That you use on all of your chassis. It looks like a countersunk washer that you can use in order to get some flexibility by drilling your holes a bit larger. Into the countersunk washer fits you cool screw.

Where do you get those? I would be very interested in buying the washers alone for some size 8 counter-sunk screws.

Thank you,

Paul Hilgeman

Where do you get those? I would be very interested in buying the washers alone for some size 8 counter-sunk screws.

Thank you,

Paul Hilgeman

It is a high tolerance brass bushing with 0.25 inside hole and 0.50 mounting hole. It accepts shallow counersink screws.

I don't use them much, mostly in the preamp, but I'm running out of them quickly. They come form aircraft industry and I would be interested myself, where to source more of those.

I don't use them much, mostly in the preamp, but I'm running out of them quickly. They come form aircraft industry and I would be interested myself, where to source more of those.

Attachments

Peter Daniel said:It is a high tolerance brass bushing with 0.25 inside hole and 0.50 mounting hole. It accepts shallow counersink screws.

I don't use them much, mostly in the preamp, but I'm running out of them quickly. They come form aircraft industry and I would be interested myself, where to source more of those.

You might http://www.interfast.ca

Cheer,

Francois.

Of course, I have impact guns. I even have an offset collar installation tool (by Atlas)

And I have some local friends who currently work in the industry, but I'm always on a lookout for nice fasteners.

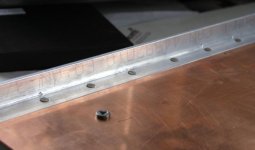

I somehow never thought about using Hi-Lites in chassis building, but maybe it's something to think about. I used rivets recently, and I'm very satisfied with results.

They are not sqeezed too tight, I made counersink for lower manufactured head size

And I have some local friends who currently work in the industry, but I'm always on a lookout for nice fasteners.

I somehow never thought about using Hi-Lites in chassis building, but maybe it's something to think about. I used rivets recently, and I'm very satisfied with results.

They are not sqeezed too tight, I made counersink for lower manufactured head size

Attachments

Peter Daniel said:Of course, I have impact guns. I even have an offset collar installation tool (by Atlas)

And I have some local friends who currently work in the industry, but I'm always on a lookout for nice fasteners.

I somehow never thought about using Hi-Lites in chassis building, but maybe it's something to think about. I used rivets recently, and I'm very satisfied with results.

They are not sqeezed too tight, I made counersink for lower manufactured head size

Let me know if you want some, I will make you a good price but without any tracability (That the reason I'm able to sell it =)).

I will check the quantity I have in stock.

Peter Daniel said:Here's the other side. It will be sanded. so the rivets would be barely visible.

Why don't you just shave it? will give a even better finish no? That what we do here on Bombardier wing plank when we install interference fit freeze bushing to repair some damaged holes.

Coulomb said:If you use a Dewalt Pilot drill after you drill with a standard drill for the rivet hole, you will get a nice little ledge to catch the Rivet head and have it flush to the material surface.

We prefer to use more advanced tools

BTW, the list price of that pistol drill gun is close to $1K, if not more.

Attachments

Peter Daniel said:Micro shaver is about the only tool I don't have, but the aluminum parts have to be brushed and sanded anyway (for better appearance).

Check on ebay, there very cheap. I got two (one zephir and one magnavon) and 10 countersink bits for 10$US+transport.

Here one:

http://cgi.ebay.ca/ws/eBayISAPI.dll?ViewItem&item=3801343532&category=25259

and here one with shaver bits:

http://cgi.ebay.ca/ws/eBayISAPI.dll?ViewItem&item=3801348208&category=25259

Peter Daniel said:

We prefer to use more advanced tools

BTW, list price for that pistol drill gun is close to $1K, if not more.

As I see you already have a microstop =) You only need the shaver bit =)

Peter Daniel said:Actually, I was thinking about complete gun, they make them really nice and small. It is still $500 though

=) Yeah, but for my usage I would only buy a shaver bit. I don't need a other gun or the stabiliser. I don't shave enought rivet to make this kind of expense. =)

I find yardstore.com to be a very good and competetive supplier of tooling and accesories (both new and used)

http://www.yardstore.com/

http://www.yardstore.com/

Here is some specification on the Hi-lite:

Material: 6AL-4V Titanium Alloys per Spec. AMS4928 or AMS4967

Heat Treat: 95,000 PSI Shear minimum

Here the complete specification

http://www.hi-shear.com/standards/hst10.pdf

Material: 6AL-4V Titanium Alloys per Spec. AMS4928 or AMS4967

Heat Treat: 95,000 PSI Shear minimum

Here the complete specification

http://www.hi-shear.com/standards/hst10.pdf

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Peter Daniel What type of fasteners are those?