I feel I'm not alone here but cooked subwoofer voice coil(s) appear to be the greatest cause of sub-woofer failure. Thinking on this a little... I asked myself why not throw a fuse on the hot lead in-between the amp and sub-woofer to prevent over current to the sub-woofer voice coils(s)? A condition, I feel is the #1 cause of voice coil cooking, assuming the sub-woofer voice coil is well made to begin with.

Sub woofers typically are rated in watts as follows. Some may contain only 2 ratings (peak & RMS)

Peak Power Handling: 4000 Watts

Program Power Handling: 2000 Watts

CEA Rated RMS Power Handling: 1000 Watts

So the question is knowing the watts and the voice coil(s) resistance, how would I caluate the fuse size and which rating would I use?

Sub woofers typically are rated in watts as follows. Some may contain only 2 ratings (peak & RMS)

Peak Power Handling: 4000 Watts

Program Power Handling: 2000 Watts

CEA Rated RMS Power Handling: 1000 Watts

So the question is knowing the watts and the voice coil(s) resistance, how would I caluate the fuse size and which rating would I use?

Last edited:

Just tossing out an example... Lest say we a dual 2 ohm voice coil subwoofer rated at 4000 watts peak, 2000 RMS and 1000 CEA rated RMS. So being conservative I want to fuse this for 1000 watts at 1 ohm (voice coils wired in parallel).

If I use this handy online calculator. I know the watts (1000) and the ohms (1). It's spits out

31.62 volts and 31.62 amps. So would I use a 30 amp fues then?

If I use this handy online calculator. I know the watts (1000) and the ohms (1). It's spits out

31.62 volts and 31.62 amps. So would I use a 30 amp fues then?

The main cause of voice coil burning is square waves from an over driven power amp. The speech coil sees them as DC and it can fry the coil.

A fuse is a good idea.

Use Ohms Law to calculate a realistic value.

P=I2 R so I = square root of P x R.

Use a semiconductor fast blow type.

A fuse is a good idea.

Use Ohms Law to calculate a realistic value.

P=I2 R so I = square root of P x R.

Use a semiconductor fast blow type.

The main cause of voice coil burning is square waves from an over driven power amp. The speech coil sees them as DC and it can fry the coil.

A fuse is a good idea.

Use Ohms Law to calculate a realistic value.

P=I2 R so I = square root of P x R.

Use a semiconductor fast blow type.

Thanks for the reply it's much appreciated.

My son gave me some old school no name 10" sub woofers from the early 90's, the just say made in USA and.nothing else. They are not all that beefy but if they lasted all this time so that's saying something...

Out of curiosity i put them in my sealed sub-woofer box and gave them a test run. I clamped my AC clamp meter to one of the positive leads to one of these single coil 4 ohm subwoofers. I had peak hold set on my meter while slowly turned up the volume to the point where I felt comfortable that I wouldn't burn the coils. My meter peaked @ 11.7 amps. If I understand ohms law correctly 11.7 amps through 4 ohms = 547.56 watts.

That's kind of crazy... because I wouldn't expect more than 400 watts out of these old subwoofers. I think I'll further my experiment with these sub-woofers and put a 10 amp automotive fuse on the positive leads, monitor again with my clamp meter and see what happens... Will the fuse blow @ over 10 amps or 400 watts? One would think it would but I'll see if it does.

Last edited:

Using an amp meter that's not sync'd to the voltmeter won't give an accurate reading for power.

Listen for clipping, listen for stress from the woofer. That's all that's needed to keep the woofers safe.

Thanks Perry for the reply and that makes sense! But in all honesty it's hard to listen for sub-woofer clipping and stress, when your consentrating on seeing and trying to keep your teeth from rattling loose... all while your itching your nose at the same time.

Would a positve lead fuse rated at CEA RMS, in-between the sub-woofer and amplifier be a good idea or not? My ideas aren't always the best ideas - that's for sure.

I'm envisioning an electronic circuit to sit in between the amplifier and subwoofer that had a LED ampmeter and a way to set the maximum wattage or amperage before it trips a re-setable breaker. I bet such a device would sell well, excpecially if it would also trip at amp overloading or detection of a squarewave coming from the amplifier. Think of it kind of like an electronic sub-woofer protection gaurdian. But it could also be used on other speakers and not just sub-woofers. So maybe it's more of a progamable speaker protection guardian or PSPG since acroynms are all the rage nowadays.

Last edited:

You used Peak Volts, then you calculated Peak WattsOut of curiosity i put them in my sealed sub-woofer box and gave them a test run. I clamped my AC clamp meter to one of the positive leads to one of these single coil 4 ohm subwoofers. I had peak hold set on my meter while slowly turned up the volume to the point where I felt comfortable that I wouldn't burn the coils. My meter peaked @ 11.7 amps. If I understand ohms law correctly 11.7 amps through 4 ohms = 547.56 watts.

