Thanks, but I'm actually looking for something with the holes included. Sorry!

Aengus said:Hi

Just saw this thread - is this of any use to you?

Aengus

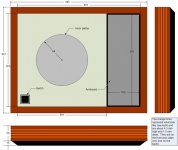

Linn LP 12 Diagram

Here is the PDF with the measurements for the LP 12 topplate.

Sorry about the delay, but easter and 3 days of rock festival takes its toll when you behave like you're 25 and forget that you're 46. (As I said to my friend Mick, we should never have smoked that last spliff. Anyway it was good fun and I think it is very important to hear live music. ( I'm so lucky beeing married to a classical violinist, so I hear most of her gigs, like The Australian Brandenburg etc. for free)

The drawing is the Linn LP12 top plate as seen from underneath. The plate is 1.5mm stainless. All measurements are in millimeter with the holes grey and the diameter in red text. All measurements are done with a caliper and a steel ruler, and should be within +/- 0.1 mm ( Take into account that this is seen with 46 year old eyes). The only critical positions are the three holes that holds the suspension. The two holes with in blue have a tread that seems to be UNF and slightly smaller than 3mm (Metric). These holes

are for the vertical angle adjustment of the motor, so I guess two 3mm hex (Unbraco) screws will do the job.

There are a few good websites for Linn LP 12 like www.sondek-turntable.com and www.originlive.com.

In addition, I have the setup manual as a word doc, so tell me if you need a copy.

Good luck and all the best.

Ketil

Here is the PDF with the measurements for the LP 12 topplate.

Sorry about the delay, but easter and 3 days of rock festival takes its toll when you behave like you're 25 and forget that you're 46. (As I said to my friend Mick, we should never have smoked that last spliff. Anyway it was good fun and I think it is very important to hear live music. ( I'm so lucky beeing married to a classical violinist, so I hear most of her gigs, like The Australian Brandenburg etc. for free)

The drawing is the Linn LP12 top plate as seen from underneath. The plate is 1.5mm stainless. All measurements are in millimeter with the holes grey and the diameter in red text. All measurements are done with a caliper and a steel ruler, and should be within +/- 0.1 mm ( Take into account that this is seen with 46 year old eyes). The only critical positions are the three holes that holds the suspension. The two holes with in blue have a tread that seems to be UNF and slightly smaller than 3mm (Metric). These holes

are for the vertical angle adjustment of the motor, so I guess two 3mm hex (Unbraco) screws will do the job.

There are a few good websites for Linn LP 12 like www.sondek-turntable.com and www.originlive.com.

In addition, I have the setup manual as a word doc, so tell me if you need a copy.

Good luck and all the best.

Ketil

Attachments

UNF

Hi J.C.

UNF is as far as I know an American standard for tread on nuts and bolts.

UNC is the coarse tread and UNF is the fine.

The file is made by a program called Corel Draw. v.12. and it can export PDFs. Apart from the program, some time, a ruler, a caliper and reading glasses in addition to a Linn top plate that has been living in boxes since 1985 (Thats when I gutted and rebuildt my Linn).

Cheers

Ketil

Hi J.C.

UNF is as far as I know an American standard for tread on nuts and bolts.

UNC is the coarse tread and UNF is the fine.

The file is made by a program called Corel Draw. v.12. and it can export PDFs. Apart from the program, some time, a ruler, a caliper and reading glasses in addition to a Linn top plate that has been living in boxes since 1985 (Thats when I gutted and rebuildt my Linn).

Cheers

Ketil

Image files

Hi

Corel can export to lots of graphical file formats. JPG, GIF, TIFF etc. in addition to vector files like DFX, AI (Illustrator) etc. If you want to edit the drawing, it's best to use a program that can do vectors (Corel, Illustrator, Autocad etc.).

I can send the original Corel file or any other vector format (within Corels export range) you need to your email.

Cheers

Ketil

Hi

Corel can export to lots of graphical file formats. JPG, GIF, TIFF etc. in addition to vector files like DFX, AI (Illustrator) etc. If you want to edit the drawing, it's best to use a program that can do vectors (Corel, Illustrator, Autocad etc.).

I can send the original Corel file or any other vector format (within Corels export range) you need to your email.

Cheers

Ketil

Linn LP12 Top Plate

While this is an old posting, there have been a number of companies (Linn Included) that have introduced various sub-chassis, top-plate and arm-board modifications for the LP12 in recent times.

I have recently stripped down my LP12 and can't help but feel that some of the problems with trying to get a good bounce during set-up comes from the fact that the top-plate is bowed and, the suspension bolts are not always 100% vertical as a result. I have studied many set-up documents and some of these guides talk about "Straightening the Bolts" during setup. In fact, Linn go so far as to make a tool to do this very task. In reality, not only are the bolts bent to a vertical position but, the top plate is further distorted at the bolt head in an effort to solve the issue of the top-plate not being true.

I understand that Linn claim that the top-plate is deliberately bowed during manufacture to eliminate resonances and wonder if the top-plate is actually distorted while the holes are being pressed / machined during manufacture (maybe the curve comes from the rolled stainless stock). I am pretty sure that the Linn Brigade will vociferously and feverishly defend the "purity" of the LP12 and it is not my intent to enter into any lengthy debate on the LP12's design. In fact, I like the sound of my LP12 in many respects and although I now prefer the sound of my Garrard 301, I wish to continue tinkering with the Linn but only in a DIY fashion.

Has anyone out there tried different top plate materials? (Aluminum, Acrylic, Carbon Fibre, Wood?? etc and has this worked to improve the sound quality ease of set-up - Is the bowed top plate really a necessity?

