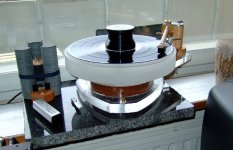

Jep, quite heavy.. the TT and the stone platform are both a little over 15 kilos. Like in the Scheu original there is lead inside the round collar. Only buying lead pebbles would have been quite expensive so I melt down some car/truck tire weights for it. It looked kind of ugly though by its self so I pored some coffee to the sides.

The stone platform is actually a gravestone (not a used one though ) Wasn't quite first class so I got it cheap. Also the pillars around the motor are from the same stone worker. They are cutouts of completed gravestones.

) Wasn't quite first class so I got it cheap. Also the pillars around the motor are from the same stone worker. They are cutouts of completed gravestones.

The platter, bearing and motor are from Scheu Analog / the arm is of coarse a Schröder copy.

-jugi

The stone platform is actually a gravestone (not a used one though

The platter, bearing and motor are from Scheu Analog / the arm is of coarse a Schröder copy.

-jugi

IZHAKKATZ, sounds quite good..

In many respects it beats my CDP, a 2k euro player... the TT, cart and also phone pre are still running in - so we'll see.

Also, since I have very little experiance with proper TT:s I'll probably buy a Scheu classic tonearm for some kind of reference. Also I'm thinking of building the Poul Ladegaard's Air Bearing Tangential Tonearm to see if it's a good one.

- Jugi

Another picture too..

In many respects it beats my CDP, a 2k euro player... the TT, cart and also phone pre are still running in - so we'll see.

Also, since I have very little experiance with proper TT:s I'll probably buy a Scheu classic tonearm for some kind of reference. Also I'm thinking of building the Poul Ladegaard's Air Bearing Tangential Tonearm to see if it's a good one.

- Jugi

Another picture too..

Attachments

jugi63 said:The stone platform is actually a gravestone (not a used one though) Wasn't quite first class so I got it cheap. Also the pillars around the motor are from the same stone worker. They are cutouts of completed gravestones.

That must sound dead

Looks as a very nice turntable, congrats!

Hello jugi63,

Nice job on the arm, but I'd need a little more than just one pic to give you some advice on how to improve upon it. Any problems you have/had with it? Did you use maple for the base cylinder and armwand?

Cheers,

Frank

@SunRa: It's not a Scheu designed arm... ;-)

Nice job on the arm, but I'd need a little more than just one pic to give you some advice on how to improve upon it. Any problems you have/had with it? Did you use maple for the base cylinder and armwand?

Cheers,

Frank

@SunRa: It's not a Scheu designed arm... ;-)

Hi Frank! Thanks for answering..

Thanks also for the inspiration!

I'm amazed of the sound even now. So clear and musical! The sound of instruments and especially the resonance of string instruments are so much more authentic!

With the arm everything is basicaly pretty clear but the function its self isn't quite as good (You are right - no easy task). The tonearm tends to wobble from side to side if lowered to where I think if should be. The gap between the magnets is now some 3 mm. Any lower and it flips from side to side. Although the arm sounds suprisingly good even now, I suppose the gap should be about 1mm?

So would this be a defect of the hole in the magnet not being exactly in the center? The magnet hole is spark drilled at a local firm, so it should be fairly well centered. Or also maybe the antiskating disturbes the ballance - a too strong line? 23kg pull, 0.35mm thick, I think it was.. (not home right now).

The wood of the arm wand is alder, the other wooden parts are beech. After taking the picture I added a small weight along the underside of the wand to rise the effective mass a little to better suite the Shelter 501 II cart. Also I'm thinking of soaking the wand in epoxy to further resist resonancies. Worth it?

If I can't get the magnets close enough to each other, I'll probably save up to buy a Scheu Cantus or Classic - only I'm also thinking that maybe the version I already have may sound better than the Classic mkII at least?

Also I apreciate the fact that this is Your patent and profesion, so would you rather discuss (asuming you will discuss) this in private?

Thanks!

- Jugi

Thanks also for the inspiration!

I'm amazed of the sound even now. So clear and musical! The sound of instruments and especially the resonance of string instruments are so much more authentic!

