... a lot of work.

That's why we're all waiting for you to do it.

Regards.

Aengus

Hi All,

I've only read the first ten pages of this thread so far, but I'd like to add a note that I own an older (circa: 1970-1975) belt drive, aluminum platter turntable on a plastic base (Not a really expensive or high end BDTT) from a maker who has been in the business for thirty or forty years now.

This 1970's BDTT has a dual ring magnet bearing under the fairly light weight aluminum platter. The ring magnets OD are approximately the size of an LP's record label and ID about 1 inch smaller. While I've never measured it, I guess the platter is suspended some 2 - 4 mm to unload the center bearing when a rubber mat and LP are in place.

-Steven L. Bender, Designer of Vintage Audio Equipment

I've only read the first ten pages of this thread so far, but I'd like to add a note that I own an older (circa: 1970-1975) belt drive, aluminum platter turntable on a plastic base (Not a really expensive or high end BDTT) from a maker who has been in the business for thirty or forty years now.

This 1970's BDTT has a dual ring magnet bearing under the fairly light weight aluminum platter. The ring magnets OD are approximately the size of an LP's record label and ID about 1 inch smaller. While I've never measured it, I guess the platter is suspended some 2 - 4 mm to unload the center bearing when a rubber mat and LP are in place.

-Steven L. Bender, Designer of Vintage Audio Equipment

YNWOAN Said in 2007 -

I notice in this months Hi-Fi+ that Clearaudio have produced a turntable using a similiar (in concept, but different in detail) bearing. I was not at all aware that any 'reasonably' priced turntable had employed this principal. The bearing experiments are only a small element of a much larger project to engineer a whole turntable. I have already done this a couple of times but am intending to approach this new design from first principles. Like Clearaudio I intend to use a low mass acrylic platter (lower than Clearaudio though), although every other aspect will be quite different. I notice that Clearaudio have used a ceramic bearing shaft to stop it from conducting the magnetic field. The bearing in my current design (Linn main bearing) does indeed conduct the magnetic field generated by my magnetic bearing, but I believe this to be irelevant to performance - leakage from the spindle is very low and has no measurable effect on the cartridge that I am aware of. I am pleased however, that Hi-Fi+ seem to hear very much the same improvements I reported.

Successful Mag Lev on a Linn Sondek LP12...Wolf in sheep's clothing...

Magnets....Sheffield...Magnets...Sheffield...

I read all the posts on this thread with great interest last night for a couple of hours....after I had looked up 'magnetic turntable bearing' on google...

Three things amaze me.

Firstly, I am very impressed with everybody's interest in the subject....I had thought I was alone!

Secondly, yesterday, after a few weeks of experimenting, I had managed to use mag lev on a Linn Sondek LP12, which, although it is alternately cast as an angel or a villain in the world of hifi, certainly has, in its natural form, a really musical toe tapping ability. For a few months now, a) because I am on a budget, and b) because I have engineering skills and can't ever leave well alone, I have been rebuilding my LP12 with:

1. a CAD designed water-cut single piece titanium subchassis & arm mount,

2. a CAD redesigned thicker water-cut stainless steel top plate,

3. new 7pm motor position,

4. new external & internal electronics,

5. thicker & more rigid higher tensile steel bolt & locknut components,

6. machined corian armboard,

7. machined corian baseplate,

8. lathe turned dural thickened bearing housing,

9. silicon or rubber rings on crucial parts to damp resonances,

10. molybdenum sulphide greased ruby motor bearing in phosphor bronze bearing housing,

11. laser cut and hand finished acetyl arm pillar mounted cradle for the armrest,

12. thick water-cut stainless steel motor mounting,

13. two-part mag lev ring bearing on main bearing, relieving thrust plate pressure and consequent reduction of friction & noise,

14. solid silver wiring throughout,

15. renovation of rosewood plinth,

16. rebuilding of internal hidden elements of plinth (eg internal mahogany top-plate supports)

17. other minor aspects....polishing of bearing shaft tip, etc...

and it is sounding SO good.....

Thirdly, when reading the thread, I notice that a few of you had talked about living in the UK, in Sheffield, in S11 or S7.

