I plan on making this chassis specifiacally for GC amp. If this order will go through well, we can later think about some other chassis styles for different purposes.

BTW, I'm not thinking of making it myself, but it would go through the company that does some work for Bryston, Magnum Dynalab, Sim Audio and even recently they were bidding on ML preamp

So the chassis would have the slots milled out in the top cover and silk screening on front and rear panels. Everything would be CNC machined. So we better think it over, to make the best out of it. I need to order at least 25 sets to get substantial discount.

BTW, I'm not thinking of making it myself, but it would go through the company that does some work for Bryston, Magnum Dynalab, Sim Audio and even recently they were bidding on ML preamp

So the chassis would have the slots milled out in the top cover and silk screening on front and rear panels. Everything would be CNC machined. So we better think it over, to make the best out of it. I need to order at least 25 sets to get substantial discount.

Peter,

"If you build it they will come"

The 2 knob idea is growing on me, and since most want two, I'd be happy with that. especially with all the options you've mentioned, I dont see how we could do any better. I cant even think what mine would look like if I tried to build one for the first time.

"If you build it they will come"

The 2 knob idea is growing on me, and since most want two, I'd be happy with that. especially with all the options you've mentioned, I dont see how we could do any better. I cant even think what mine would look like if I tried to build one for the first time.

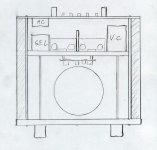

Here's proposed layout. The main frame is H shaped, with front and rear panels attached to it. Volume pot and switch have shaft extenders. Rectifiers board is mounted in the same compartment as transformer, vertically. Amp boards are on the opposite side. RCA inputs are in the center part of rear panel and binding posts are on the outside. Initially, I wanted to place amp boards on side panels, but the physical distance was to large and the wiring would be a mess. Another option would be placing cross bar (from center plate to rear panel) and mounting both chips to that. This would allow for true dual mono configuration, the only problem is running wires from inputs to selector switch. Both pots, switch and transformer will allow a lot of substitutions as there will be enough space. I added wood panels on the sides, as I needed something here to fill that useless space created by the knobs being reasonably spaced off the sides. This will also reduce the size of top panel, wiich usually introduces most resonances. One reason for that was also adding the inside cross panel. It provides sort of shileding from transformer, allows mounting of pot and switch, but what's most important, it also prevents top panel from excessive resonances. It might be interesting to use a perforated aluminum for that purpose, but it's mostly up to you, as a slotted, 1/8" top cover can be also made at reasonable cost.

All comments and suggestions are welcome.

All comments and suggestions are welcome.

Attachments

Some thougts:

I have seen the AC inlets placed right next to the trafo on the bottom side of the box, (this would ofcourse need a 90degree IEC plug to work) and its not very versatile but i think its a cool arrangement

If it where possible to place the selector and pot behind the GC boards they could be placed closer together making wiring simpler (and shorter) and the box thinner but there are ofcourse some drawbacks with that arrangement.

With woodensides there will probobly be lots of request for different woods. maybe best to leave that part to the builder?

Can you give us a price and/or weight spec at this time? or atleast a guess it would be much appricieated.

/ Mikael

I have seen the AC inlets placed right next to the trafo on the bottom side of the box, (this would ofcourse need a 90degree IEC plug to work) and its not very versatile but i think its a cool arrangement

If it where possible to place the selector and pot behind the GC boards they could be placed closer together making wiring simpler (and shorter) and the box thinner but there are ofcourse some drawbacks with that arrangement.

With woodensides there will probobly be lots of request for different woods. maybe best to leave that part to the builder?

Can you give us a price and/or weight spec at this time? or atleast a guess it would be much appricieated.

/ Mikael

While two transformers are nice, it makes the chassis much bigger and I would rather go for really true mono in this case: monoblocks. As long as there is a shared switcher for both channels, the wiring won't be simplified that much either.

I also like the attachment of the AC entry module on the bottom, but this requires 1" height on the feet. With a small chassis it may not look good.

I also want to make it smaller than the usual full size chassis. It's a GC, right?

I also like the attachment of the AC entry module on the bottom, but this requires 1" height on the feet. With a small chassis it may not look good.

I also want to make it smaller than the usual full size chassis. It's a GC, right?

hifi said:

Can you give us a price and/or weight spec at this time? or atleast a guess it would be much appricieated.

