Until recently I was never that bothered about stylus profiles having lived with an elliptical for nearly 2 decades, but the arrival of an AT150-Mlx, which is one of the most extreme profiles out there has made me start to re-appraise. Like so many things with vinyl there are contradictory viewpoints, some going back decades so no two people can agree upon things like the life expectancy of a stylus or which profile picks up the least noise from a record, or even which one to play worn records with. There is the odd data point, but nothing really measurable or repeatable.

So starting with the premises that

1. The quality and polish of the diamond is the most important thing before the shape

2. HF response goes first when the tip starts to wear.

3. Changes in THD should indicate when a tip is near worn out.

I thought we should be able to test some things and just maybe come up with some sort of quality metrics. Given that, for example Benz micro has gone from elliptical, to Gyger S to microridge over the years in what is basically the same cartridge (their wood series) even the manufacturers seems to sway with the wind.

So 3 premises (or conjectures if you prefer) that need testing, so I'll present my ignorance and see what others think.

Polish: I have no hard evidence, just piles of anecdote. If you look at classic broadcast cartridges such as the DL-102 then they had conicals but nude and well polished. These all seem to have greater than expected lifetime (although AT in their mono-3 do say rather wonderfully "500 hours usage time extending the life span of precious mono recording") and reports seem to be that surface noise is low. At the other extreme ortofon claim 2000 hours expected life for their replicant 100 and some purveyors of the gyger signature profile tout even more.

HF Response: For this I have to rely on some discussions with someone who plays CD4 surround recordings. He used to use Shibata then swapped to the AT microridge, which he said lasted longer, but still after 300 hours would lose the HF FM signal. Not sure the mechanism for this though. But something that can be checked with test records.

THD has started to interest me, ever since someone mentioned that, in comparing the OM40 and ATOC9 cartridges the ortofon had 6dB higher THD. I've asked for the test method and measurements but heard nothing yet. And the reason it interests me is that Jico specify 3% THDat 15kHz being the point at which a stylus is past its best (out of spec) and list the following expected hours to reach this point for different stylus types.

Spherical / Conical - 150hrs

Elliptical - 250hrs

Shibata/Line contact - 400hrs

SAS/MicroRidge - 500hrs

I was excited when someone pointed out this Cartridge reviews has a load of cartridge distortion measurements. Sadly, they are done at 315Hz using the +15dB track so no use in my quest, but interesting to see the spread, with some expensive models being really quite awful (and the OC9 being one of the best). Paul Miller has posted loads of measurements, but the more I look at them, the less I trust them. But there still might be something here.

In the research though I came up with one confusion, which is that in the hi-fi world measurements they show a distinct droop in HF tracking inner grooves. They claim this is due to cartridge resonance, but that doesn't seem to compute. I need to mull that.

At this point I run into the issue that few of us are quite OCD enough to log run hours on a cartridge although I intend to start .

.

Enough waffle from me, what do you think?

So starting with the premises that

1. The quality and polish of the diamond is the most important thing before the shape

2. HF response goes first when the tip starts to wear.

3. Changes in THD should indicate when a tip is near worn out.

I thought we should be able to test some things and just maybe come up with some sort of quality metrics. Given that, for example Benz micro has gone from elliptical, to Gyger S to microridge over the years in what is basically the same cartridge (their wood series) even the manufacturers seems to sway with the wind.

So 3 premises (or conjectures if you prefer) that need testing, so I'll present my ignorance and see what others think.

Polish: I have no hard evidence, just piles of anecdote. If you look at classic broadcast cartridges such as the DL-102 then they had conicals but nude and well polished. These all seem to have greater than expected lifetime (although AT in their mono-3 do say rather wonderfully "500 hours usage time extending the life span of precious mono recording") and reports seem to be that surface noise is low. At the other extreme ortofon claim 2000 hours expected life for their replicant 100 and some purveyors of the gyger signature profile tout even more.

HF Response: For this I have to rely on some discussions with someone who plays CD4 surround recordings. He used to use Shibata then swapped to the AT microridge, which he said lasted longer, but still after 300 hours would lose the HF FM signal. Not sure the mechanism for this though. But something that can be checked with test records.

THD has started to interest me, ever since someone mentioned that, in comparing the OM40 and ATOC9 cartridges the ortofon had 6dB higher THD. I've asked for the test method and measurements but heard nothing yet. And the reason it interests me is that Jico specify 3% THDat 15kHz being the point at which a stylus is past its best (out of spec) and list the following expected hours to reach this point for different stylus types.