While this is an old posting, there have been a number of companies (Linn Included) that have introduced various sub-chassis, top-plate and arm-board modifications for the LP12 in recent times.

I have recently stripped down my LP12 and can't help but feel that some of the problems with trying to get a good bounce during set-up comes from the fact that the top-plate is bowed and, the suspension bolts are not always 100% vertical as a result. I have studied many set-up documents and some of these guides talk about "Straightening the Bolts" during setup. In fact, Linn go so far as to make a tool to do this very task. In reality, not only are the bolts bent to a vertical position but, the top plate is further distorted at the bolt head in an effort to solve the issue of the top-plate not being true.

I understand that Linn claim that the top-plate is deliberately bowed during manufacture to eliminate resonances and wonder if the top-plate is actually distorted while the holes are being pressed / machined during manufacture (maybe the curve comes from the rolled stainless stock). I am pretty sure that the Linn Brigade will vociferously and feverishly defend the "purity" of the LP12 and it is not my intent to enter into any lengthy debate on the LP12's design. In fact, I like the sound of my LP12 in many respects and although I now prefer the sound of my Garrard 301, I wish to continue tinkering with the Linn but only in a DIY fashion.

Has anyone out there tried different top plate materials? (Aluminum, Acrylic, Carbon Fibre, Wood?? etc and has this worked to improve the sound quality ease of set-up - Is the bowed top plate really a necessity?

Seen the uploaded pdf file here, and its all in metric.

Recently, out of curiosity, I did some measurements on my own top plate and found they easily match rounded up figures in Imperial measurement which I'm confident they would have used from the very beginning. The measurements have not changed AFAIK. Only the main suspension bolts are seen to be metric. Motor screws went metric a bit later on.

Recently, out of curiosity, I did some measurements on my own top plate and found they easily match rounded up figures in Imperial measurement which I'm confident they would have used from the very beginning. The measurements have not changed AFAIK. Only the main suspension bolts are seen to be metric. Motor screws went metric a bit later on.

Last edited:

I understand that Linn claim that the top-plate is deliberately bowed during manufacture to eliminate resonances and wonder if the top-plate is actually distorted while the holes are being pressed / machined during manufacture (maybe the curve comes from the rolled stainless stock). I am pretty sure that the Linn Brigade will vociferously and feverishly defend the "purity" of the LP12 and it is not my intent to enter into any lengthy debate on the LP12's design. In fact, I like the sound of my LP12 in many respects and although I now prefer the sound of my Garrard 301, I wish to continue tinkering with the Linn but only in a DIY fashion.

The top plate was deliberately bowed in a vain attempt to reduce vibrations, mainly from the motor. It was only somewhat successful, hence the addition of the "corner bolt mod" where the motor is.

I also like to tinker with my LP12, it's taken me years to get it to sound decent. It's my reference for now, but will eventually give way to something better. Some of the mods I've done are; top plate flip, so that the motor is at approx. 7:30. Stock sub-chassis has been treated with anti-vibration compound. Baltic Birch arm-board with Jelco 370H, replacing the original crappy Akito I. Hercules II motor drive mounted in an external box. Future mods include; DIY Sole sub-chassis with custom bearing and some mods to the top plate.

Has anyone out there tried different top plate materials? (Aluminum, Acrylic, Carbon Fibre, Wood?? etc and has this worked to improve the sound quality ease of set-up - Is the bowed top plate really a necessity?

Someone in Gr. Britain has recently introduced a very nice machined aluminum top plate. Don't recall the name, but saw it posted on the PFM forum.

jeff

Its called the Khan -three part system.

Tiger-Paw - Products

Very nice and I think its gaining acceptance, but there's a price to it.

Tiger-Paw - Products

Very nice and I think its gaining acceptance, but there's a price to it.

LP12s suck

mainly (perhaps) because I don't own one.

However, I am making an LP12-"ish" TT. Wood top plate (BB ply), wood armboard/subchassis, new plinth, multiple aluminum cross braces. Maple (solid) plinth, linear rubber suspension, DIY mat, Linn AkitoII (which is a very good arm) or my 219 arm.Platter and bearing from a Sugden BD2, motor from whatever I can get my grubby hands on.

If I end up doing a new metal top plate it will be thick aluminum milled similarly to the Tiger Paw Khan, but more massive. Or else thick stainless (thick enough to not require any additional support or corner bolt mods).

mainly (perhaps) because I don't own one.

However, I am making an LP12-"ish" TT. Wood top plate (BB ply), wood armboard/subchassis, new plinth, multiple aluminum cross braces. Maple (solid) plinth, linear rubber suspension, DIY mat, Linn AkitoII (which is a very good arm) or my 219 arm.Platter and bearing from a Sugden BD2, motor from whatever I can get my grubby hands on.

If I end up doing a new metal top plate it will be thick aluminum milled similarly to the Tiger Paw Khan, but more massive. Or else thick stainless (thick enough to not require any additional support or corner bolt mods).

If I end up doing a new metal top plate it will be thick aluminum milled similarly to the Tiger Paw Khan, but more massive. Or else thick stainless (thick enough to not require any additional support or corner bolt mods).

Actually, the stock top plate would be fine if it was properly supported, and damped around the motor location. Unfortunately, Linn decided not to bother.

Same with the stock steel sub-chassis, it rings like a bell. This is the main reason there are so many aftermarket choices available. All are substantially cheaper than the Keel, which is absurdly overpriced.

jeff

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Anyone have a diagram of the Linn top plate?