I have an Alpine F300 4 channel amp with one bad KTD718 output transistor.Does anyone know of a readily available replacement or if perhaps a KTD998 would work as a replacement?Only reason I ask about the KTD998 as a replacement is because I have a few left over from another repair and when I looked at the data sheets the specs for the two transistors looked similiar but maybe I'm missing something.I don't know what specs really matter when trying to find a replacement.

It appears that they're the same piece of silicon in two different packages. The thickness of the transistor under the screw is ~2mm less for the 998 so you need to make sure that the screw doesn't bottom out before the transistor is properly clamped.

Since the 998 is fully insulated, you should remove the original insulator. It would just increase the operating temperature of the transistor. Use heatsink compound between the sink and the transistor.

Since the 998 is fully insulated, you should remove the original insulator. It would just increase the operating temperature of the transistor. Use heatsink compound between the sink and the transistor.

there was quite a bit of grease left from the old part.I just used some of that on the ktd998.I got it soldered in and it seems to be working fine.I'll have to get the amp into my car though to make sure all is well.It tested fine in home but I just want to drop a 4 ohm load on all the channels and try it out bridged at 4 ohms to give it a clean bill of health. Thanks again Perry for your help

It's generally not a good idea to use the old compound. It should all be removed and new compound applied. Ideally, the heatsink compound should flow well so that virtually 100% of it is displaced when the transistor is clamped down. Old compound tends to be dry and will not flow well.

Of course, old compound is probably better than no compound.

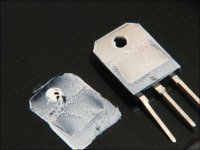

The attached photo shows what the compound should look like when the components are clamped then disassembled. Notice that the layer of compound is so thin it simply looks milky. There's actually more between the components than when they're clamped because some of the displaced compound was pulled back under the transistor as it was lifted. If you're using a compound that doesn't look like this, it's not going to transfer heat as it's designed to do.

Of course, old compound is probably better than no compound.

The attached photo shows what the compound should look like when the components are clamped then disassembled. Notice that the layer of compound is so thin it simply looks milky. There's actually more between the components than when they're clamped because some of the displaced compound was pulled back under the transistor as it was lifted. If you're using a compound that doesn't look like this, it's not going to transfer heat as it's designed to do.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- Transistor replacement for Alpine F300