Spherical / Conical - 150hrs

Elliptical - 250hrs

Shibata/Line contact - 400hrs

SAS/MicroRidge - 500hrs

I was excited when someone pointed out this Cartridge reviews has a load of cartridge distortion measurements. Sadly, they are done at 315Hz using the +15dB track so no use in my quest, but interesting to see the spread, with some expensive models being really quite awful (and the OC9 being one of the best). Paul Miller has posted loads of measurements, but the more I look at them, the less I trust them. But there still might be something here.

In the research though I came up with one confusion, which is that in the hi-fi world measurements they show a distinct droop in HF tracking inner grooves. They claim this is due to cartridge resonance, but that doesn't seem to compute. I need to mull that.

At this point I run into the issue that few of us are quite OCD enough to log run hours on a cartridge although I intend to start

Enough waffle from me, what do you think?

Would be an interesting experiment to find out what's what.

I'm wondering if increasing noise level might also correlate to stylus wear? (Noting that profile seems to determine how much tracing noise there is to start with)

The important thing I think is to measure the cartridge performance such as distortion and HF response along the way.

I'm now at least using cartridges where I can replace the stylus in the event of a mishap or wear out.

One of the comments I would have on the Jico criteria is how those recommendations are driven by a desire to maintain a healthy stylus renewal business? I've never thought that anything under 1K hours was an issue with cartridges I've owned. (Erm, except for sapphire styli I had in my youth)

I'm wondering if increasing noise level might also correlate to stylus wear? (Noting that profile seems to determine how much tracing noise there is to start with)

The important thing I think is to measure the cartridge performance such as distortion and HF response along the way.

I'm now at least using cartridges where I can replace the stylus in the event of a mishap or wear out.

One of the comments I would have on the Jico criteria is how those recommendations are driven by a desire to maintain a healthy stylus renewal business? I've never thought that anything under 1K hours was an issue with cartridges I've owned. (Erm, except for sapphire styli I had in my youth)

I remember reading online a decade plus ago someone inspected a cartridge under microscope for the baseline, then cleaned the tip after playing each side. After x hours of play (1000?) he re-inspected the tip, and it looked brand new under the scope. He did the same thing with same brand cart without cleaning, and the tip looked ravaged and spent after much less hours than that.

This was at the time when my AT440ML was about 1-2 years old. Since, I've been cleaning the stylus after each record even when the record was cleaned, and after each side when it audibly picked up gunk . It's super sensitive, and it will pick up gunk from brand-new looking records - just play a record 2-3 times to clean it up. Well, just kidding, that's probably the fast way to damage the tip.

Been cleaning records with Nitty Gritty, so the stylus rarely got exposed to really dirty records. Cleaning the stylus with the octanol (other name: capryl alcohol). This is the active ingredient in stylus cleaners, a heavy alcohol that does a great job in dissolving gunk. (And cantilever adhesion if you apply it there - never happened to me ; ) Works much better than isopropanol. (Propanol evaporates too fast for a good cleaning .) Extremely stinky though, and can't buy it over the counter.

That said, I put about 3000 hrs into the AT440ML, and I did not notice any degradation in the sound. When I stopped using it, it sounded at it's peak with fantastic HF extension, mounted on a yard long arm.

The cat jumped on the arm, it lifted two feet high in the air, and then the stylus slammed down onto the marble slab which was under the table. Curiously, the cartridge worked fine after that. I could not hear any change in the sound but I got a replacement nevertheless (AT440MLa) and retired the abused one. (Which has previously suffered some abuse, but not quite like that.)

Curiously, the cartridge worked fine after that. I could not hear any change in the sound but I got a replacement nevertheless (AT440MLa) and retired the abused one. (Which has previously suffered some abuse, but not quite like that.)

The MLa also got super high hours. For the past couple years been using a Grado elliptical, cleaing that rigorously as well, and it's not showing any signs of wear either.

My experience is that when you clean the stylus regularly, there is no stylus wear. And, the AT440s are indestructible - both suffered some extreme rough playing during the years.

I have done no measurements on them though. Just plain listening.

This was at the time when my AT440ML was about 1-2 years old. Since, I've been cleaning the stylus after each record even when the record was cleaned, and after each side when it audibly picked up gunk . It's super sensitive, and it will pick up gunk from brand-new looking records - just play a record 2-3 times to clean it up. Well, just kidding, that's probably the fast way to damage the tip.

