Nanook's tonearm

Very interested by the look of Nanook's tonearm. Must admit that I have experimented with a variety of arrow shafts - wood, carbon, fibreglass and aluminium - but am currently very excited about this;

http://www.hexshaftarrows.com/

If you think of an old fishing rod that is made out of split cane, then you will get the idea. They take the wood and macine it to produce a number of equilateral triangles. Next, six are selected and glued together to form a shaft with a hexagonal cross section which is then turned into one with a cylindrical cross section. The big advantage is that the grain of the wood resembles the spokes in a bicycle wheel, it radiates out from the centre of the shaft promising greater dimensional stability.

As soon as I can find a supplier over here I fully intend to use one of these shafts as an arm wand.

Very interested by the look of Nanook's tonearm. Must admit that I have experimented with a variety of arrow shafts - wood, carbon, fibreglass and aluminium - but am currently very excited about this;

http://www.hexshaftarrows.com/

If you think of an old fishing rod that is made out of split cane, then you will get the idea. They take the wood and macine it to produce a number of equilateral triangles. Next, six are selected and glued together to form a shaft with a hexagonal cross section which is then turned into one with a cylindrical cross section. The big advantage is that the grain of the wood resembles the spokes in a bicycle wheel, it radiates out from the centre of the shaft promising greater dimensional stability.

As soon as I can find a supplier over here I fully intend to use one of these shafts as an arm wand.

hummmmmmmmm

probably from magnetic pick up, and so metalised mylar, copper, aluminum are not going to help (need steel or mu metal for magnetic shielding) - they will help with electrostatic shielding - for higher frequencies including some rejection of all that RF junk that is around these days - good to keep that out of the preamp

possible solutions:

find the source and reposition if posible

shield the source, (cassette deck motors often had mu metal shields)

and most important - twist the arm leads - ie a twisted pair - both leads pick up the magnetic field induced hum and hopefully the preamp will reject the common signal

most important - twist the arm leads - ie a twisted pair - both leads pick up the magnetic field induced hum and hopefully the preamp will reject the common signal

Hope this helps

Bill

Oh, I was going to provide a link to the Well Tempered site so people could look at their tone arm but when I checked the picture there does not help much.

probably from magnetic pick up, and so metalised mylar, copper, aluminum are not going to help (need steel or mu metal for magnetic shielding) - they will help with electrostatic shielding - for higher frequencies including some rejection of all that RF junk that is around these days - good to keep that out of the preamp

possible solutions:

find the source and reposition if posible

shield the source, (cassette deck motors often had mu metal shields)

and

most important - twist the arm leads - ie a twisted pair - both leads pick up the magnetic field induced hum and hopefully the preamp will reject the common signal

most important - twist the arm leads - ie a twisted pair - both leads pick up the magnetic field induced hum and hopefully the preamp will reject the common signal Hope this helps

Bill

Oh, I was going to provide a link to the Well Tempered site so people could look at their tone arm but when I checked the picture there does not help much.

I use a unipivot arm made from a section of fishing rod.

A very stiff section from a beach caster which has a nice taper.

The cartridge end is a piece of 2mm Tufnol sheet Araldited to the arm.

The back end is an 8mm stainless steel rod Araldited into the arm.

To make the pivot I drilled a hole half way through the arm into the stainless & polished it to a cone.

The pivot is a tungten ball, ball bearing pen tip washed out & lubricated.

Then around the pivot point is a heavy collar which takes the point of balance below the pivot point.

The balance weight is also well below center.

Bias is a Lenco weight & spiral.

A very stiff section from a beach caster which has a nice taper.

The cartridge end is a piece of 2mm Tufnol sheet Araldited to the arm.

The back end is an 8mm stainless steel rod Araldited into the arm.

To make the pivot I drilled a hole half way through the arm into the stainless & polished it to a cone.

The pivot is a tungten ball, ball bearing pen tip washed out & lubricated.

Then around the pivot point is a heavy collar which takes the point of balance below the pivot point.

The balance weight is also well below center.

Bias is a Lenco weight & spiral.

ColinA, got a pix?

I'm looking at doing something similar with a carbon fibre arrow shaft as well. Absolutely simple. Only thing particularly critical is the wiring, and the headshell . Everything else is pretty simple, unless of course you are a machinist with good materials,good machines, and good skills...

I'm looking at doing something similar with a carbon fibre arrow shaft as well. Absolutely simple. Only thing particularly critical is the wiring, and the headshell . Everything else is pretty simple, unless of course you are a machinist with good materials,good machines, and good skills...

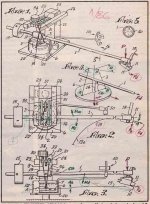

Attachments

Re: Re: Re: to bobhayes... and a rant

I know that Be Yamamura was making a prototype of thisconcept as early as 1990...I also made one with his help and it worked very well indeed.

Zen Mod said:

have you any sketch about pivoting headshell?

I know that Be Yamamura was making a prototype of thisconcept as early as 1990...I also made one with his help and it worked very well indeed.

Talking about fishingrods...my dad had some graphite bass rods, the handles are made to leave the rod exposed so you can leave your fingers on it...