When I was a young guy, I remember Sheffield was world-famous for its steel works and I remember drinking Magnet ale...in fact the famous Sheffield United football team fans' song refers to 'Magnet' ale produced locally by John Smith's Brewery, a packet of Woodbines cigarettes, a pinch of snuff(tobacco), a night out in Sheffield and a greasy chip butty.

The full lyrics to Sheffield United's Greasy Chip Butty song are:

You fill up my senses Like a gallon of Magnet

Like packet of Woodbines

Like a good pinch of snuff

Like night out in Sheffield

Like a greasy chip butty

Like Sheffield United Come thrill me again....

Na Na Naa Naa Naaaaa, Oooooooh!"

Recognise it?

Well the thing is...

I was born in Sheffield S11 too...and lived there until I was 17....

There MUST have been something in the water....

Magnets....Sheffield...Magnets...Sheffield...

I read all the posts on this thread with great interest last night for a couple of hours....after I had looked up 'magnetic turntable bearing' on google...

Three things amaze me.

Firstly, I am very impressed with everybody's interest in the subject....I had thought I was alone!

Secondly, yesterday, after a few weeks of experimenting, I had managed to use mag lev on a Linn Sondek LP12, which, although it is alternately cast as an angel or a villain in the world of hifi, certainly has, in its natural form, a really musical toe tapping ability. For a few months now, a) because I am on a budget, and b) because I have engineering skills and can't ever leave well alone, I have been rebuilding my LP12 with:

1. a CAD designed water-cut single piece titanium subchassis & arm mount,

2. a CAD redesigned thicker water-cut stainless steel top plate,

3. new 7pm motor position,

4. new external & internal electronics,

5. thicker & more rigid higher tensile steel bolt & locknut components,

6. machined corian armboard,

7. machined corian baseplate,

8. lathe turned dural thickened bearing housing,

9. silicon or rubber rings on crucial parts to damp resonances,

10. molybdenum sulphide greased ruby motor bearing in phosphor bronze bearing housing,

11. laser cut and hand finished acetyl arm pillar mounted cradle for the armrest,

12. thick water-cut stainless steel motor mounting,

13. two-part mag lev ring bearing on main bearing, relieving thrust plate pressure and consequent reduction of friction & noise,

14. solid silver wiring throughout,

15. renovation of rosewood plinth,

16. rebuilding of internal hidden elements of plinth (eg internal mahogany top-plate supports)

17. other minor aspects....polishing of bearing shaft tip, etc...

and it is sounding SO good.....

Thirdly, when reading the thread, I notice that a few of you had talked about living in the UK, in Sheffield, in S11 or S7.

When I was a young guy, I remember Sheffield was world-famous for its steel works and I remember drinking Magnet ale...in fact the famous Sheffield United football team fans' song refers to 'Magnet' ale produced locally by John Smith's Brewery, a packet of Woodbines cigarettes, a pinch of snuff(tobacco), a night out in Sheffield and a greasy chip butty.

The full lyrics to Sheffield United's Greasy Chip Butty song are:

You fill up my senses Like a gallon of Magnet

Like packet of Woodbines

Like a good pinch of snuff

Like night out in Sheffield

Like a greasy chip butty

Like Sheffield United Come thrill me again....

Na Na Naa Naa Naaaaa, Oooooooh!"

Recognise it?

Well the thing is...

I was born in Sheffield S11 too...and lived there until I was 17....

There MUST have been something in the water....

Secondly, yesterday, after a few weeks of experimenting, I had managed to use mag lev on a Linn Sondek LP12, which, although it is alternately cast as an angel or a villain in the world of hifi, certainly has, in its natural form, a really musical toe tapping ability. For a few months now, a) because I am on a budget, and b) because I have engineering skills and can't ever leave well alone, I have been rebuilding my LP12 with:

1. a CAD designed water-cut single piece titanium subchassis & arm mount,

2. a CAD redesigned thicker water-cut stainless steel top plate,

3. new 7pm motor position,

4. new external & internal electronics,

5. thicker & more rigid higher tensile steel bolt & locknut components,

6. machined corian armboard,

7. machined corian baseplate,

8. lathe turned dural thickened bearing housing,

9. silicon or rubber rings on crucial parts to damp resonances,

10. molybdenum sulphide greased ruby motor bearing in phosphor bronze bearing housing,

11. laser cut and hand finished acetyl arm pillar mounted cradle for the armrest,

12. thick water-cut stainless steel motor mounting,

13. two-part mag lev ring bearing on main bearing, relieving thrust plate pressure and consequent reduction of friction & noise,

14. solid silver wiring throughout,

15. renovation of rosewood plinth,

16. rebuilding of internal hidden elements of plinth (eg internal mahogany top-plate supports)

17. other minor aspects....polishing of bearing shaft tip, etc...

and it is sounding SO good.....

