I have this idea of bypassing a broken gain pot by removing it and using a resistor of approximately 50% of the pots range to permanently set the gain at 50%.

I would not mind changing the pot but I have never seen one like this (small green and 6 legged) if I could find a direct or equivalent replacement.

So is this a crazy idea or are the pots around?

I would not mind changing the pot but I have never seen one like this (small green and 6 legged) if I could find a direct or equivalent replacement.

So is this a crazy idea or are the pots around?

Sounds like a solid plan. Those pots all have low power ratings, you could use any 1/4 or 1/8 watt resistors in their place. I have searched for these multi-gang pots in the past without luck, maybe someone will come along and show us a source. That failing, you have a very reasonable approach and one that I am considering taking if I cannot clean a pot on an old MTX I have.

Regards,

David

Regards,

David

Johnny, the resistors will work fine as long as the center leg of the pot is electrically connected to one of the outer legs. They may be using the pot as an actual potentiometer, if this is the case you will need to use 2 resistors per each channel of the pot.

GT

To clean the pot on your MTX amp, try the following. You will have to remove the pot from the board. Go to a hardware store and buy a 1 inch pipe nipple 3 inches long. Get 3 PVC pipe caps. Drill a 3/16 inch hole in the center of one of the caps. Screw a pipe cap on one end of the nipple, drop the pot into the pipe, spray enough WD-40 into the pipe to cover the pot completely. Now screw the cap with a hole in it to the other end of the pipe.

Now using an air compressor and a blow nozzle, prefferably a blow nozzle with a rubber conical tip to make a good seal on the hole in the pipe cap. Pressurise the pipe several times. This will force the WD-40 into the pot. As soon as you remove the pot from the WD, you must turn it from stop to stop several times, this will use the wiper of the pot to clean the carbon on the control.

The third pipe cap is to seal the pipe and save the WD for your next project.

GT

To clean the pot on your MTX amp, try the following. You will have to remove the pot from the board. Go to a hardware store and buy a 1 inch pipe nipple 3 inches long. Get 3 PVC pipe caps. Drill a 3/16 inch hole in the center of one of the caps. Screw a pipe cap on one end of the nipple, drop the pot into the pipe, spray enough WD-40 into the pipe to cover the pot completely. Now screw the cap with a hole in it to the other end of the pipe.

Now using an air compressor and a blow nozzle, prefferably a blow nozzle with a rubber conical tip to make a good seal on the hole in the pipe cap. Pressurise the pipe several times. This will force the WD-40 into the pot. As soon as you remove the pot from the WD, you must turn it from stop to stop several times, this will use the wiper of the pot to clean the carbon on the control.

The third pipe cap is to seal the pipe and save the WD for your next project.

Attachments

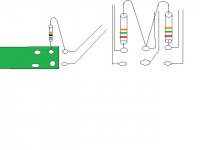

Do you know what value it is? Does it look like these.....

An externally hosted image should be here but it was not working when we last tested it.

Dont know what value......Do you know what value it is? Does it look like these

THey have markings on the side that say:

5038 (or 503"B")

HF

An externally hosted image should be here but it was not working when we last tested it.

another pic

An externally hosted image should be here but it was not working when we last tested it.

gtforme00 said:Could you post a more clear picture of the pin side of the board and the dimensions of the pot body?

Looking at the ALPS catalog, I found this model number: RK097122100Y

Dual gang, 50k, 3B taper (log taper)

Seems to match the specs, but I can't find it for sale.

The RK097122100Y has a switch. I don't see any 503B switchless pots in the RK097/98 series. It might be a custom job.

Just gotta dig a little at the japan site.

RK09712200FS

And mouser lists them, but they are non-stocked..

Alps catalog page with part ->

http://www3.alps.com/WebObjects/catalog.woa/E/PDF/Potentiometer/MetalShaft/RK097/RK097.PDF

Good luck!

- Matt

RK09712200FS

And mouser lists them, but they are non-stocked..

