I'm trying to plan out a diy turntable, but I've never taken apart a good one so I really don't know how the bearing should work.

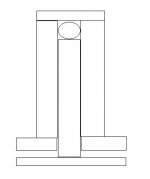

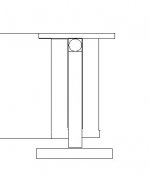

I drew out a quick and dirty layout which is attached. Is there anything that looks incredibly stupid? Would this bearing work well enough for a turntable?

Thanks

I drew out a quick and dirty layout which is attached. Is there anything that looks incredibly stupid? Would this bearing work well enough for a turntable?

Thanks

Attachments

Cloth Ears said:You need an axial ball-bearing race. Think of how smoothly a large roulette wheel glides around

- almost as easily as it removes your money.

One between the flanges of the teflon sleeve and the steel spindle is where you want it.

Hi,

Erm....... no you don't. Far too noisy. Ball bearing + thrustpad is what's needed.

Not necessarily at this low rotational speeds. But I agree, a single centered ball would of course be the much more commen solution.Far too noisy

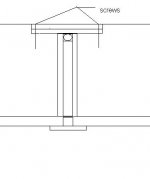

You know I think it would be better to do something more like this, just use a plain teflon sleeve that buts up against a 3" metal disc sunk into the surface of the platter, and held by 4 longish wood screws. Also go to a .5" shaft and sleeve ID with a .5" steel ball.

Oh, if you texture the surface to be glued, teflon will adhere. It'll never be a strong bond, but you can use it for light duty stuff.

Oh, if you texture the surface to be glued, teflon will adhere. It'll never be a strong bond, but you can use it for light duty stuff.

Attachments

Wouldn't that change the ID of the sleeve?

Although, if the teflon sleeve had a flange the same diameter as the metal plate, I could drill through both of them and use screws to hold them both to the platter like this. That solves the problem of the sleeve rotating within the platter

Although, if the teflon sleeve had a flange the same diameter as the metal plate, I could drill through both of them and use screws to hold them both to the platter like this. That solves the problem of the sleeve rotating within the platter

Additionally, yes. But be sure - the sleev wouldn't rotate, the friction of the bearing is (let's say - should beThat solves the problem of the sleeve rotating within the platter

How much better would a tungsten ball work than a hardened stainless steel one? I can get 10 stainless for $8, and one tungsten for $17.

Should I use a ball of the same diameter as the shaft, or slightly smaller?

I should clarify, the stainless balls are 440, and there are also carbon steel balls for $2 for 10.

Should I use a ball of the same diameter as the shaft, or slightly smaller?

I should clarify, the stainless balls are 440, and there are also carbon steel balls for $2 for 10.

If the thrust plate is very hard, different ball diameters make no difference, as they always will contact the plate in one very small point only. A ball with the diameter of the shaft has one advantage: it is automatically centered on the spindle. You may achive this with a smaller ball as well, if you drill a hole in the spindle's center for holding the ball in place.

Hardness is not that important - at least not in the first years. Nowadays, many TT maufacturers are going for ceramic balls (silicon nitride, silicon carbide, tungsten carbide) as they have become rather cheap and last forever.

But: it is absolutely okay to start with a steel ball.

Hardness is not that important - at least not in the first years. Nowadays, many TT maufacturers are going for ceramic balls (silicon nitride, silicon carbide, tungsten carbide) as they have become rather cheap and last forever.

But: it is absolutely okay to start with a steel ball.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY turntable, am I just missing the point?