The weight I will know when it's done. As to the price, I would imagine that for something like that, to have an appeal to a larger audience, it should be more than $150 (USD).

If you really meant true monoblocks, there is a problem with the

way Brian is setting up the power supply board. I don't think it can be split in two. I believe his idea is to have both channels in one box. Of course you can just buy a second circuit board-not a grat expense for people getting this case. But people need to be aware of this to order more boards if I understand you correctly.

re reading the post, I think maybe you meant that IF you had 2 transformers THEN you would go for monoblocks, but in this case you want t o stay with one transformer but TWO channels, Right?

i think Pink mouse was sugesting that the extra holes be drilled part way through from the back, so they would not be seen on the front unless they were later drilled through. I don't think they are essential, even without the extra, partial holes, and with a little care ( and tape on the panel to protect it!) more holes could be drilled by almost anyone. The knob or switch fixing nut hide slight irregularities.

Any chance of offering the attenuator separately? Since you will be ordering a lot already it wouldn't be that much more difficult, and the price for all might go down.

way Brian is setting up the power supply board. I don't think it can be split in two. I believe his idea is to have both channels in one box. Of course you can just buy a second circuit board-not a grat expense for people getting this case. But people need to be aware of this to order more boards if I understand you correctly.

re reading the post, I think maybe you meant that IF you had 2 transformers THEN you would go for monoblocks, but in this case you want t o stay with one transformer but TWO channels, Right?

i think Pink mouse was sugesting that the extra holes be drilled part way through from the back, so they would not be seen on the front unless they were later drilled through. I don't think they are essential, even without the extra, partial holes, and with a little care ( and tape on the panel to protect it!) more holes could be drilled by almost anyone. The knob or switch fixing nut hide slight irregularities.

Any chance of offering the attenuator separately? Since you will be ordering a lot already it wouldn't be that much more difficult, and the price for all might go down.

Variac said:If you really meant true monoblocks, there is a problem with the

way Brian is setting up the power supply board. I don't think it can be split in two. I believe his idea is to have both channels in one box. Of course you can just buy a second circuit board-not a grat expense for people getting this case. But people need to be aware of this to order more boards if I understand you correctly.

re reading the post, I think maybe you meant that IF you had 2 transformers THEN you would go for monoblocks, but in this case you want t o stay with one transformer but TWO channels, Right?

i think Pink mouse was sugesting that the extra holes be drilled part way through from the back, so they would not be seen on the front unless they were later drilled through. I don't think they are essential, even without the extra, partial holes, and with a little care ( and tape on the panel to protect it!) more holes could be drilled by almost anyone. The knob or switch fixing nut hide slight irregularities.

Any chance of offering the attenuator separately? Since you will be ordering a lot already it wouldn't be that much more difficult, and the price for all might go down.

If you to want to do monoblocks, this would require that you use one power supply board per channel pcb. Besides having to purchase an extra set of pcbs, it would work fine.

--

Brian

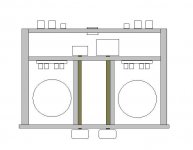

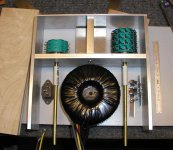

Here's the prototype in progress. The size is 9 x 10 (with wooden panels on). I also managed to find a place for AC socket (if mounted on 0.5 standoffs the feet don't have to be that tall). The rectifier board should be on an opposite side. I tried to make the size as compact as possible, yet allow few different transformers type (Plitron 400 VA will fit too) as well that big Taiwanese volume switch. I will make front panel this time out of 1/4 aluminum, but thicker stock is possible as well. Top and bottom will be 0.2 aluminum.

The only way I can see mounting the chips (in such compact layout) is by using that center bar and the chips would be mounted face to face (the bar is 1/2" thick) . I attached another plate on the bottom to mount the board itself and there is about 0.2 clearance between bottom and top covers to run the wires.

Now, if someone doesn't want to go into source switching, this allows pretty much dual mono configuaration (except for PS).

The only way I can see mounting the chips (in such compact layout) is by using that center bar and the chips would be mounted face to face (the bar is 1/2" thick) . I attached another plate on the bottom to mount the board itself and there is about 0.2 clearance between bottom and top covers to run the wires.

Now, if someone doesn't want to go into source switching, this allows pretty much dual mono configuaration (except for PS).

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Chassis for a group order of non-inverted GC kit?