further tweaking of the circuit could bring - the sound is relaxed and there is no midrange glare or any harshness, which kind of stands proof that the standard diode bridge does a good job already....

I have yet to try this amp with bigger speakers - the Piegas only serve for initial testing. I wonder how the sound holds together with boxes that feature a "real" woofer, where (more) control over back EMF is required.

So far so good, I attach a pic of the front plate that still needs a "top chop", it is about 6mm too high now. I also have to recess the mounting screws. Then the plate gets sanded and coated with transparent paint - and I am all done.

I am off Wednesday morning this week to attend the CES in Vegas, so completing the amp has to wait at least another week.

Cheers

Andre

Hi Russ,

For the input cap it is clear that it would blow up the current PC board dimensions too much, if a wider variety of more "exotic" types shall obtain the necessary space to fit. One can still easily mount the input cap externally, if required.

I am more concerned with the diode bridge, that may get replaced with single diodes (FREDs), when the V1.1 version gets available. That should be the "icing on the cake". Well... The journey never ends, does it?

Anyway, the result is excellent sounding as is, I am not so sure what further tweaking of the circuit could bring - the sound is relaxed and there is no midrange glare or any harshness, which kind of stands proof that the standard diode bridge does a good job already....

I have yet to try this amp with bigger speakers - the Piegas only serve for initial testing. I wonder how the sound holds together with boxes that feature a "real" woofer, where (more) control over back EMF is required.

So far so good, I attach a pic of the front plate that still needs a "top chop", it is about 6mm too high now. I also have to recess the mounting screws. Then the plate gets sanded and coated with transparent paint - and I am all done.

I am off Wednesday morning this week to attend the CES in Vegas, so completing the amp has to wait at least another week.

Cheers

Andre

Attachments

Re: ...and the front panel

Hi Andre

very nice looking implementation...

Are you sure it sounds as good in the finished metal box as it did before you put the lid & front panels on ?

Just a thought - others here have noticed that the final metal panel spoiled the sound ?

I hope not - for your sake...

cheers

mike

Hi Andre

very nice looking implementation...

Are you sure it sounds as good in the finished metal box as it did before you put the lid & front panels on ?

Just a thought - others here have noticed that the final metal panel spoiled the sound ?

I hope not - for your sake...

cheers

mike

Re: Re: ...and the front panel

Are you serious?

mikelm said:

Just a thought - others here have noticed that the final metal panel spoiled the sound ?

I hope not - for your sake...

Are you serious?

metal front panels...

kill the sound???? Shouldn't we bettter ask Nelson - he should definitely know better!!!?

Well Mike, I can't tell for sure - I have not listened to the amp when the front panel was on....

Nice joke anway... I do not believe in so many things that are discussed in certain "audiophile circles". Most of the things postulated just don't make any sense.

Shouldn't blue LEDs be detrimental to the sound qquality as well, I read this here somewhere haha!!??

Before I eject myself: The front panel is 12mm thick aluminum on the sides - difficult to cut at home. That is the reason why I am not yet completely done with it.

I'll switch my notebook off, it's pretty late on my side of the globe already.

Bests

Andre

kill the sound???? Shouldn't we bettter ask Nelson - he should definitely know better!!!?

Well Mike, I can't tell for sure - I have not listened to the amp when the front panel was on....

Nice joke anway... I do not believe in so many things that are discussed in certain "audiophile circles". Most of the things postulated just don't make any sense.

Shouldn't blue LEDs be detrimental to the sound qquality as well, I read this here somewhere haha!!??

Before I eject myself: The front panel is 12mm thick aluminum on the sides - difficult to cut at home. That is the reason why I am not yet completely done with it.

I'll switch my notebook off, it's pretty late on my side of the globe already.

Bests

Andre

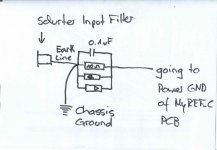

Ground loop breaker circuit

Hi Andre,

really nice amp, congratulations!