Impressive, mate.

I'd also be interested to know what made you decide on #2 - in comparison, say, to a CF top-plate? Does your new top-plate use the same fixing bolts/ screws as the stock one? And what does the extra thickness deliver?

And I have #18 for you - but you need access to a sophisticated (CNC?) lathe. That is, to get both the inner & outer platters dynamically balanced!

An Aussie on Stereo Net Australia (SNA) had this done and, on the basis of his review, I decided to get mine done. Haven't got them back from the guy, yet, though (so I'm vinyl-less ATM).

Regards,

Andy

Bearing thoughts

Hi Guys,

I have read parts of this thread with great interest!

Me and a few friends made an experiment with a DIY Platine Verdier about 20 years ago and came to the conclusion that it sounded better with the platter resting on the ball than not. Better dynamics in the lower registers and an overall more stable presentation was the result from the second the ball was in place. I do not know how much weight that was put on the ball but it was not much at all, we are talking about a lot less than 100g here .

.

Reading through a few posts in this thread got me thinking, if mechanical grounding is so important maybe a zero play bearing like the one used in the Well Tempered Record Player (without the bottom ball though) can be used to good effect here. A non inverted bearing with the sleeve replaced by two V-shaped pieces of POM would be a good start. If the force from the belt is not enough to bias the bearing this could be done by small modifications to the magnet circuit. One could either tilt the lower magnet plate down slightly on the side towards the motor or simply remove a few magnets on that side.

BR,

Anders

Hi Guys,

I have read parts of this thread with great interest!

Me and a few friends made an experiment with a DIY Platine Verdier about 20 years ago and came to the conclusion that it sounded better with the platter resting on the ball than not. Better dynamics in the lower registers and an overall more stable presentation was the result from the second the ball was in place. I do not know how much weight that was put on the ball but it was not much at all, we are talking about a lot less than 100g here

Reading through a few posts in this thread got me thinking, if mechanical grounding is so important maybe a zero play bearing like the one used in the Well Tempered Record Player (without the bottom ball though) can be used to good effect here. A non inverted bearing with the sleeve replaced by two V-shaped pieces of POM would be a good start. If the force from the belt is not enough to bias the bearing this could be done by small modifications to the magnet circuit. One could either tilt the lower magnet plate down slightly on the side towards the motor or simply remove a few magnets on that side.

BR,

Anders

Attachments

interesting thread, also because I am planning to make my own TT.

I had drawn a lot of plans with a normal bearing like we all now them with the ceramic bal at the button.

Than I saw this thread and began thinking about it, this must be the way to go I thought.

So after some searching I saw that the Da Vinci Audio Gabriel AAS MK2 also used a magnetic bearing.

Here is a photo of that one :

Could some one help with calculating how much magnets you would need for a 20 kilo platter ?

Thanks

I had drawn a lot of plans with a normal bearing like we all now them with the ceramic bal at the button.

Than I saw this thread and began thinking about it, this must be the way to go I thought.

So after some searching I saw that the Da Vinci Audio Gabriel AAS MK2 also used a magnetic bearing.

Here is a photo of that one :

An externally hosted image should be here but it was not working when we last tested it.

Could some one help with calculating how much magnets you would need for a 20 kilo platter ?

Thanks

No point calculating you need to build in adjustability, either in the number of magnets you can use or the distance they can be spaced from the opposing magnet. you'll never get the ride height and damping correct by estimating or calculating, it has to be tuned by eye and ear.

