O.K I'm no engineer so my explination may be a little off target..............

Thorens TD160

I want to put my platter and sub-platter onto a whole new base. But I don't want to use the suspended sub-chassis that sits underneath. But this houses the bearing/casing that the sub-platter sits into and rotates on. I have tried to get this off, but it looks as though it is welded to the sub-chassis. Am I right in thinking that this housing is welded on? If so can you get another that could be used? Or should I cut that piece off and attach it to the new base I wish to use.............

Any suggestions would be great....

P.S I don't have a wealth of machinery to use, so I'm limited as to how much I can do.

Brett

Thorens TD160

I want to put my platter and sub-platter onto a whole new base. But I don't want to use the suspended sub-chassis that sits underneath. But this houses the bearing/casing that the sub-platter sits into and rotates on. I have tried to get this off, but it looks as though it is welded to the sub-chassis. Am I right in thinking that this housing is welded on? If so can you get another that could be used? Or should I cut that piece off and attach it to the new base I wish to use.............

Any suggestions would be great....

P.S I don't have a wealth of machinery to use, so I'm limited as to how much I can do.

Brett

Hi,

check your bearing for wear first.

Clean all the old oil out and clean off the spindle.

Reassemble and check for looseness at the turntable rim. Up/down is equivalent to sideways slop in the bearing.

If it's too far gone it's probably not worth the effort of the rebuild.

A good machine shop might be able to remove the old bushes and line bore the new ones to a good fit to the spindle, but it'll not be cheap.

check your bearing for wear first.

Clean all the old oil out and clean off the spindle.

Reassemble and check for looseness at the turntable rim. Up/down is equivalent to sideways slop in the bearing.

If it's too far gone it's probably not worth the effort of the rebuild.

A good machine shop might be able to remove the old bushes and line bore the new ones to a good fit to the spindle, but it'll not be cheap.

Brett,

I thought about it 5 years ago, when installing the DC motor

in my Thorens TD 145.

The bearing is made of a steel tube set in the sub-chassis,

to be able to reuse it you will have to cut the subchassis

around say 2 to 3" diameter from the center to be able to

set it in your new chassis...

A lot of work, but douable...

I was thinking of a chassis like the Rega P25

You need to find someone capable of cutting the subchassis

of your TD 160 before going further

then You'll have to build the new TT base

Better go for a BIX turntable, will cost less trouble

and in the mean time still enjoy your Thorens.

And sell it as collector item further...

http://www.diyhifisupply.com/diyhs_bix.htm

PS: as AndrewT say's check for the bearing wear before,

but this piece can be replaced with a teflon coated new bearing

if the spindle has no wear...

See:

http://www.directindustry.fr/prod/ggb/palier-lisse-en-bronze-4800-12627.html

http://www.directindustry.fr/prod/rbc-bearings/palier-lisse-autolubrifiant-en-metal-16837-37389.html

these are similar to the original bearing, installed press fit...

Regards.

Alain.

I thought about it 5 years ago, when installing the DC motor

in my Thorens TD 145.

The bearing is made of a steel tube set in the sub-chassis,

to be able to reuse it you will have to cut the subchassis

around say 2 to 3" diameter from the center to be able to

set it in your new chassis...

A lot of work, but douable...

I was thinking of a chassis like the Rega P25

You need to find someone capable of cutting the subchassis

of your TD 160 before going further

then You'll have to build the new TT base

Better go for a BIX turntable, will cost less trouble

and in the mean time still enjoy your Thorens.

And sell it as collector item further...

http://www.diyhifisupply.com/diyhs_bix.htm

PS: as AndrewT say's check for the bearing wear before,

but this piece can be replaced with a teflon coated new bearing

if the spindle has no wear...

See:

http://www.directindustry.fr/prod/ggb/palier-lisse-en-bronze-4800-12627.html

http://www.directindustry.fr/prod/rbc-bearings/palier-lisse-autolubrifiant-en-metal-16837-37389.html

these are similar to the original bearing, installed press fit...

Regards.

Alain.