I also had problems with ground loop induced hum in other audio projects (mono amplifiers).

Do you have a circuit diagram of your ground loop breaker?

The LM3886 RefC will be my next DIY Amp, perhaps I can use your circuit also.

Brian,

What is the maximum size (diameter) of 10.000µF capacitors I can use with the TP Boards? Do Slit-Foils (35/40 mm diamater) match?

Regards

Arne

Hi Andre,

really nice amp, congratulations!

I also had problems with ground loop induced hum in other audio projects (mono amplifiers).

Do you have a circuit diagram of your ground loop breaker?

The LM3886 RefC will be my next DIY Amp, perhaps I can use your circuit also.

Brian,

What is the maximum size (diameter) of 10.000µF capacitors I can use with the TP Boards? Do Slit-Foils (35/40 mm diamater) match?

Regards

Arne

Re: Re: Re: ...and the front panel

Hi Russ

Well - serious in a non-serious kind of way...

kind of amused open mindedness

I have not heard this myself but I make my amps casings from wood... ...which I prefer to work with

...which I prefer to work with

There are two sources, that I can think of, of people that noticed this.

Denis moorcroft of UK who makes DNM amplifiers that sell at around £5000 with very good reputation - after extensive listening tests, decided to use as little metal as possible - his casings are acrylic

Also AnalogSA, of this forum, left the heavy aluminum lid of his chip amp perched diagonally on the top of the rest of his heavy aluminum box because when noticed when he actually fitted it "properly" the sound deteriorated.

Andre's nice box reminded me of this as it has the same solid aluminium build - hence the question.

Hi Andre,

I was not expecting you to believe ( one way or the other ) I was just wondering if you noticed any difference. Because I prefer wood this is one listening test I may not get around to doing...

cheers

mike

Russ White said:

Are you serious?

Hi Russ

Well - serious in a non-serious kind of way...

kind of amused open mindedness

I have not heard this myself but I make my amps casings from wood...

There are two sources, that I can think of, of people that noticed this.

Denis moorcroft of UK who makes DNM amplifiers that sell at around £5000 with very good reputation - after extensive listening tests, decided to use as little metal as possible - his casings are acrylic

Also AnalogSA, of this forum, left the heavy aluminum lid of his chip amp perched diagonally on the top of the rest of his heavy aluminum box because when noticed when he actually fitted it "properly" the sound deteriorated.

Andre's nice box reminded me of this as it has the same solid aluminium build - hence the question.

Hi Andre,

I was not expecting you to believe ( one way or the other ) I was just wondering if you noticed any difference. Because I prefer wood this is one listening test I may not get around to doing...

cheers

mike

I believe it is best not to believe or disbelieve - just go by experience

Agree. Just take in others views/experiences without either believing or disbelieving. Your own experience is what matters.

Peoples perceptions of the same sound will vary from person to person. Because one person hears a difference that another does not, does not mean that there wasn't a difference.

Airing ones experience (in a Forum for example) will often spark a debate/argument because others will disagree with that experience, since they themselves have not experienced it.

That is why some are reluctant to post their experience (of the Rev C for example), knowing it could spark an argument.

A.

What is the maximum size (diameter) of 10.000µF capacitors I can use with the TP Boards?

30mm is the largest diameter. I know you can also find at least 12000 in that size.

Re: belief ?

Hi Mike, I meant no disrespect, but the question just struck me funny. Best Reards.

Best Reards.

Cheers!

Russ

mikelm said:...Come to think of it, seems to me that disbelief is just another belief...

I believe that it is best not to believe or disbelieve - just go by experience.

This is my belief ... and I'm sticking to it !!!

Hi Mike, I meant no disrespect, but the question just struck me funny.

Cheers!