Alps catalog page with part ->

http://www3.alps.com/WebObjects/catalog.woa/E/PDF/Potentiometer/MetalShaft/RK097/RK097.PDF

Good luck!

- Matt

MatthewS said:Just gotta dig a little at the japan site.

RK09712200FS

And mouser lists them, but they are non-stocked..

Alps catalog page with part ->

http://www3.alps.com/WebObjects/catalog.woa/E/PDF/Potentiometer/MetalShaft/RK097/RK097.PDF

Good luck!

- Matt

That is indeed 50K without a switch, but it is 15A taper not 3B.

Using the resistors as shown will work for most amps. Using two equal value resistors won't be equal to the center gain position if the pot had a log taper (but it will work).

The MTX gain pot may be different (see attached). I know it is on some of their sub amps. The attached image is for a single channel.

The MTX gain pot may be different (see attached). I know it is on some of their sub amps. The attached image is for a single channel.

Attachments

Perry,

Thank you for answering that question. I had wondered myself whether two equal resistors would give a center gain position.

Looking at the Alps datasheet, it looks as if the linear and 3B (which is not log btw) tapers do intersect at 50% of the rotation, so I was under the impression that the gains would match at and only at 50% of the rotation, meaning that for the case of 50% gain two equal resistors would work.

If this has not been your observation, I defer to your experience.

Thank you also for the MTX gain pot schematic. I will attempt to clean the pot as described above, and failing all attempts to clean, will hard wire the resistors as you described.

Regards,

David

Thank you for answering that question. I had wondered myself whether two equal resistors would give a center gain position.

Looking at the Alps datasheet, it looks as if the linear and 3B (which is not log btw) tapers do intersect at 50% of the rotation, so I was under the impression that the gains would match at and only at 50% of the rotation, meaning that for the case of 50% gain two equal resistors would work.

If this has not been your observation, I defer to your experience.

Thank you also for the MTX gain pot schematic. I will attempt to clean the pot as described above, and failing all attempts to clean, will hard wire the resistors as you described.

Regards,

David

Attachments

WD-40????

I have used the stuff for years but I honestly dont know what I feel about using it to clean pots. Take into consideration that I am green. It would seems to me that its oily and highly flammable nature (not to mention that I think its conductive) would not imo be a good choice to clean pots.

If I needed to clean a pot I think I would use a quick flashing non conductive contact cleaner.

I have been surprised by a lot of thing that I would have swore would not work

I have used the stuff for years but I honestly dont know what I feel about using it to clean pots. Take into consideration that I am green. It would seems to me that its oily and highly flammable nature (not to mention that I think its conductive) would not imo be a good choice to clean pots.

If I needed to clean a pot I think I would use a quick flashing non conductive contact cleaner.

I have been surprised by a lot of thing that I would have swore would not work

gtforme00:

If your MTX amp uses the same type of pot, you'd short center to outside legs and use a resistor from the center to the other leg for each section. I'm not sure how the amp would react to using two equal value resistors per section.

Jonny Hotnuts:

WD-40 works better than most contact cleaners that leave no residue. There are a few instances where I wouldn't use it but it's OK for virtually all car audio amps. I learned this from a TV tech that used it for ~40 years. If you use a contact cleaner that leaves no residue, the pot is likely to become noisy again within a few days/weeks.

If you want to use something that is made for pots, use DeoxIt D5 to clean and DeoxIt S5 to protect the pot long term.

If you have plastic pots like those shown, they are sometimes sensitive to heat so try cleaning them without removing them. If you insert a razor knife blade in between the sections of the pot (opposite the side with the rivet), you can separate the halves just slightly to allow the cleaner to get into the pot. Do this on the corner and don't insert the blade more than 1/32 of an inch.

If you want to prevent damaging the pot, use a low temp solder alloy (ChipQuik) and an iron with an adjustable temp. Set the iron to ~450F and apply the alloy to the solder connections. Heat all legs at once and pull the pot.