Been cleaning records with Nitty Gritty, so the stylus rarely got exposed to really dirty records. Cleaning the stylus with the octanol (other name: capryl alcohol). This is the active ingredient in stylus cleaners, a heavy alcohol that does a great job in dissolving gunk. (And cantilever adhesion if you apply it there - never happened to me ; ) Works much better than isopropanol. (Propanol evaporates too fast for a good cleaning .) Extremely stinky though, and can't buy it over the counter.

That said, I put about 3000 hrs into the AT440ML, and I did not notice any degradation in the sound. When I stopped using it, it sounded at it's peak with fantastic HF extension, mounted on a yard long arm.

The cat jumped on the arm, it lifted two feet high in the air, and then the stylus slammed down onto the marble slab which was under the table.

The MLa also got super high hours. For the past couple years been using a Grado elliptical, cleaing that rigorously as well, and it's not showing any signs of wear either.

My experience is that when you clean the stylus regularly, there is no stylus wear. And, the AT440s are indestructible - both suffered some extreme rough playing during the years.

I have done no measurements on them though. Just plain listening.

It is strange, one would expect less hours for a stylus having sharp edges and smaller contact radius, and more hours for a blunt spherical stylus.Spherical / Conical - 150hrs

Elliptical - 250hrs

Shibata/Line contact - 400hrs

SAS/MicroRidge - 500hrs

I also heard that orientation of the crystal grid of the diamond also matters. True?

Grain orientation is I believe critical and one of the reasons nude diamonds last longer than bonded. Ref the sharp edge, the part you are missing is that the spherical has the smallest contact patch of all and the small minor radius designs have a large major radius, so a much larger contact patch.

Janos: Very true, cleanliness is vital to keep grinding paste out of your grooves. I'm a convert to magic eraser for this job. Ref the life of the AT's the micro-ridge is one of the most extreme profiles and is Maser polished so I would actually expect some of the longest lifetime from that. I have read concern about chipping of the stylus, but not seen any pictures of that happening.

Janos: Very true, cleanliness is vital to keep grinding paste out of your grooves. I'm a convert to magic eraser for this job. Ref the life of the AT's the micro-ridge is one of the most extreme profiles and is Maser polished so I would actually expect some of the longest lifetime from that. I have read concern about chipping of the stylus, but not seen any pictures of that happening.

Probably conical shape has very less contact point area mimicking groove modulation than other stylus profile which were designed to extract as much information as possible by various shapes keeping intimate contact with extreme varying modulation shapes. In other words less contact area more pressure more wear I suppose.It is strange, one would expect less hours for a stylus having sharp edges and smaller contact radius, and more hours for a blunt spherical stylus.

I also heard that orientation of the crystal grid of the diamond also matters. True?

Regards.

When I have looked at my various cartridges under microscope I have not seen anything I can recognize as wear on them, perfectly smooth edges and surfaces on the stylus.

Concials have one tiny dot contacting the groove, much more contact pressure there, thus possibly more wear. Line contact styluses have biggest possible contact surface, wear should be lot lower due to it, and because of the fine geometry they should have no problem tracking the high freqs toward center of the disc where the "wavelength" is 2.6 times shorter for a given freq compared to the edge.

Concials have one tiny dot contacting the groove, much more contact pressure there, thus possibly more wear. Line contact styluses have biggest possible contact surface, wear should be lot lower due to it, and because of the fine geometry they should have no problem tracking the high freqs toward center of the disc where the "wavelength" is 2.6 times shorter for a given freq compared to the edge.

How can vinyl wear out diamond, unless of course, you have airborne diamond dust.

An atom at a time..

Janos: Very true, cleanliness is vital to keep grinding paste out of your grooves. I'm a convert to magic eraser for this job. Ref the life of the AT's the micro-ridge is one of the most extreme profiles and is Maser polished so I would actually expect some of the longest lifetime from that. I have read concern about chipping of the stylus, but not seen any pictures of that happening.

billshurv, thank you for the tip on magic eraser. Didn't know AT tips were Maser polished. Neat! Indeed, it seems that my AT cartridges have not ages at all.

Just received an AT330MONO Anniversary edition a few weeks ago. It has an impossibly tiny tip, smallest I've seen. Barely anything even under a magnifier.

Thought to chip in my 2p worth:So starting with the premises that

1. The quality and polish of the diamond is the most important thing before the shape

2. HF response goes first when the tip starts to wear.

3. Changes in THD should indicate when a tip is near worn out.

I think that's generally true, except No2: strictly it's programme slew rate that might be limited as stylus radius increases with wear, and that's not quite the same thing as HF response because it physically depends on level and radius too.

Slew rate maps on to groove curvature , which maps on to acceleration, which is hard limited in cutting AFAIK to protect cutter heads and make traceable grooves. So, in practice, No2 might not show up in real programme material at all.

