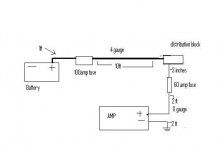

I have a ppi4100 which I have connected into 4 ohm loads, fronts are 100x2 rms and rear go to a sub, 400x1 rms. I've a attached a poorly drawn schematic of my how my system is wired.

So here is the problem. Sound sometimes cuts in and out. One day it cut completely out, so I looked at the amp and there was not any power to it, then I saw that my 60 amp fuse was in pieces, pics to be attached. The fuse never melted, but it looks like the wire started to melt on the side that goes to the the amp (looks black and burnt, the housing completely melted apart, and the fuse has some dark looking liq residue inside but still conducts.

Here are some of my ideas on what I think might be happening:

1. I recently repaired the amp, where a leg off the power inductor had broken off, since I could not solder it back to the board, I soldered a wire to the board and then the leg of the inductor to the wire. I haven't taken the amp apart yet to check, but maybe that wire is touching the heatsink occasionally, which kicks on the protection and my sound goes in and out, then it also causes a lot of current to flow which heats up the wire, but not enough to blow the fuse since it happens intermittently.

2. The 8 guage wire is too small, so wire heats up, and fuse doesn't blow. But then should the entire wire melt? Maybe as the housing starts to comeapart is the reason for the amp cutting in and out?

3. Similar logic to #1, but instead of inductor short, short is in speaker wiring is causing amp to cut in and out, and then leading to fuse housing failure.

would really like to figure out whats going on here. thanks!

So here is the problem. Sound sometimes cuts in and out. One day it cut completely out, so I looked at the amp and there was not any power to it, then I saw that my 60 amp fuse was in pieces, pics to be attached. The fuse never melted, but it looks like the wire started to melt on the side that goes to the the amp (looks black and burnt, the housing completely melted apart, and the fuse has some dark looking liq residue inside but still conducts.

Here are some of my ideas on what I think might be happening:

1. I recently repaired the amp, where a leg off the power inductor had broken off, since I could not solder it back to the board, I soldered a wire to the board and then the leg of the inductor to the wire. I haven't taken the amp apart yet to check, but maybe that wire is touching the heatsink occasionally, which kicks on the protection and my sound goes in and out, then it also causes a lot of current to flow which heats up the wire, but not enough to blow the fuse since it happens intermittently.

2. The 8 guage wire is too small, so wire heats up, and fuse doesn't blow. But then should the entire wire melt? Maybe as the housing starts to comeapart is the reason for the amp cutting in and out?

3. Similar logic to #1, but instead of inductor short, short is in speaker wiring is causing amp to cut in and out, and then leading to fuse housing failure.

would really like to figure out whats going on here. thanks!

Attachments

That amp draws WAY too much current for that fuse holder type. Use an anl wafer type fuse holder, WAY better. Those glass (agu) types can have a lot of resistance and build up heat, melting the solder loose inside the fuse. Then it can act like a circuit breaker and cut power off and on randomly. Also, I can't believe you are using an 8 gauge for that amp. Do it justice and use at least a 4 gauge, that thing needs voltage to give you clean wattage.

His amp is rated to run 800w rms when fully loaded. It would be drawing approximately 1500w through the fuse and wiring. He can not get that wattage through a tiny 8 gauge and a fuse holder with weak high resistance contacts. (maybe if the amp was only 15" from the battery, lol) They are going to phase that type of holder out anyway, because of the reliablility issues. The anl and mini anl (manl) never have those issues and only blow the fuse if the current drawn exceeds the fuse's rating. I haven't used an agu fuse holder since the early 90's. AGU FTL

Just to make things clear, I am running 4 gauge the length of the car, the 8 guage section is less than 2ft (from the distribution block to the amp), which, from what I have read, should be sufficient for the amount of current. Correct me if I'm wrong on that assumption.

I had this setup running since last october, no problems till June of this year, so granted that the fuse is faulty, what I need to figure out is whether the fuse itself was the cause of the 'cutting out' or did something else cause this, and its repercussions were seen in the fuse holder getting hot at its weakest point (highest resistance), which would be the connection point of the fuse holder to the wire.

Now to add to this saga, I connected another fuse and fuse holder. I just slipped some heat shrink over the end connectors, but I didn't have a heat gun available so it was 'un-shrunk.' I also used to look at it everyday. It was working fine for about two weeks. Then a couple days ago the 'cutting in and out' started again, I popped my trunk and looked at the fuse and saw that one end had 'shrunk,' as shown in the pic.

Unfortunately, I've never been able to look at the amp and catch it in the act of 'cutting in and out' so I don't know if it completely loses power (which would point to the fuse shorting out) or if the protection circuitry is engaging ( which would point to a short in the amp or in output wiring)

Since the 'cutting in and out' occured again, with and different fuse, fuse holder, and fully tightened screws, there must be something more going on.

I had this setup running since last october, no problems till June of this year, so granted that the fuse is faulty, what I need to figure out is whether the fuse itself was the cause of the 'cutting out' or did something else cause this, and its repercussions were seen in the fuse holder getting hot at its weakest point (highest resistance), which would be the connection point of the fuse holder to the wire.

Now to add to this saga, I connected another fuse and fuse holder. I just slipped some heat shrink over the end connectors, but I didn't have a heat gun available so it was 'un-shrunk.' I also used to look at it everyday. It was working fine for about two weeks. Then a couple days ago the 'cutting in and out' started again, I popped my trunk and looked at the fuse and saw that one end had 'shrunk,' as shown in the pic.

