Yes, the 1000u BG STD caps are mounted on rectifier board as seen here: http://www.diyaudio.com/forums/showthread.php?postid=867612#post867612 They don't go exactly into place of 4.7 caps as my new boards hve additional holes to accomodate those bigger caps.

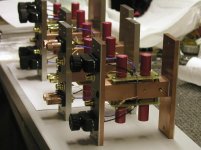

Here some pics how the Patek is made.

Here some pics how the Patek is made.

Attachments

With regards to amp alone, the difference between regular version and SE becomes very small now.

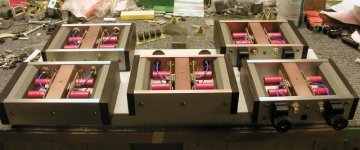

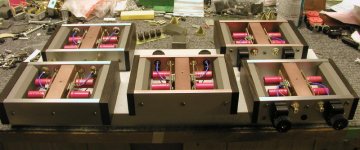

In a pic below you see both versions, the only difference are copper/aluminum panels for SE, while regular amp features aluminum only.

The main difference is for PS enclosure.

In a pic below you see both versions, the only difference are copper/aluminum panels for SE, while regular amp features aluminum only.

The main difference is for PS enclosure.

Attachments

-=Zepplock=- said:How much? ;-)

One of a kind chassis, especially when hand build (like pictured above) are very time consuming and as such are not offered widely. If I'm asked to build something like that on special request, I'm asking at least $350 (chassis only) and it's still not much appealing to me. That's why I rather prefer to show a way how to build it, than actually building it

Presently, only one chassis is being offered, the Integrated Amp chassis. It will become available soon at $250/ set.

It's perfectly fine. The difference is due to mains voltage fluctuation (check what voltage is on primaries side) and also, this is 50W transformer, which means it is rated 8V at full current draw, which never actually occurs with that DAC circuit.

The real life secondary voltage is about right for the onboard regulators.

The real life secondary voltage is about right for the onboard regulators.

edjosh23 said:I purchased a Freud non-ferrous blade a couple weeks ago for about $45. I finally got to use it this weekend, my first time cutting metal, and WOW! It worked out really well. I have very few tools, but the cuts I made with it were amazing, or atleast for an amatuer like myself.

With a proper blade, cutting aluminum is not much different from cutting wood. If you want to achieve better looking cuts, move the piece really slow. I recently bought 100 teeth blade and I'm amazed with a finish of the cut: it looks almost as if it was milled.

The DAC info was posted here: http://www.diyaudio.com/forums/showthread.php?postid=609968#post609968

I just cut a piece of 0.400 aluminum, this is how it looks:

I just cut a piece of 0.400 aluminum, this is how it looks:

Attachments

Thanks,

I must have missed that page.

I tried to take a picture of one of my cuts, but my camera is dead. I put the batteries in the camera on Sunday, and took about 7 or 8 pictures, suddenly the batteries are all drained. Now the USB can no longer power the camera either. Time for a new camera. This time I'll be sure to pick out a camera that can take close up pictures.

Thanks,

Josh

I must have missed that page.

I tried to take a picture of one of my cuts, but my camera is dead. I put the batteries in the camera on Sunday, and took about 7 or 8 pictures, suddenly the batteries are all drained. Now the USB can no longer power the camera either. Time for a new camera. This time I'll be sure to pick out a camera that can take close up pictures.

Thanks,

Josh

sorry if this isn't the place for workshop advice but I thought I'd add my experience.

After a few DIYers had said aluminium cutting was not difficult, I bought myself an aluminium blade cheap(ish) on eBay, which may have been the mistake, and with a bit of trepidation I set out to cut up my 10mm aluminum sheet.

From the start it didn't feel good. One of the teeth kept not clearing itself so I had to keep stopping to pull the swarf out with pliers. After a while that tooth broke off and a different one became the 'collector'.

Needles to say the cut edges will need a lot of sanding.

My aluminum is 6082 T6 which from memory is the high strength grade, so the problem could be a mixture of that or a low quality blade, or something else.

After a few DIYers had said aluminium cutting was not difficult, I bought myself an aluminium blade cheap(ish) on eBay, which may have been the mistake, and with a bit of trepidation I set out to cut up my 10mm aluminum sheet.

From the start it didn't feel good. One of the teeth kept not clearing itself so I had to keep stopping to pull the swarf out with pliers. After a while that tooth broke off and a different one became the 'collector'.

Needles to say the cut edges will need a lot of sanding.

My aluminum is 6082 T6 which from memory is the high strength grade, so the problem could be a mixture of that or a low quality blade, or something else.

That was definately the blade. There is no reason a carbide blade should load up, unless it is dull or mis-aligned. With missing teeth cutting metal with a table saw becomes increasingly dangerous. The odds of the material grabbing and kicking back increase dramatically. Don't ask me how I know

DaveM

DaveM

aluminium finisher

I've tried to locate the Alodine that you mentioned in a very early thread, to add a finish to my PDA30 amp. In the UK it's "out of stock" bl**dy expensive and the product spec says it gives a golden yellow finish.

I've found Aluma-Dyne E-2300 which it says gives a clear finish. Do you think this is "close enough for Jazz". Interestingly both products are used in the aero industry. http://www.aircraftcoverings.co.uk/main.htm /product catalogue/ conversion coatings; about halfway down the page

Thanks

Kev

I've tried to locate the Alodine that you mentioned in a very early thread, to add a finish to my PDA30 amp. In the UK it's "out of stock" bl**dy expensive and the product spec says it gives a golden yellow finish.

I've found Aluma-Dyne E-2300 which it says gives a clear finish. Do you think this is "close enough for Jazz". Interestingly both products are used in the aero industry. http://www.aircraftcoverings.co.uk/main.htm /product catalogue/ conversion coatings; about halfway down the page

Thanks

Kev

Peter,

looking at the production images of your amps rose up a few questions (I did not find an answer in this long thread):

1. How do you mount the chip on the other side of the PCB? Is there not any interference from the solder of the resistors, and how is the pressure maintained to clamp the chip the the heatsink metal?

2. You seem to use only caddocks. No Rikens anymore? And where is the feedback resistor, because there seems to be no more space on the other side?

Klaus

ps: After using the DAC now for a longer period with pleasure, I want to make my Ref Amp also a bit like yours: Can you supply the necessary 2 x 100µF NX (NX) and 2x1000µF Blackgates?

looking at the production images of your amps rose up a few questions (I did not find an answer in this long thread):

1. How do you mount the chip on the other side of the PCB? Is there not any interference from the solder of the resistors, and how is the pressure maintained to clamp the chip the the heatsink metal?

2. You seem to use only caddocks. No Rikens anymore? And where is the feedback resistor, because there seems to be no more space on the other side?

Klaus

ps: After using the DAC now for a longer period with pleasure, I want to make my Ref Amp also a bit like yours: Can you supply the necessary 2 x 100µF NX (NX) and 2x1000µF Blackgates?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Audio Sector

- AudioSector-chip amp kits, dacs, chassis