Indeed. But how do we set minimal stylus azimuth/SRA error when we don't know the mounting error of the stylus shank on the cantiver? Often that error is profound, IME.I would assume folks would want to be able to do both and make up their own minds.

Apart from microscopic methods, there's only measuring friction coefficient AFAIK. All other methods have minima for generator alignment?

LD

As to eccentricity, will the stamper/drilling error always be the same for all records from this single run ? If so, it can be measured optically and be known. The axis of error can be found relative to a marker in the 3150Hz track. Then auto-correction in polar plot software might remove the error.

As to error from loose fit on spindles, we might make the hole have minimum diameter so as to be tight on most spindles? If it then won't fit some spindles, have some from the run made with a larger diameter, or DIY ream it. Or perhaps do it the other way: have a maximum spec hole and provide a tapered shim ?

LD

As to error from loose fit on spindles, we might make the hole have minimum diameter so as to be tight on most spindles? If it then won't fit some spindles, have some from the run made with a larger diameter, or DIY ream it. Or perhaps do it the other way: have a maximum spec hole and provide a tapered shim ?

LD

That's what I used - to achieve consistent and known speed that isn't necessarily limited to 33/45 rpm and doesn't involve slipping the belt. Soft rubber 'idler' driving the outside of the rim.*actually I had the stupid idea of making a mini Idler I could press against the rim to spin it up.

LD

Soft rubber 'idler' driving the outside of the rim.

I was thinking the angular momentum coming down through a given rpm is the same no matter how high you start from.

Sorry you were ill, I don't remember if you saw my plot of using the Hilbert transform on 20-20k sweep data. It should also work here.

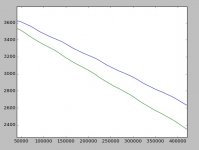

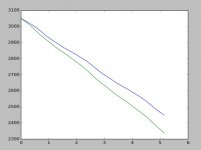

One more plot of the same data aligned and now with time on the x axis.

The top is with tracking force of 1.6gm the bottom with 2.6gm. The plots fit to a polynomial show pretty much a straight line over this range.

Blue - 3050 Hz - 116.7*time Hz + .134*time**2 Hz

Green - 3050 Hz - 137.7*time Hz + .25*time**2 Hz

If these numbers make some sense to anyone I might try to get more of the spin down (what should be the shape of a long one?)

The top is with tracking force of 1.6gm the bottom with 2.6gm. The plots fit to a polynomial show pretty much a straight line over this range.

Blue - 3050 Hz - 116.7*time Hz + .134*time**2 Hz

Green - 3050 Hz - 137.7*time Hz + .25*time**2 Hz

If these numbers make some sense to anyone I might try to get more of the spin down (what should be the shape of a long one?)

Attachments

Last edited:

The eccentricity has never been a priority in record pressing. It could be caused by bad stamper alignment during punching. More likely the problem is the mould tolerances or alignment. Don't forget, this is old technology.

OK, looking for numbers, about a week ago I spoke with an engineer at Viryl Tech and asked about the tolerance for the center spindle to center hole on their new "Warmtone" machine. That is: as the upper and lower molds come together, the center spindle rod comes up through the lower mold center, through the vinyl biscuit and meets the upper mold as it comes down. (Can see it here.) The tolerance of rod to hole is 0.02mm.

Of course Viryl doesn't make stampers as they are a machine manufacturer (the pressing machines) but GZvinyl gives the center to groove eccentricity tolerance for stampers they produce in this paper and it's given as 0.2mm maximum.

On another site I got an advert for these guys the other day Vinyl Carvers | One-off vinyl cutting services | Dubplates

I am exceeding dubious on the quality they can achieve, BUT for £35 it might be worth a punt to try some things out?

I am exceeding dubious on the quality they can achieve, BUT for £35 it might be worth a punt to try some things out?

They only do one-offs. You mean just to try the track ideas out?

As is stands now for the group buy run and being lazy, my ever so convenient armchair fantasizing is that we could contact GZ, tell them about the project enough that their engineer takes a personal interest in seeing if he can get the stampers right on. Then send them to a plant that uses the Warmtone . . . . . unless of course GZ can match Viryl's tolerance . We'd have to ask.

As is stands now for the group buy run and being lazy, my ever so convenient armchair fantasizing is that we could contact GZ, tell them about the project enough that their engineer takes a personal interest in seeing if he can get the stampers right on. Then send them to a plant that uses the Warmtone . . . . . unless of course GZ can match Viryl's tolerance . We'd have to ask.