Unfortunately, I've never been able to look at the amp and catch it in the act of 'cutting in and out' so I don't know if it completely loses power (which would point to the fuse shorting out) or if the protection circuitry is engaging ( which would point to a short in the amp or in output wiring)

Since the 'cutting in and out' occured again, with and different fuse, fuse holder, and fully tightened screws, there must be something more going on.

Attachments

I agree, it shouldn't. Also the cutting in and out, occured at very low volume, if that helps any.

Just to get some knowledge thrown at me, I'll present a hypothetical situation:

If an amp was shorting out, due to internal short or output wiring, would a large enough amount of current flow in the power wires , after or whilst the protection circuitry is cutting the amp on and off?

Just to get some knowledge thrown at me, I'll present a hypothetical situation:

If an amp was shorting out, due to internal short or output wiring, would a large enough amount of current flow in the power wires , after or whilst the protection circuitry is cutting the amp on and off?

The problem is resistance. There's too much resistance at the fuse holder. When you draw current through a resistive point in a circuit, the point will heat up. High current will cause significant heating. If all of the components (fuse, holder, connection to wire...) were good quality, excessive current would simply blow the fuse.

You need to use a different type of fuse holder and/or a better quality fuse (only Bussmann or Littelfuse for this type of fuse). If you must use this type of fuse, use a high quality, open fuse holder. Gold plating doesn't make it high quality. Buy one from a high-end manufacturer. Maxi-fuses and ANL fuses have fewer problems.

ppia600 has a lot of experience with installation problems/solutions. You should take his advice.

The amp starts to cut out because the fuse holder begins to heat up, the connection deteriorates and the voltage at the amp begins to drop (due to increased resistance at the fuse holder). The deterioration is cumulative (any tiny resistance will soon become significantly more as you draw current through it).

You need to use a different type of fuse holder and/or a better quality fuse (only Bussmann or Littelfuse for this type of fuse). If you must use this type of fuse, use a high quality, open fuse holder. Gold plating doesn't make it high quality. Buy one from a high-end manufacturer. Maxi-fuses and ANL fuses have fewer problems.

ppia600 has a lot of experience with installation problems/solutions. You should take his advice.

The amp starts to cut out because the fuse holder begins to heat up, the connection deteriorates and the voltage at the amp begins to drop (due to increased resistance at the fuse holder). The deterioration is cumulative (any tiny resistance will soon become significantly more as you draw current through it).

Very good. I'll upgrade the fuse.

Now for running wire and fuse size, what are y'all's suggestions for that? Is the 8 gauge sufficient for the dist of the distribution block to the amp? If I did run the 4 gauge all the way to the amp, how can I connect it? 4 gauge won't fit in the connector.

thanks, appreciate all the input from everyone.

Now for running wire and fuse size, what are y'all's suggestions for that? Is the 8 gauge sufficient for the dist of the distribution block to the amp? If I did run the 4 gauge all the way to the amp, how can I connect it? 4 gauge won't fit in the connector.

thanks, appreciate all the input from everyone.

If a 60 amp fuse doesn't blow, the 8g may be enough. If the 60 amp fuse blows, you need larger wire.

After you get a good quality fuse/holder, check the temperature of the wire after running the amp at high volume for a while. If the wire doesn't feel warm (relative to the ambient temperature), it's OK. If the wire feels warm, it's too small and you should go to the next size.

You can buy 6g wire. People rarely use it because it's not readily available at car audio shops. You can get it from an automotive or welding supply house.

After you get a good quality fuse/holder, check the temperature of the wire after running the amp at high volume for a while. If the wire doesn't feel warm (relative to the ambient temperature), it's OK. If the wire feels warm, it's too small and you should go to the next size.

You can buy 6g wire. People rarely use it because it's not readily available at car audio shops. You can get it from an automotive or welding supply house.

I have seen that happen too. That kind of Chinese fuse holders tend to make poor contact with the fuse at both ends, as if they were sized to accomodate a slightly bigger one. Try narrowing the ends a bit so that the fuse becomes firlmy clamped. This should be more than enough for a 4x100 amplifier. You can even try 30A and it will hardly blow either.

I have also seen low quality Chinese fuses that either come completely open from the factory, or they have weak solder joints at both ends and become open later without the internal fuse element actually fusing (they are easily repaired by drilling a small hole at each end and soldering back the fuse element... It's a pity to throw away a brand new fuse...)

I have also seen low quality Chinese fuses that either come completely open from the factory, or they have weak solder joints at both ends and become open later without the internal fuse element actually fusing (they are easily repaired by drilling a small hole at each end and soldering back the fuse element... It's a pity to throw away a brand new fuse...)

Back in the day about all I could find was the flat auto fuses at 30A. They would heat a little (could barely feel it at full output) but then they or the holders would corrode and turn into a problem area. They would cut out and melt even though they were not getting hot from current; they got hot after they developed a bad connection. I finally figured out to fill a new one with dielectric grease and put a new fuse in it, never had problems with them after that. They were under hood in a dry area behind the battery, also had that issue in trunk. May not help other types of holders, but a little heat seems to exploit any weakness in a fuse holder not bolted together. I assume without air the metal can not oxidize so easily.

Are these bigger version of 20mm fuses that bad? My system has a 20A fuse and is just a 4x75 and 1x300 amp. Should I be dumping the fuse setup for ANL? I had a look and ANL fuse holders are £25 or £12 for cheap gold tacky looking ones. Not sure on the wire gauge but the outside diameter is no more than 10mm I would say, quite likely upto 2mm less.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- Fuse housing melting but fuse not blowing, ppi amp