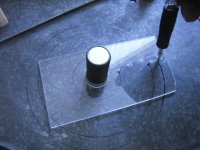

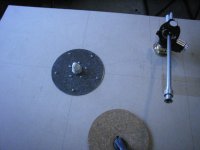

Sub-chassis

Alain,

That steel seems rather hard, you could be right about it being a big job. I will do a test on it and try drilling one small hole to see how hard it is before i go go any further.

I was going to cut it out about 120mm across and then drill a lot of holes around so as to get a good solid contact onto the the MDF plinth.

I'm thinking trailing a MDF-Cork-MDF combination. 20mm MDF onto a 4mm Cork layer, then mounting to another bottom layer of MDF. This I might place holes around and fill with a bottle a 10kg of shot pallets to give that bottom layer extra weight.

Alain; Question for you. I have been looking at ebay, at some tone arms and they seem to be a little pricey for my NZ dollar. How good are the original arms, if set up properly. Is worth looking at getting something else?

Brett

Alain,

That steel seems rather hard, you could be right about it being a big job. I will do a test on it and try drilling one small hole to see how hard it is before i go go any further.

I was going to cut it out about 120mm across and then drill a lot of holes around so as to get a good solid contact onto the the MDF plinth.

I'm thinking trailing a MDF-Cork-MDF combination. 20mm MDF onto a 4mm Cork layer, then mounting to another bottom layer of MDF. This I might place holes around and fill with a bottle a 10kg of shot pallets to give that bottom layer extra weight.

Alain; Question for you. I have been looking at ebay, at some tone arms and they seem to be a little pricey for my NZ dollar. How good are the original arms, if set up properly. Is worth looking at getting something else?

Brett

enzedone,

For a new tonearm, the original model is worth a 600/800U$ base...

So to get better, you'll have to go to 800 to 1200 U$ and used at 400/800U$

Costly, I was thinking of building a "Schroeder"

but have no time to do the mecanical schematic for now...

Look on Audiogon.com for used ones...

Depends also if you want to use a MC cartridge ?

It's why I wanted to go for a Rega P25 or BIX , be able to set a nice Kontrapunkt A

Denon DL103R or Shelter, all low output MC catridges

to get the best of my Allen Wright FVP5A phono stage...{pending project...}

Arms:

Rega RB600

Vpi JMW 9 or 10

Graham Robin

PS: Think of a steel plate about 4 to 5 mm between 2 layers of cork

or butyl or silicone or polyurethane to get some more mass for the bearing support

Regards.

Alain.

For a new tonearm, the original model is worth a 600/800U$ base...

So to get better, you'll have to go to 800 to 1200 U$ and used at 400/800U$

Costly, I was thinking of building a "Schroeder"

but have no time to do the mecanical schematic for now...

Look on Audiogon.com for used ones...

Depends also if you want to use a MC cartridge ?

It's why I wanted to go for a Rega P25 or BIX , be able to set a nice Kontrapunkt A

Denon DL103R or Shelter, all low output MC catridges

to get the best of my Allen Wright FVP5A phono stage...{pending project...}

Arms:

Rega RB600

Vpi JMW 9 or 10

Graham Robin

PS: Think of a steel plate about 4 to 5 mm between 2 layers of cork

or butyl or silicone or polyurethane to get some more mass for the bearing support

Regards.

Alain.

no worries

If you use a grinder make sure you get as close as possible to the outer line so you don't end up with too much filing, but be carefull not to take out too big a chunks.

The Plinth dimensions are 500mm x 400mm. The platter will be sitting dead centre.

Standard 16 toonearm. With my own stand for it made from 20mm plumbing pipe which I will re-polish and then coat with a clear coat

If you use a grinder make sure you get as close as possible to the outer line so you don't end up with too much filing, but be carefull not to take out too big a chunks.

The Plinth dimensions are 500mm x 400mm. The platter will be sitting dead centre.

Standard 16 toonearm. With my own stand for it made from 20mm plumbing pipe which I will re-polish and then coat with a clear coat

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- New plinth for TD160