Hello,

I am currently working on my duy turntable again. ANd i am finally gonna gt it done this time. MY whole picture is to have a seperate system, (turntable, motor pod and 2 tonearm pods) I will have a drilled material (mdf or plexi) as my foux shelf (holes drilled intoit to keep most componets in the same place). This will have 4 isolation feet prolly sorbothane or just wood or dampening material. I am having a bearing machined this week alonge with all remaining parts to get just the turntable together. The pods will be next couple of weeks.

Now the questions.

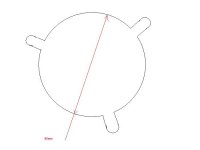

I have the plinth made out of acrillic 1 inch thick (2.54mm) and a bronze / stainless steel bearing hanging down in the middle. the legs are about 3.5 inches anf about 1.5 inch diameter. These i salvaged and are connected to a center rod with a set screw, the center rod has a pointed foot screwed onto it. and to hold it to the table there is a sleve with a set screw on top of the plexy.

question #1

Should i put a compound (contact cement) between the pointed feet and legs to advoid a vibration?

question #2

I was thinking of putting a 1/4 or 1/8 inch layer of sorbothane between the plinth and the leg and the sleve holding it on. @ reasons first togive adequite pressure (like a strong spring) and second to isolate it. when i tighten it i will put a weight on top of the collar possibily 10 pounds, to peload the sorbothane.

what are you thoughts on this construction. I am trying to save my self errors before i put it together, whitch will be when i get the bearing.

I have no recent pictures, but there are some here of the bad bearing of the plinth and plater.

http://www.spootystuff.com/projects/turntable_building.html

these pictures are real old.

thanks and a tip of my hat to roger waters (got me to finally finish my table) and someone who i forgot their name but has a awsome design of cutting boards and alumun.

FortyTwo

I am currently working on my duy turntable again. ANd i am finally gonna gt it done this time. MY whole picture is to have a seperate system, (turntable, motor pod and 2 tonearm pods) I will have a drilled material (mdf or plexi) as my foux shelf (holes drilled intoit to keep most componets in the same place). This will have 4 isolation feet prolly sorbothane or just wood or dampening material. I am having a bearing machined this week alonge with all remaining parts to get just the turntable together. The pods will be next couple of weeks.

Now the questions.

I have the plinth made out of acrillic 1 inch thick (2.54mm) and a bronze / stainless steel bearing hanging down in the middle. the legs are about 3.5 inches anf about 1.5 inch diameter. These i salvaged and are connected to a center rod with a set screw, the center rod has a pointed foot screwed onto it. and to hold it to the table there is a sleve with a set screw on top of the plexy.

question #1

Should i put a compound (contact cement) between the pointed feet and legs to advoid a vibration?

question #2

I was thinking of putting a 1/4 or 1/8 inch layer of sorbothane between the plinth and the leg and the sleve holding it on. @ reasons first togive adequite pressure (like a strong spring) and second to isolate it. when i tighten it i will put a weight on top of the collar possibily 10 pounds, to peload the sorbothane.

what are you thoughts on this construction. I am trying to save my self errors before i put it together, whitch will be when i get the bearing.

I have no recent pictures, but there are some here of the bad bearing of the plinth and plater.

http://www.spootystuff.com/projects/turntable_building.html

these pictures are real old.

thanks and a tip of my hat to roger waters (got me to finally finish my table) and someone who i forgot their name but has a awsome design of cutting boards and alumun.

FortyTwo

Attachments

Every small bit changes the perceived sound. As the materials you mention all have nil isolation properties at low frequencies all they'll acomplish will be modifiying the sound in the mid and high frequencies. Unless you actually listen to it there is practically no way to predict whether the change will be pleasing or not.

From my limited experiments with building i have noticed that the arm support has probably the strongest effect upon the sound. Of course plinth construction, glues and pointy feet are all very noticeable. A plinth i made changed dramatically from being just bolted from several layers of ply to being lead filled to being glued. Yes, i agonised over the type of glue - it does become a part of the plinth, but at the end just used epoxy.

From my limited experiments with building i have noticed that the arm support has probably the strongest effect upon the sound. Of course plinth construction, glues and pointy feet are all very noticeable. A plinth i made changed dramatically from being just bolted from several layers of ply to being lead filled to being glued. Yes, i agonised over the type of glue - it does become a part of the plinth, but at the end just used epoxy.

I will have to give it a try either way, i can then change the height between the leg and foot to compensate for the lack of sorbothane. I have this flexibility because of the construction method.

Therefore hainge alumun against acrillic is ok, there is no need for something between them?

FortyTwo

Therefore hainge alumun against acrillic is ok, there is no need for something between them?