I am exceeding dubious on the quality they can achieve,

We will always strive to make it as loud as possible.

Just what we need. I'd like to try the spiral 1KHz +- a little track not sure it's worth it by itself but it does not depend on RIAA at all. OTOH a one sided 7" is cheaper

Last edited:

Basically yes. If their quality is good, then there is a way to perhaps get some of the more contentious tracks made that way for the 2 of us who want them  .

.

I think basically everyone is waiting until we have a cutting house lined up and then we can argue the minutae again. No pressure on anyone at all, of course...

As to the 'loud' part I just take that as DJ freeky Phineas sends in his CD of banging beats and they master as hot as they can within their process. I am sure finesse can be shown if requested.

I think basically everyone is waiting until we have a cutting house lined up and then we can argue the minutae again. No pressure on anyone at all, of course...

As to the 'loud' part I just take that as DJ freeky Phineas sends in his CD of banging beats and they master as hot as they can within their process. I am sure finesse can be shown if requested.

From the recent Analog Planet newsletter (and the website) in reference to a recent Rolling Stones vinyl Box Set release:

" ...

Oh, and you'd also want the records to be well-pressed. I received a sealed box to review so no special set (it is box No. 00061). I've heard plenty of grousing about new pressing quality. This set, pressed at MPO in France contained a box of 18 perfectly pressed, perfectly flat records. MPO, which is a "veteran" pressing plant is now producing "world class" records.

..."

The article has some other details that might be of interest to this project.

Read more at:

Righting a Rolling Stones Catalogue Wrong: The New Rolling Stones "Studio Album Collection 1971-2016" Box Set | Analog Planet

" ...

Oh, and you'd also want the records to be well-pressed. I received a sealed box to review so no special set (it is box No. 00061). I've heard plenty of grousing about new pressing quality. This set, pressed at MPO in France contained a box of 18 perfectly pressed, perfectly flat records. MPO, which is a "veteran" pressing plant is now producing "world class" records.

..."

The article has some other details that might be of interest to this project.

Read more at:

Righting a Rolling Stones Catalogue Wrong: The New Rolling Stones "Studio Album Collection 1971-2016" Box Set | Analog Planet

Hand lathe cut 7” might be worth a shot for testing purposes:

Obviously they won’t hold up like standard vinyl but we won’t be requiring that many spins.

Should be a piece of cake to get 5 of us who are chomping at the bit for something tangible to plunk down $20.

Perfect to satisfy ones inner collector scum

5 CT. 7” RECORDS WITH JACKETS

5 stereo 7” records from Austin Signal (5:00 per side max)

Full color 2-sided jackets

Full color center label

Poly-sealed

Total Price: $90

Lathe Cut Vinyl — Austin Signal - Short Run Vinyl, Vinyl On Demand, Analog and Digital Recording in the Hill Country of Austin, Texas

7 CT. 7” RECORDS WITH BLANK JACKETS

7 stereo 7” records from Tangible Formats (6:00 per side max)

Blank white labels

White paper sleeves

10 white cardstock jackets from Amazon

Total price: $94

Prices

Correction: 10 7” from Tangible Formats = $155, probably ~$20 or so ea to everyone’s front door if within the US.

I’d shell out the initial cost and run a 5-10 count Micro-GB if there’s interest.

At least it gives us an opportunity to see where we stand before making a leap.

Obviously they won’t hold up like standard vinyl but we won’t be requiring that many spins.

Should be a piece of cake to get 5 of us who are chomping at the bit for something tangible to plunk down $20.

Perfect to satisfy ones inner collector scum

5 CT. 7” RECORDS WITH JACKETS

5 stereo 7” records from Austin Signal (5:00 per side max)

Full color 2-sided jackets

Full color center label

Poly-sealed

Total Price: $90

Lathe Cut Vinyl — Austin Signal - Short Run Vinyl, Vinyl On Demand, Analog and Digital Recording in the Hill Country of Austin, Texas

7 CT. 7” RECORDS WITH BLANK JACKETS

7 stereo 7” records from Tangible Formats (6:00 per side max)

Blank white labels

White paper sleeves

10 white cardstock jackets from Amazon

Total price: $94

Prices

Correction: 10 7” from Tangible Formats = $155, probably ~$20 or so ea to everyone’s front door if within the US.

I’d shell out the initial cost and run a 5-10 count Micro-GB if there’s interest.

At least it gives us an opportunity to see where we stand before making a leap.

Last edited:

- Home

- Source & Line

- Analogue Source

- Test LP group buy