So if you had measured that with a continuous sinewave you would actually have half peak=274W RMS.

but not even that, you measured widely separated random peaks, I bet *average* power was not more than 50 to 70W RMS.

Even worse, since you used peak *hold* you might have had a single 1 millisecond pulse in the enrire test ... and you wouldn´t know the diufference.

Nothing wrong with that, Music by its very nature is very dynamic, signal jumps up and down all the time.

Now if you had subjected your speakers to, say, 33V RMS continuous sinewave at some frequency inside their range, think from, say, 35Hz to 250Hz, meaning you feed them continuous 274W RMS ... I bet in an hour or two they might fry their voice coils or directly catch fire, go figure.

Well, you didn´t subject them to 540W RMS by any means,be certain of that.That's kind of crazy... because I wouldn't expect more than 400 watts out of these old subwoofers. I think I'll further my experiment with these sub-woofers and put a 10 amp automotive fuse on the positive leads, monitor again with my clamp meter and see what happens... Will the fuse blow @ over 10 amps or 400 watts? One would think it would but I'll see if it does.

Not even 400W , by far.

10A will not protect them because to begin with it won´t blow with 10A, go figure.

Fuse brating is the value where they will NEVER blow.

For the real one, get fuse datasheet, they list blowing time under different overload % ... you will be surprised.

Personally I use 80% to 60% calcukated current rating (so for your hypotethical 400W 4 ohm speaker I would use between 6 and 8 A , never 10 A) , feel adequately protected and hardly ever blow a fuse ... and then I take that as a strong indication tio turn volume down.

Last edited:

In 97 I purchased for my car 2x 12" Earthquake Magma's (dual 3.2ohm each, 500wrms) along with their 1st gen class D amp (200DHC) which was 1k RMS into 1ohm? or thereabouts! Amp is dual mono and internally combined I think so wiring was meant to be dual inputs at 1.6ohm each so amp reads 3+ internally? What the installer did was bridge to 0.5ohm which was a big no no as the community knows yet I still have the amp to this day running as well as the Magma subs which do home theatre duties now as I'm an old coont!

Anyway.....The subs either came with the fuse links or the installer used them with a 10amp fuse inline which I never managed to blow although SPL was never my intention. I did manage to blow 8amps easily through the various cars it was installed in over the ten years.

What I'm getting at is that it works and had done for me for years. Spade Fuses are cheap so go with the above recommendations but start lower amps and step up by 1's until you're happy with a size that will blow before blowing coils!

Anyway.....The subs either came with the fuse links or the installer used them with a 10amp fuse inline which I never managed to blow although SPL was never my intention. I did manage to blow 8amps easily through the various cars it was installed in over the ten years.

What I'm getting at is that it works and had done for me for years. Spade Fuses are cheap so go with the above recommendations but start lower amps and step up by 1's until you're happy with a size that will blow before blowing coils!

You used Peak Volts, then you calculated Peak Watts, not RMS.

So if you had measured that with a continuous sinewave you would actually have half peak=274W RMS.

but not even that, you measured widely separated random peaks, I bet *average* power was not more than 50 to 70W RMS.

Even worse, since you used peak *hold* you might have had a single 1 millisecond pulse in the enrire test ... and you wouldn´t know the diufference.

Nothing wrong with that, Music by its very nature is very dynamic, signal jumps up and down all the time.

Now if you had subjected your speakers to, say, 33V RMS continuous sinewave at some frequency inside their range, think from, say, 35Hz to 250Hz, meaning you feed them continuous 274W RMS ... I bet in an hour or two they might fry their voice coils or directly catch fire, go figure.

Well, you didn´t subject them to 540W RMS by any means,be certain of that.

Not even 400W , by far.

10A will not protect them because to begin with it won´t blow with 10A, go figure.

Fuse brating is the value where they will NEVER blow.

For the real one, get fuse datasheet, they list blowing time under different overload % ... you will be surprised.

Personally I use 80% to 60% calcukated current rating (so for your hypotethical 400W 4 ohm speaker I would use between 6 and 8 A , never 10 A) , feel adequately protected and hardly ever blow a fuse ... and then I take that as a strong indication tio turn volume down.

My AC clamp meter has a peak amperage hold option which is what I used. I didn't have it set to AC voltage. My intention was to measure peak AC amperage understanding that music is variable and most definitely not constant. But I really was surprised to see it hat peaked at 11.7 amps when I checked the meter. I was following Perry's advise listening to some indication the speakers (I only clamped 1 of the two) were under stress and clipping or distortion. I even felt the cones in between tracks for heat. They got a little warm but not hot.