FortyTwo

Who was this where is his posts

I am sorry but i cant seem to find a thred (or part of a thred) that had somes very astecially pleasing diy tt. IF someone could help me find it and point me twardws it i would like to copy his motor / tonearm pods and ask him a question.

The table was made from marine alumun and cuttingboard plastic. It has seperate pods for the tonearm and motor had a funkey shaped 3 footed base with huge ball bearings on the top of each foot section.

Thats all i can remember and describe well.

FortyTwo

I am sorry but i cant seem to find a thred (or part of a thred) that had somes very astecially pleasing diy tt. IF someone could help me find it and point me twardws it i would like to copy his motor / tonearm pods and ask him a question.

The table was made from marine alumun and cuttingboard plastic. It has seperate pods for the tonearm and motor had a funkey shaped 3 footed base with huge ball bearings on the top of each foot section.

Thats all i can remember and describe well.

FortyTwo

GazzaFloyd

I belive that any effort to truly get a unique design is commendable. Yours has one of the magor rules of building a DIY TT and that is great style. I am truely in live with the art-decco design, and i belive we arekeeping that mechanical look alive today.

I do have a question nabout your pods (motor and tonearm). How did you make the top and bottom. Did you machine a grove intothem for the cylinder to sit into or are they flat and have some centering pins in them. I would like to end up with something quite simular.

Currently i am still waiting for the bearing to come back from the machinist so i am building a roger waters style tonearm out of acrillic and carbon. If my parts come back i will finish the turntable

FortyTwo

I belive that any effort to truly get a unique design is commendable. Yours has one of the magor rules of building a DIY TT and that is great style. I am truely in live with the art-decco design, and i belive we arekeeping that mechanical look alive today.

I do have a question nabout your pods (motor and tonearm). How did you make the top and bottom. Did you machine a grove intothem for the cylinder to sit into or are they flat and have some centering pins in them. I would like to end up with something quite simular.

Currently i am still waiting for the bearing to come back from the machinist so i am building a roger waters style tonearm out of acrillic and carbon. If my parts come back i will finish the turntable

FortyTwo

I GOT MY BEARING!

I just got my bearing back today. I polished the staiunless and also the bronze. Here are a few pics of assembly. Now all i need to do is build a motor assy and tonearm pod and i will be listening on it.

This pic is of the bearing after polishing and i am just about to assemble it.

I just got my bearing back today. I polished the staiunless and also the bronze. Here are a few pics of assembly. Now all i need to do is build a motor assy and tonearm pod and i will be listening on it.

This pic is of the bearing after polishing and i am just about to assemble it.

Attachments

Bearing

From my original thead :

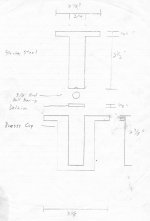

I may still have the drawings if you are intersted let me know will see if i can find them.

Thanks Garry

From my original thead :

So the first thing i did was get a local engenier to make me a bearing i have ended up with a very close copy of the Teres Audio Bearing cost on this came in well under US$80 the outer portion made out of Bronze the inner out of Stainless

I may still have the drawings if you are intersted let me know will see if i can find them.

Thanks Garry

the pods are finished except mounting

Just updating you guys on recent progress on my table.

I have my pods completed, I took thinkwall food grade stainless steel pipe welded a bottom into the motor pod about 1/2 inch up and the machinist came up with threding on the tops, gives a nice clean look. The tonearm pod is half the pipe and the other half is part of a copier drum pressed into this then capped in a simular way. I have a secong lower tonearm pod made and i plan on finishing it when my tonearm is done.

Now all i haver to do is get and install a motor and controller.

Just updating you guys on recent progress on my table.

I have my pods completed, I took thinkwall food grade stainless steel pipe welded a bottom into the motor pod about 1/2 inch up and the machinist came up with threding on the tops, gives a nice clean look. The tonearm pod is half the pipe and the other half is part of a copier drum pressed into this then capped in a simular way. I have a secong lower tonearm pod made and i plan on finishing it when my tonearm is done.

Now all i haver to do is get and install a motor and controller.

Attachments

Re: bearing

Here is my drawing i used. I drew it based on Gazzafloyd 's table and teres a bit.

The machine tachnician made a few modifations to it, he used bronze instead of brass. He also used my previous steel bearing mount and machined the grove out of it and pressed in the bronze. This made it cheaper less matrerial removal time and i had the other one allredy mounted.

Use at your own risk, have fun.

kilowattski said:I am also very interested in your bearing drawing.

GazzaFloyd said:sorry guys i know longer have that drawing

Here is my drawing i used. I drew it based on Gazzafloyd 's table and teres a bit.

The machine tachnician made a few modifations to it, he used bronze instead of brass. He also used my previous steel bearing mount and machined the grove out of it and pressed in the bronze. This made it cheaper less matrerial removal time and i had the other one allredy mounted.

Use at your own risk, have fun.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Completing my DIY TT