I know that's bad, bad, bad... Especially when you have all driver's section as SMD's. Traces are burnt together with FET's and gate resistors. No pads to solder resistors anymore

What is my options on fixing this? It's tempting to restore traces with thin wires and then epoxy/glue whole darn thing on surface There must be a better way to do it

There must be a better way to do it

What is my options on fixing this? It's tempting to restore traces with thin wires and then epoxy/glue whole darn thing on surface

valterdaw said:I know that's bad, bad, bad... Especially when you have all driver's section as SMD's. Traces are burnt together with FET's and gate resistors. No pads to solder resistors anymore

What is my options on fixing this? It's tempting to restore traces with thin wires and then epoxy/glue whole darn thing on surfaceThere must be a better way to do it

That's the way to do it.

valterdaw said:I know that's bad, bad, bad... Especially when you have all driver's section as SMD's. Traces are burnt together with FET's and gate resistors. No pads to solder resistors anymore

What is my options on fixing this? It's tempting to restore traces with thin wires and then epoxy/glue whole darn thing on surfaceThere must be a better way to do it

TO-3 is correct, and you can use 1/8 watt resistors for the SMD replacements and use the excess leads as trace replacement. Just a thought. If the board is burnt , then the material has become conductive carbon based material , so you might have to look at removing all the excess burnt PCB material and performing a serious hard wire using the devices lead frame lenghts to replace blasted copper traces. If the thru whole is carboned up, I usually use a exacto knife or dremel tool to drill and scrap away the carbonized material back to undamaged PCB material. Then feed the leads thru and around any contact with the board, so as not to create any short circuit connections.

Its tough work, at best, and sometimes not worth the efforts (Based on the amps real world value).

Good Luck on the salvage operation

valterdaw said:Thanks everyone! Last question: what glue/adhesive will work best for this "operation"?

You can use super glue. It will keep the wires from vibrating loose.

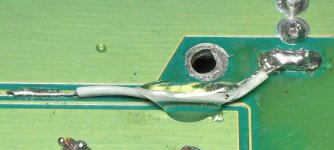

If this is a Rockford amp, you can do something similar to what's shown in the attached image.

Goop is my adhesive of choice. Both epoxy and super glue produce extremely irritating fumes if heated so never use them where you'll possibly have to solder in the future.

Goop is my adhesive of choice. Both epoxy and super glue produce extremely irritating fumes if heated so never use them where you'll possibly have to solder in the future.

Attachments

Perry Babin said:For short runs, resistor leads work well.

Wow, image in this post (Post #9) displays exactly an amp/part of board I am working at

Thanks a lot, Perry, for such detailed posts with pics!!! I really appreciate it and I think I am on a right track now

And, I already tried using Goop and like it a lot, it makes it nice and clean,I just wasn't been sure if it will work for this application.

I have that same kit.

I also use a 1100 dollar metcal iron with all the best re-work tips.

i would reccomend a good tip, no clean flux, solder. and a careful hand and a scope for shure.

it is really not all that bad if you can get the hang of it. shure beats soldering jumpers!!

I also use a 1100 dollar metcal iron with all the best re-work tips.

i would reccomend a good tip, no clean flux, solder. and a careful hand and a scope for shure.

it is really not all that bad if you can get the hang of it. shure beats soldering jumpers!!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- How to restore burnt/lifted traces?