Ok enough said - so if.i understand you correctly. I hit a peak of 547.56 watts for perhaps a brief second in time. As you said perhaps around 1/2 of that could have been program RMS 548 / 2 = 274 and then 1/2 of the program RMS is perhaps where the majority of the music was during the time. (274 / 2 = 137). Let's say I wanted to fuse this speaker for 400 watts knowing it has sussessfuly hit 547.56 for a breif second sussessfuly. is 400 watts a good WAG to protect the coils from frying during normal music playing (not a constant sign wave at lower amperage)?

Last edited:

In 97 I purchased for my car 2x 12" Earthquake Magma's (dual 3.2ohm each, 500wrms) along with their 1st gen class D amp (200DHC) which was 1k RMS into 1ohm? or thereabouts! Amp is dual mono and internally combined I think so wiring was meant to be dual inputs at 1.6ohm each so amp reads 3+ internally? What the installer did was bridge to 0.5ohm which was a big no no as the community knows yet I still have the amp to this day running as well as the Magma subs which do home theatre duties now as I'm an old coont!

Anyway.....The subs either came with the fuse links or the installer used them with a 10amp fuse inline which I never managed to blow although SPL was never my intention. I did manage to blow 8amps easily through the various cars it was installed in over the ten years.

What I'm getting at is that it works and had done for me for years. Spade Fuses are cheap so go with the above recommendations but start lower amps and step up by 1's until you're happy with a size that will blow before blowing coils!

Thanks +1 for old coonts - I'm one myself

I appreciate you taking time and explaining your setup and the fusable links - it's good to know it works and has for many years.

I may be a simplton, but just about everything comes with some type of electronic protection device but not speakers - why? Heck even my sawmill has popout breakers on every 12v motor circuit. It would seem to me that someone in the industry could come up with a similar protection device for speaker. Just think of how much warranty repairs/replacements a simple fusable link would solve. Excpecially if it were something similar to a popout breakers button that was intergated into the basket rim that you could reset (push in) from the front of the speaker. I mean amps is amps and coils are only good for so many amps. But in today's throw away world I'm probably talking crazy... Because very little if anything is made for longevity nowadays. They want it to break just after the warranty runs out so you buy another one.

Last edited:

I'm all for thinking about ways to do things 'right' but is there a right way to do this?