If the pot is extremely noisy when the shaft is moved up or down, the pot is probably beyond repair. They rivets that keep pressure between the leg and the resistive element get loose and there's no practical way to tighten them.

If your MTX amp uses the same type of pot, you'd short center to outside legs and use a resistor from the center to the other leg for each section. I'm not sure how the amp would react to using two equal value resistors per section.

Jonny Hotnuts:

WD-40 works better than most contact cleaners that leave no residue. There are a few instances where I wouldn't use it but it's OK for virtually all car audio amps. I learned this from a TV tech that used it for ~40 years. If you use a contact cleaner that leaves no residue, the pot is likely to become noisy again within a few days/weeks.

If you want to use something that is made for pots, use DeoxIt D5 to clean and DeoxIt S5 to protect the pot long term.

If you have plastic pots like those shown, they are sometimes sensitive to heat so try cleaning them without removing them. If you insert a razor knife blade in between the sections of the pot (opposite the side with the rivet), you can separate the halves just slightly to allow the cleaner to get into the pot. Do this on the corner and don't insert the blade more than 1/32 of an inch.

If you want to prevent damaging the pot, use a low temp solder alloy (ChipQuik) and an iron with an adjustable temp. Set the iron to ~450F and apply the alloy to the solder connections. Heat all legs at once and pull the pot.

If the pot is extremely noisy when the shaft is moved up or down, the pot is probably beyond repair. They rivets that keep pressure between the leg and the resistive element get loose and there's no practical way to tighten them.

Wow, thanks PB....learn something new everyday.

I thought WD was only good for race cars!

The pot in question was over-turned (not by me). The pot is not noisy it just doesn’t work (you can wiggle the shaft and get random jumps in volume) and turns infinitely while the adjacent pot turns about 360 degrees and stops.

What would be the big deal if I were to install a pot with the same pin config and a different taper, or different K (assuming I did it with both channels)?

I don’t care if it would not accept line level in or if I had to drive the amp a bit harder with a pre. This seems like a good way to go, and I dont think a like pin configuration would be hard to find.

-JH

I thought WD was only good for race cars!

The pot in question was over-turned (not by me). The pot is not noisy it just doesn’t work (you can wiggle the shaft and get random jumps in volume) and turns infinitely while the adjacent pot turns about 360 degrees and stops.

What would be the big deal if I were to install a pot with the same pin config and a different taper, or different K (assuming I did it with both channels)?

I don’t care if it would not accept line level in or if I had to drive the amp a bit harder with a pre. This seems like a good way to go, and I dont think a like pin configuration would be hard to find.

-JH

A different taper wouldn't cause any problems.

Generally, with a linear taper the level would increase at a faster rate at low gain. At higher gain, there would be very little change for a given amount of rotation (compared to what you'd see at low gain levels). You see this on a lot of computer software (media players). They use the wrong taper for the volume control.

Most pots rotate ~270°. The only reason I mention this is because I don't want you to waste time looking for a pot that rotates 360°.

When the pot is rotated too far, the wiper is typically destroyed. From that point on, the wiper digs into the resistive element and there's no saving it. This is more common on larger, metal frramed pots but it can happen to any pot.

Is this an amp from a Japanese manufacturer? If so, you may be able to get the OEM part.

Does this amp have individual gains for each channel?

Generally, with a linear taper the level would increase at a faster rate at low gain. At higher gain, there would be very little change for a given amount of rotation (compared to what you'd see at low gain levels). You see this on a lot of computer software (media players). They use the wrong taper for the volume control.

Most pots rotate ~270°. The only reason I mention this is because I don't want you to waste time looking for a pot that rotates 360°.

When the pot is rotated too far, the wiper is typically destroyed. From that point on, the wiper digs into the resistive element and there's no saving it. This is more common on larger, metal frramed pots but it can happen to any pot.

Is this an amp from a Japanese manufacturer? If so, you may be able to get the OEM part.

Does this amp have individual gains for each channel?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- Bypassing broken gain pots