With the arm everything is basicaly pretty clear but the function its self isn't quite as good (You are right - no easy task). The tonearm tends to wobble from side to side if lowered to where I think if should be. The gap between the magnets is now some 3 mm. Any lower and it flips from side to side. Although the arm sounds suprisingly good even now, I suppose the gap should be about 1mm?

So would this be a defect of the hole in the magnet not being exactly in the center? The magnet hole is spark drilled at a local firm, so it should be fairly well centered. Or also maybe the antiskating disturbes the ballance - a too strong line? 23kg pull, 0.35mm thick, I think it was.. (not home right now).

The wood of the arm wand is alder, the other wooden parts are beech. After taking the picture I added a small weight along the underside of the wand to rise the effective mass a little to better suite the Shelter 501 II cart. Also I'm thinking of soaking the wand in epoxy to further resist resonancies. Worth it?

If I can't get the magnets close enough to each other, I'll probably save up to buy a Scheu Cantus or Classic - only I'm also thinking that maybe the version I already have may sound better than the Classic mkII at least?

Also I apreciate the fact that this is Your patent and profesion, so would you rather discuss (asuming you will discuss) this in private?

Thanks!

- Jugi

@SunRa: It's not a Scheu designed arm... ;-)

Sorry I meant schroeder... it looks pretty similar to the last schroeder, the one reviewed by 6moons

Hello Jugi,

Just send me a private mail after tuesday and I'll tell you what makes the arm flip either side when closing the gap..., but it has nothing to do with the antiskating - and the thread diameter is in the ballpark .

.

Soaking the armwand in epoxy isn't necessarily going to make it less resonant, it'll just change the res.-distribution.

Cheers,

Frank

Just send me a private mail after tuesday and I'll tell you what makes the arm flip either side when closing the gap..., but it has nothing to do with the antiskating - and the thread diameter is in the ballpark

Soaking the armwand in epoxy isn't necessarily going to make it less resonant, it'll just change the res.-distribution.

Cheers,

Frank

Consider 'skinning' the arm wand, like an egg. This will work wonders. Long story.

If you have multiple wands, that is. To test each type out, or at least, that way you can reverse the situation if you don't like it.

Try the artist's brand "tri-art" brand 'topcoat', a watered down, ultra thin layer. (A highly damping but ultra fast hard and flexable acrylic-urethane mix-same base resin as BMW's vehicle topcoat, I believe.)

The best way to do it, is to thin the topcoat with distilled water, about 4:1-5:1, stir thoroughly.

Tape off the parts that need be clean for screwing or mating purposes D), and then dip thoroughly...and shake off the excess. Sounds rude, but this is likely a path to getting the resonance out of the armwand. The dipping and then the shaking off will create a layer that is even in thickness. Or, dip and then wash off (use a lint free cloth, go fast, this stuff gets sticky very fast). Let dry, maybe do another. The slight soaking into the wood from a few dippings, will do the trick. Ultra thins lead to the highest level of musical pleasure.

D), and then dip thoroughly...and shake off the excess. Sounds rude, but this is likely a path to getting the resonance out of the armwand. The dipping and then the shaking off will create a layer that is even in thickness. Or, dip and then wash off (use a lint free cloth, go fast, this stuff gets sticky very fast). Let dry, maybe do another. The slight soaking into the wood from a few dippings, will do the trick. Ultra thins lead to the highest level of musical pleasure.

Same treatment for the rest of the wood.

It will take up to 6 months to fully cure the topcoat. Some say two years later, it is still hardening. Viagra for wood that needs permanent hardening. It has even been used to coat entire log cabins (soaking of all logs-massive wood!-before the erection stage)

If you have multiple wands, that is. To test each type out, or at least, that way you can reverse the situation if you don't like it.

Try the artist's brand "tri-art" brand 'topcoat', a watered down, ultra thin layer. (A highly damping but ultra fast hard and flexable acrylic-urethane mix-same base resin as BMW's vehicle topcoat, I believe.)

The best way to do it, is to thin the topcoat with distilled water, about 4:1-5:1, stir thoroughly.

Tape off the parts that need be clean for screwing or mating purposes

Same treatment for the rest of the wood.

It will take up to 6 months to fully cure the topcoat. Some say two years later, it is still hardening. Viagra for wood that needs permanent hardening. It has even been used to coat entire log cabins (soaking of all logs-massive wood!-before the erection stage)

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Finished DIY turntable and arm! (pic)