Links are not available anymore.I just completed my magnetic bearing using opposing ring magnets. It took me awhile to find the right strength and magnets that would fit my upper & lower bearing housings. I built my turntable with my own inverted bearing design that worked very well to support the 36 pound platter. I initially used a tungsten carbide thrust plate but I always wanted to relieve the immense force it had to undertake to support the high mass platter. Anyway, that was over a year ago and after searching on & off I finally found a pair of magnets that fit both my criteria.

After building a test fixture and measuring clearance, I was satisfied that machining the pockets and bonding the magnets would be the final test to see if the magnets would perform as I hoped they would.

I initially assembled the lower & upper bearing housings which was a challenge because of the 100 pounds of opposing force generated by the magnets. I had to machine a Delrin sleeve to extend the length of the inverted bearing shaft, after that I assembled both housings and placed the platter on top.

I did this on a granite surface plate so I could place a dial indicator on the platter to measure deviation. The total measured deviation from perfection was 0.1mm, hardly anything to be concerned with.

I then put it to the true test and actually played record after record. What an improvement! Ultra quiet and smooth as silk, well worth all the effort. Below is an image of the lower bearing housing that shows one of the ring magnets bonded to the lower housing. The magnet is nickel plated. Another image shows the complete turntable.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Could you please reup plz?

Thanks in advance.

Ok, the center shaft on a magnetic bearing design is to solve the imposibility of a estable floating platter without any mechanical self-centering device...

But and this solution?

Used on the "Mercure Turntable": Mercury Turntable

Could it be used instead?

(sorry for my poor english)

But and this solution?

Used on the "Mercure Turntable": Mercury Turntable

Could it be used instead?

(sorry for my poor english)

HI Dear, some one year ago we interchange some ideas related to bearing magnetic suspension, i have a RX1500 micro seiki with aluminium platter and vacumm pump. Unluckely it's not with air suspension and for that reason i start to investigate, I could solution the problem and i made a new axle in stainless antimagnetic copying the orginal axle with so close tolerances, and i prolonged i to the botton for acoplate one 5cm neodymiun magnet and make a coup for the other one scrweed to the bearing original one, i rise the weight of the plater in 20kg and balanced it and the result was amazing, the turntable work very good. The engine now is a little stressed at the starting but once it turn, nothing can't stop it. If you want the pics and the plans, I did it with a machiner in Argentina, they are a close friends because i lived there for 47 years.

Best Regards

Esteban

Best Regards

Esteban

A source of small, cheap neodymium magnets, with force charts: Rare Earth Neodymium Magnets: Build Your Custom Magnet Sets Here

80 2.5x7 cylindrical magnets would generate 94 kg of force and cost 20 CAD. Magnet strength diminishes as a square of the distance. But a turntable only needson the order of a 1-3 mm.

80 2.5x7 cylindrical magnets would generate 94 kg of force and cost 20 CAD. Magnet strength diminishes as a square of the distance. But a turntable only needson the order of a 1-3 mm.

hello I began this post after reading it because I had been experimenting with levitation tray on my turntable.

I had given up because it was difficult for me to find the right magnets and the experiment would become very expensive to test various types of magnets.

So, after reading this post, I would therefore like to revisit the issue.

The acrylic plate of my platinum weighs + / - 8.5 kg and is 80mm thick ...

the diameter of the bearing is 40mm at its base, so I had thought of two ring magnets D60mm xd 40mm x 5mm ep, one fixed (the base) and the other inserted into the tray so obtain a distance of 1mm between the two, I thought adjusting the insertion depth of the magnet to reach the plateau at the correct distance of 1mm.

The problem with this kind of dimension is not common in this type of magnet, and I do not know how to grade (too repulsive or too little, I only have 20mm of adjustment range in the acrylic shelf (depth of ebcastrement ..)

Or do the alternative "ynwoan" and make two hard pmma or other dimensions of the ring magnets that I search and add several small magnets inside the cylinder style D8mm 5mm ep?

But the problem lies: what rank and choose how many magnets?? I think eventually achieve the two rings and drill holes as much as possible, then insert the magnets if the repulsion is too strong, I removed to obtain the correct distance (1mm) and then I realized my rings Definitive Media ...

By cons if it is not strong enough problem because I can not play on the outside diameter, so the number of holes ...

Have you any idea?