Russ

Grounding Loop Breaker Circuit

and in return to 1543:

Take a look at this link:

http://sound.westhost.com/earthing.htm

Rod Elliot has something to say about earthing in general - highly recommended read. States a couple of important points to consider (don't get fried by live lines) - and the ground breaker circuit I used is a simple one used by others as well. It does work well in my specific amp implementation using MyRef_C boards from TP audio, but your mileage may vary - simply because grounding issues are a very individual thing to deal with. Hope this info helps. Important: For the 0.1uF cap you better deploy a high voltage type (I used 400VAC), as the cap eventually sees line voltage and may go bang is a 100V type is used. Furthermore I used a 10W resistor as well as two 600V rated diodes.

For the thing Mike throws up, I can only add I do not like wooden housings at all (for their "baroque" looks!!!) - maybe with the exception of a Lyra Connoisseur preamp, that is well built and good looking, but the price tag... Ouch!

Aluminum is non magnetic, so the influence on sound might be negligible - and if it was a factor to consider for the sonics in general, well I am sure we would only see high end gear coming in wooden enclosures, as if this really makes a difference who would not try to take advantage of it. Especially where it counts... But on the other hand: One might be tempted to just TEST and compare something, to see if it does influence sound or not - as anticipating results based on exisiting scientific knowledge (sometimes) doesn't bring us any further. Scientific ground work also includes lots of accidential discoveries.....

Bests

Andre

and in return to 1543:

Take a look at this link:

http://sound.westhost.com/earthing.htm

Rod Elliot has something to say about earthing in general - highly recommended read. States a couple of important points to consider (don't get fried by live lines) - and the ground breaker circuit I used is a simple one used by others as well. It does work well in my specific amp implementation using MyRef_C boards from TP audio, but your mileage may vary - simply because grounding issues are a very individual thing to deal with. Hope this info helps. Important: For the 0.1uF cap you better deploy a high voltage type (I used 400VAC), as the cap eventually sees line voltage and may go bang is a 100V type is used. Furthermore I used a 10W resistor as well as two 600V rated diodes.

For the thing Mike throws up, I can only add I do not like wooden housings at all (for their "baroque" looks!!!) - maybe with the exception of a Lyra Connoisseur preamp, that is well built and good looking, but the price tag... Ouch!

Aluminum is non magnetic, so the influence on sound might be negligible - and if it was a factor to consider for the sonics in general, well I am sure we would only see high end gear coming in wooden enclosures, as if this really makes a difference who would not try to take advantage of it. Especially where it counts... But on the other hand: One might be tempted to just TEST and compare something, to see if it does influence sound or not - as anticipating results based on exisiting scientific knowledge (sometimes) doesn't bring us any further. Scientific ground work also includes lots of accidential discoveries.....

Bests

Andre

Attachments

I wonder how critical the value on that cap is though, I admit I have been using a 100V and it does work, but I get what you are saying, could I use a 470nf cap there? (only x2 one I have)

Gotta disagree with you on the wood though, but I'll give you credit, the darker woods are very out of fashion... still there are tonnes of light woods, like white oak, maple, yellowwood...

Gotta disagree with you on the wood though, but I'll give you credit, the darker woods are very out of fashion... still there are tonnes of light woods, like white oak, maple, yellowwood...

Cap Value

Hello Nordic,

I don't think the capacitor value is that critical - use what you have at hand, from like 50nF to 470nF - 0.1 uF is what I see in several explanations found online. Everybody copies from everybody, or so it seems....

But the voltage rating of this cap does make a difference. It does work as long as everything is OK. But if there is a problem and line voltage creeps in and sets the chassis under 230V AC, i. e. because of transformer breakdown or internal shortcut caps with 100VAC tend to go boom quickly in such cases. Depends what fails first, the 10W resistor or the (underspec'd) capacitor. Or both, haha.

The cap only serves to shield or ground the housing - thus eliminating RFI and other crap from the outside (i.e. cell phones and HF garbage). Read the Rod Elliot article.....

