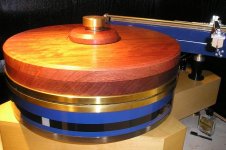

Here is the last incarnation of my homebrewed platter, which includes wooden upper layer. I glued two bubinga boards with the West epoxy and shaped it on CNC. Than the 36 mm chunk of wood was screwed to the underlaying 10 mm brass plate with 24 bronze wood screws and bolted to the lead loaded subplatter. Thus I'm trying to address the issue of wood dimensions/shape stabily.

The most pleasant improvement I noticed was the complete absence of accoustical feedback (resonance) of the stylus induced vibrations, which are oterways bounced back to stylus and cause nasty low fq peaks. If you heard heavy trucks suddenly entering some of your records background, you know what I mean. I never managed to get rid of it completely with aluminum and acrylic platter. Now I may confirm, wood is the way to go. The hardwood vibration properties suit vinyl very well, allowing low fq to pass and being absorbed further, without overdapming and sucking life from music.

The most pleasant improvement I noticed was the complete absence of accoustical feedback (resonance) of the stylus induced vibrations, which are oterways bounced back to stylus and cause nasty low fq peaks. If you heard heavy trucks suddenly entering some of your records background, you know what I mean. I never managed to get rid of it completely with aluminum and acrylic platter. Now I may confirm, wood is the way to go. The hardwood vibration properties suit vinyl very well, allowing low fq to pass and being absorbed further, without overdapming and sucking life from music.

Attachments

Just 4 layers of marine grade polyurethane varnish.Did you give the wood any other finish treatment to seal it

brass

- prevents wood from warping (wood is screwed to it),

- takes part in providing path for low fq vibration, having it's own good sonic signature,

- hepls to damp the upper mid vibration (ringing), by having layer of sorbotane between two brass layers (note, that the rigid coupling beween them is still there by means of 12 brass discs with all package bolted together),

- adding rotational mass.

Tee, I wish you luck with your own project. It's fun, I tell you!

Michael

Brass serves several goals:Can you explain a little further about the usage of the brass layer?

- prevents wood from warping (wood is screwed to it),

- takes part in providing path for low fq vibration, having it's own good sonic signature,

- hepls to damp the upper mid vibration (ringing), by having layer of sorbotane between two brass layers (note, that the rigid coupling beween them is still there by means of 12 brass discs with all package bolted together),

- adding rotational mass.

Tee, I wish you luck with your own project. It's fun, I tell you!

Michael

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.