Being a fishing rod it is quite rigid, and I suppose one doesn't need to use the very tip, the neat thing about these are the sensitivity... you can literaly feel vocal cords moving when you hold it to someone's neck and they speak.

What are the ideal qualities/functions of a tonearm?

Being a fishing rod it is quite rigid, and I suppose one doesn't need to use the very tip, the neat thing about these are the sensitivity... you can literaly feel vocal cords moving when you hold it to someone's neck and they speak.

What are the ideal qualities/functions of a tonearm?

Since this thread has started up again, here's what I made from a section of carbon tent pole, and has been in service for over a year. It's a little heavier than an arrow, and perhaps a fishing rod, but as far as my deaf ears are concerned, it sounds good. Very clean. My next upgrade will be the platter bearing as the current one rumbles.

The azimuth is adjusted by rotating the counterweight 'washers'.

The azimuth is adjusted by rotating the counterweight 'washers'.

Attachments

Making a Tonearm

Hey Bob

That's nice work

A couple of months ago, I got fedup with wornout headshell slots on two Micro graphite arms I have here. My idea was to change one of the straight arms into a j-shaped arm with an sme type female fitting at the end. Fortunately, I have a lathe and a milling machine so I could do all the work myself. One of the parameters was that I did not want to use any glues, even though I regularly use various industrial types which are very good.

I looked around for some suitable thinwall aluminium tubing and remembered about the wreckage of an r/c helicopter I picked out of a rubbish bag. Here I had two thinwall and very strong and light landing sleds which also had the correct curvature for my 301's setup.

The only problem was the new section was about 1.5mm smaller in dia than the old section and here I turned a polished brass adaptor sleeve. At the front end, I turned an aluminium 2-dia sleeve to take the sme socket.

All parts were precision turned and polished (the alu parts also anodised) and all previous internal earthtags were remade and carried forward to the shell. New wiring was installed and as the new arm was about 3g heavier than the old, I turned a brass insert which fits inside the threaded armweight carrier. This was carefully machined so that the calibrated armweight still shows its original calibrations.

Looks great and works well.

bulgin

Hey Bob

That's nice work

A couple of months ago, I got fedup with wornout headshell slots on two Micro graphite arms I have here. My idea was to change one of the straight arms into a j-shaped arm with an sme type female fitting at the end. Fortunately, I have a lathe and a milling machine so I could do all the work myself. One of the parameters was that I did not want to use any glues, even though I regularly use various industrial types which are very good.

I looked around for some suitable thinwall aluminium tubing and remembered about the wreckage of an r/c helicopter I picked out of a rubbish bag. Here I had two thinwall and very strong and light landing sleds which also had the correct curvature for my 301's setup.

The only problem was the new section was about 1.5mm smaller in dia than the old section and here I turned a polished brass adaptor sleeve. At the front end, I turned an aluminium 2-dia sleeve to take the sme socket.

All parts were precision turned and polished (the alu parts also anodised) and all previous internal earthtags were remade and carried forward to the shell. New wiring was installed and as the new arm was about 3g heavier than the old, I turned a brass insert which fits inside the threaded armweight carrier. This was carefully machined so that the calibrated armweight still shows its original calibrations.

Looks great and works well.

bulgin

It sounds a great deal better executed than mine!

I stuck an old machine screw in an electric drill and vice and 'hand turned' the uni pivot with a file. I think the off-cut thread became the counter weight screw, epoxied in the corbon shaft.

About 6 washers drilled off centre is the counterweight. Anti skate is a bit of bent wire and a piece of thread with a weight on it.

Talk about rough... I drilled one side of the carbon tube for the unipivot to enter, and the point of the pivot sits in the divot the drill made on the opposite wall of the tube. No proper bush.

I roughly filed flats on opposing sides of the tube end for the cartidge and clamp/handle.

Still... it works.

I stuck an old machine screw in an electric drill and vice and 'hand turned' the uni pivot with a file. I think the off-cut thread became the counter weight screw, epoxied in the corbon shaft.

About 6 washers drilled off centre is the counterweight. Anti skate is a bit of bent wire and a piece of thread with a weight on it.

Talk about rough... I drilled one side of the carbon tube for the unipivot to enter, and the point of the pivot sits in the divot the drill made on the opposite wall of the tube. No proper bush.

I roughly filed flats on opposing sides of the tube end for the cartidge and clamp/handle.

Still... it works.

mine is a bamboo unipivot arm

http://img186.imageshack.us/img186/2198/img0016jq5.jpg

http://img186.imageshack.us/img186/2198/img0016jq5.jpg

fergs1 said:Greetings L and G, too229 do you have any better pics of the arn? It looks interesting but the pic is tiny cheers ferg

http://img112.imageshack.us/img112/97/img0016vd0.jpg

I read somewhere that the amount of anti skate required lessens as the arm get closer to the centre. If the threaded weight type was made as a cup with the weight of the cup corresponding to the centre weight and had a small drainhole or holes in the bottom it could be suspended in a light viscous fluid with plenty of wall clearance and the cup would empty as the arm taversed the record pulling the cup weight above the fluid. Would it work?

jamikl

jamikl

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- making a tonearm...