(I attached some pictures of the plateau and the axis) ( sorry for my bad english...google translate)

I had given up because it was difficult for me to find the right magnets and the experiment would become very expensive to test various types of magnets.

So, after reading this post, I would therefore like to revisit the issue.

The acrylic plate of my platinum weighs + / - 8.5 kg and is 80mm thick ...

the diameter of the bearing is 40mm at its base, so I had thought of two ring magnets D60mm xd 40mm x 5mm ep, one fixed (the base) and the other inserted into the tray so obtain a distance of 1mm between the two, I thought adjusting the insertion depth of the magnet to reach the plateau at the correct distance of 1mm.

The problem with this kind of dimension is not common in this type of magnet, and I do not know how to grade (too repulsive or too little, I only have 20mm of adjustment range in the acrylic shelf (depth of ebcastrement ..)

Or do the alternative "ynwoan" and make two hard pmma or other dimensions of the ring magnets that I search and add several small magnets inside the cylinder style D8mm 5mm ep?

But the problem lies: what rank and choose how many magnets?? I think eventually achieve the two rings and drill holes as much as possible, then insert the magnets if the repulsion is too strong, I removed to obtain the correct distance (1mm) and then I realized my rings Definitive Media ...

By cons if it is not strong enough problem because I can not play on the outside diameter, so the number of holes ...

Have you any idea?

(I attached some pictures of the plateau and the axis) ( sorry for my bad english...google translate)

Attachments

Last edited:

Some year ago I modify a Thorens with magnetic platter for avoid the rumble noise, I found a very annoying problem, the tonearm was influenced for the magnetic field and the whole work went to the garbich. The problem is there are no efficient measures to do that. Right now the solution became of make a prolongation of the axle further the space of the bush in the botton further the ball under the turntable. More magnetic power, more distance you have to take. I use anti-magnetic stainless steel and I have to make a gunmetal coup for put the magnet in the screwed in the botton part of the axle's bush , The magnets are two: one in the coup and one attached to the botton of the axle of 50mm diameter for 20mm of tall each. The gap between the magnets is close to 0,1mm with the weight of 24kg. I made a mold of plaster the inner part of the platter and then with this mold I constructed another to be able to put lead melted which finally was stuck within the plate. I had to reinforce the springs of the suspension system but the result was an amazing turntable.

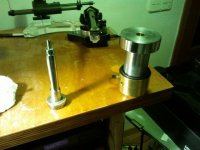

The Magnetic platter

The cup behind the axle contain the 5cmø neodym magnet and the other is possible to see in the axle. Is possible to see the original axle (steel) and the new one (nonmagnetic stainless steel)

This are the parts I assembled for modify the Micro Seiki RX1500 VG

The cup behind the axle contain the 5cmø neodym magnet and the other is possible to see in the axle. Is possible to see the original axle (steel) and the new one (nonmagnetic stainless steel)

Attachments

-

2012-11-08 18.44.27.jpg95.5 KB · Views: 218

2012-11-08 18.44.27.jpg95.5 KB · Views: 218 -

2012-11-08 18.49.04.jpg94.9 KB · Views: 178

2012-11-08 18.49.04.jpg94.9 KB · Views: 178 -

2012-11-08 18.48.06.jpg93.3 KB · Views: 158

2012-11-08 18.48.06.jpg93.3 KB · Views: 158 -

2012-11-08 18.45.57.jpg98 KB · Views: 157

2012-11-08 18.45.57.jpg98 KB · Views: 157 -

2012-11-08 18.45.08.jpg100.1 KB · Views: 181

2012-11-08 18.45.08.jpg100.1 KB · Views: 181 -

2012-11-08 18.44.55.jpg100.7 KB · Views: 187

2012-11-08 18.44.55.jpg100.7 KB · Views: 187 -

2012-11-08 18.44.37.jpg95.6 KB · Views: 195

2012-11-08 18.44.37.jpg95.6 KB · Views: 195 -

2012-11-08 18.47.29.jpg100 KB · Views: 260

2012-11-08 18.47.29.jpg100 KB · Views: 260 -

2012-11-08 18.49.59.jpg99.9 KB · Views: 187

2012-11-08 18.49.59.jpg99.9 KB · Views: 187

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Magnetic turntable bearing