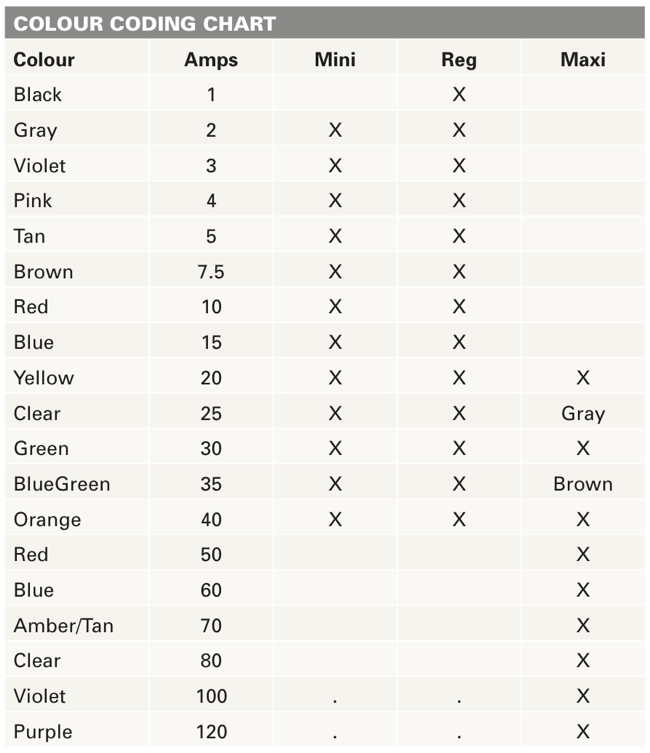

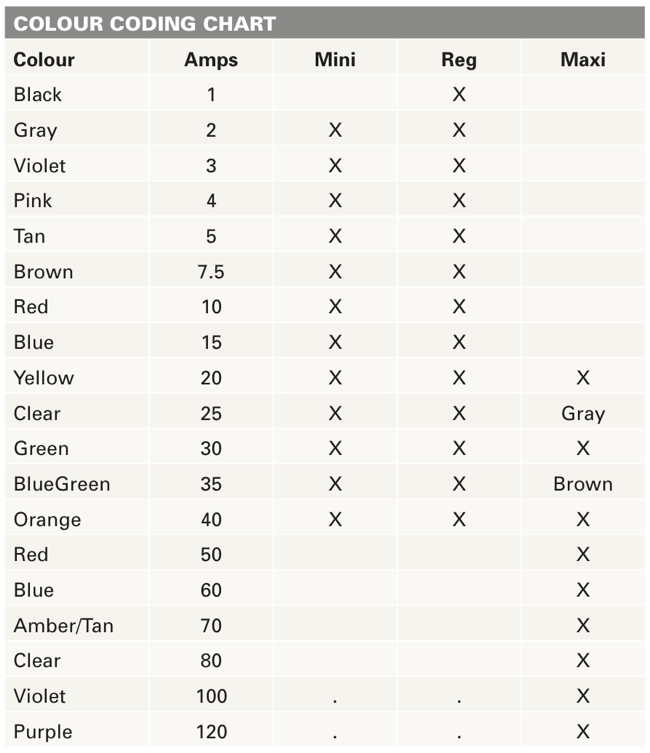

The fuse sizes above 10 amps are very far between.

If a 10 amp fuse blows and it blew at a level below where you want to listen to the system, will you simply keep the level low and replace the 10 amp fuse?

What if the voice coil fails with the 10 amp fuse? You don't really know what the voice coil can take unless you drive the speaker to failure.

The current through the voice coil isn't the same across the spectrum, even when driven with a sine sweep of a constant level. Add the reactance from the enclosure and you make the system more complex. If the enclosure is ported, you can easily destroy the woofer, physically if you drive it hard below the resonant frequency of the enclosure (remember, the mention of listening for stress?).

What about the fudging of power handling ratings by the manufacturers?

Again, you cannot use the clampmeter to determine power. The speaker has reactance which puts the voltage and current out of phase. This makes using a separate volt and amp meter virtually useless to measure power.

The fuse sizes above 10 amps are very far between.

If a 10 amp fuse blows and it blew at a level below where you want to listen to the system, will you simply keep the level low and replace the 10 amp fuse?

What if the voice coil fails with the 10 amp fuse? You don't really know what the voice coil can take unless you drive the speaker to failure.

The current through the voice coil isn't the same across the spectrum, even when driven with a sine sweep of a constant level. Add the reactance from the enclosure and you make the system more complex. If the enclosure is ported, you can easily destroy the woofer, physically if you drive it hard below the resonant frequency of the enclosure (remember, the mention of listening for stress?).

What about the fudging of power handling ratings by the manufacturers?

Again, you cannot use the clampmeter to determine power. The speaker has reactance which puts the voltage and current out of phase. This makes using a separate volt and amp meter virtually useless to measure power.

Here are the standard automotive blade fuse sizes and amperage ratings. I wished there were a few with ratings in-between 5 amps and 7.5 amps. I think I'll try both and see how it goes. 5 amps @ 4ohms = 100 watts, 7.5 amps @ 4 ohms = 225 watts. Anyways what's a few bucks for a little experiment that might just turn out to insurance. I'll let you all know how it goes. Thanks for all the replies

Attachments

to resurrect this thread - while working for Pioneer Electronics in the early 90s, the small Rockford Punch HD Series (45, 75, 150) had fused output leads.

The Pioneer engineers in Tokyo refused to put fuses onto their high current GMH amplifiers because it apparently plays havoc with some of the sonic output characteristics, including damping factor. This makes sense, as fusing output leads is really never been a thing, and it does add a small component of resistance etc into the output circuit. Also, not knowing the specific current and voltage curves is going to make this a hit or miss at best. Soft clipping, no bottoming and ensuring the subs are in the proper enclosure is likely the best bet. Having an amp that's twice the power output is also good medicine, as long as it doesn't clip hard or bottom out the speaker.

Funny story: When I was the distributor for Dr. Crankenstein subwoofers, I plugged one of their 12" HV series 4 ohm subs into the wall - 120v ac.......it blew the 15A breaker a pile of times and buzzed its way across the floor before finally dying about 10 minutes into this travesty. Should've installed it into an enclosure first, lol

The Pioneer engineers in Tokyo refused to put fuses onto their high current GMH amplifiers because it apparently plays havoc with some of the sonic output characteristics, including damping factor. This makes sense, as fusing output leads is really never been a thing, and it does add a small component of resistance etc into the output circuit. Also, not knowing the specific current and voltage curves is going to make this a hit or miss at best. Soft clipping, no bottoming and ensuring the subs are in the proper enclosure is likely the best bet. Having an amp that's twice the power output is also good medicine, as long as it doesn't clip hard or bottom out the speaker.

Funny story: When I was the distributor for Dr. Crankenstein subwoofers, I plugged one of their 12" HV series 4 ohm subs into the wall - 120v ac.......it blew the 15A breaker a pile of times and buzzed its way across the floor before finally dying about 10 minutes into this travesty. Should've installed it into an enclosure first, lol

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- Fuse between sub-woofer & amplifier?