Bests

Andre

Hello Nordic,

I don't think the capacitor value is that critical - use what you have at hand, from like 50nF to 470nF - 0.1 uF is what I see in several explanations found online. Everybody copies from everybody, or so it seems....

But the voltage rating of this cap does make a difference. It does work as long as everything is OK. But if there is a problem and line voltage creeps in and sets the chassis under 230V AC, i. e. because of transformer breakdown or internal shortcut caps with 100VAC tend to go boom quickly in such cases. Depends what fails first, the 10W resistor or the (underspec'd) capacitor. Or both, haha.

The cap only serves to shield or ground the housing - thus eliminating RFI and other crap from the outside (i.e. cell phones and HF garbage). Read the Rod Elliot article.....

Bests

Andre

Re. TRT wonder Solder.

Increasing the soldering iron temperature to 750F/399C as advised, did the trick. The solder flows very quickly now, making soldering effortless, as was promised.

It's now no problem soldering the component side, as others are doing, i f needed.

The solder I'm using is over 10 years old. I don't know if it is different to the Wonder Solder Clear that I have seen mentioned lately. I discovered that Twisted Pear Design? use it to solder their cables.

Audie.

Increasing the soldering iron temperature to 750F/399C as advised, did the trick. The solder flows very quickly now, making soldering effortless, as was promised.

It's now no problem soldering the component side, as others are doing, i f needed.

The solder I'm using is over 10 years old. I don't know if it is different to the Wonder Solder Clear that I have seen mentioned lately. I discovered that Twisted Pear Design? use it to solder their cables.

Audie.

Loop Breaker Circuit

Hi Andre,

very interesting stuff at http://sound.westhost.com/earthing.htm. With that background hum problems shold not occur anymore.

TXH!

Arne

Hi Andre,

very interesting stuff at http://sound.westhost.com/earthing.htm. With that background hum problems shold not occur anymore.

TXH!

Arne

Re: Grounding Loop Breaker Circuit

Hi Andre

Afaik the Connoisseur is not made of wood but carved out of a solid aluminium billet. If there is a wood appearance it's only decorative, on the outside. It will still help improve the resonant signature of alu.

Wooden enclosures are quite unsuitable for commercial electronic production. Most importantly a wooden amp/preamp won't comply with basic electic safety regulations, it will be a potential fire hazard and unless the inside is somehow treated to achieve screening it make the circuits susceptible to EMI.

The relatively small sound advantage is just not worth the trouble commercially.

When a manufacturer makes the slightest, most pathetic effort to address microphony, say by mounting a pcb on rubber grommets or simply glueing some foam to a lid, we always learn about this from the marketing department

AndreG said:

For the thing Mike throws up, I can only add I do not like wooden housings at all (for their "baroque" looks!!!) - maybe with the exception of a Lyra Connoisseur preamp, that is well built and good looking, but the price tag... Ouch!

Aluminum is non magnetic, so the influence on sound might be negligible - and if it was a factor to consider for the sonics in general, well I am sure we would only see high end gear coming in wooden enclosures, as if this really makes a difference who would not try to take advantage of it. Especially where it counts...

Bests

Andre

Hi Andre

Afaik the Connoisseur is not made of wood but carved out of a solid aluminium billet. If there is a wood appearance it's only decorative, on the outside. It will still help improve the resonant signature of alu.

Wooden enclosures are quite unsuitable for commercial electronic production. Most importantly a wooden amp/preamp won't comply with basic electic safety regulations, it will be a potential fire hazard and unless the inside is somehow treated to achieve screening it make the circuits susceptible to EMI.

The relatively small sound advantage is just not worth the trouble commercially.

When a manufacturer makes the slightest, most pathetic effort to address microphony, say by mounting a pcb on rubber grommets or simply glueing some foam to a lid, we always learn about this from the marketing department

- Home

- Amplifiers

- Chip Amps

- My "audiophile" LM3886 approach