Put another way, any advantage due to stylus profile is gone after about 500 hours if that's true...........Jico specify 3% THDat 15kHz being the point at which a stylus is past its best (out of spec) and list the following expected hours to reach this point for different stylus types.

Spherical / Conical - 150hrs

Elliptical - 250hrs

Shibata/Line contact - 400hrs

SAS/MicroRidge - 500hrs

Besides, it matters at what level and radius the 15kHz tone is recorded.

One can't hear harmonic distortion at 15kHz, BTW: can't tell difference between square and sines even in principle .......... THD just shows up as suppression of the fundamental, a drop in level, and one would be hard pressed to detect 3% level shift....that's 0.25dB..........(!)

Even on an outer radius 15kHz@-25dB ref 5.6cm/s incurs about 2.5 % 2nd harmonic distortion due to pinch effect for a 18um radius stylus, or about 1% for a 7um radius..........

I don't think those published figures/conditions are particularly meaningful or helpful....

LD

Yup, the search for the grail of something universally applicable is quite possibly the undoing.........I agree that the published figures are not particularly helpful, but I've not found anything that is. Maybe there just isn't something universally applicable!

Nevertheless, I think there are 2 missing factors concerning the audible effect of wear that might just underpin a universal explanation:

1. As all profiles wear, a stylus sits lower in the groove than intended, whilst maintaining much the same nominal contact points on the groove walls. This needs some thinking about, but it's true - a stylus effectively slides downward. So stylus base clearance is reduced, perhaps incurring a surface noise penalty as there might be contact between groove base and stylus base.

2. The effect of wear to increase stylus-groove friction, due to flattened profile and development of sharper leading edges. The upshot of which being reduced trackability and increased surface noise, particularly on difficult to track programme content such as sibilance.

I think these two factors might be the ones to explore, especially since AFAIK they aren't generally discussed.......

LD

Hmm, Couple of days ago someone claimed that Microridge would wear flat over time. I did point out that the stylus would be bouncing along the bottom of the groove long before that happened but hadn't considered if for other profiles. But certainly on Ray's stylus shots thread on VE you can see that well worn conicals end up developing a teardrop flat over time which of course is what we would expect.

Has your OM40 got enough hours on to compare to a fresh one when I finally get around to buying one?

Has your OM40 got enough hours on to compare to a fresh one when I finally get around to buying one?

Over 10 years inspecting customer's styli with a decent optical microscope, I saw exactly two with observable wear flat-spots. Several hundred inspected at the very least.... Saw plenty of damaged cantilevers, missing points, etc, but true wear was extremely rare. Yes, many needed careful cleaning. That was the most common issue, built up gunk.

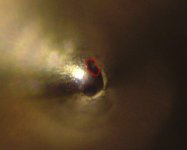

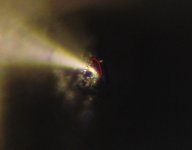

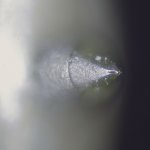

I have some of my own archive shots of wear flat development, for a spherical V500 and a FG OM40. Attached below, with the lesion marked up in red outline.Hmm, Couple of days ago someone claimed that Microridge would wear flat over time. I did point out that the stylus would be bouncing along the bottom of the groove long before that happened but hadn't considered if for other profiles. But certainly on Ray's stylus shots thread on VE you can see that well worn conicals end up developing a teardrop flat over time which of course is what we would expect.

Has your OM40 got enough hours on to compare to a fresh one when I finally get around to buying one?

Very difficult to see and photograph using optical methods: in fact the resolution isn't adequate to see any detail, dimensions being much shorter than wavelength of light.

These styli are still very serviceable, without degradation.

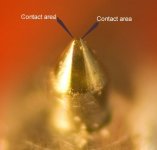

One has to be careful interpreting images of some so called sphericals and ellipticals: there can be intentional flats cut into front and rear, which to the untrained eye might be misinterpreted as wear lesions. These are big enough to be visible and 'glint', and I suspect often the cause of misinterpretation.

I haven't seen Ray's images, if someone cares to post a few of them here, I'd be interested to see and comment?

As to wear as a cause of stylus base fowling, for a spherical base clearance is perhaps nominally ~5um in reality. Each µm depth of flat wear reduces clearance by ~3µm, so it seems plausible as a cause of performance degradation, especially surface noise, IMO.

I subscribe to a view that, instantaneously, stylus-groove contact locations are effectively very small regions on the stylus which move around within a larger 'possible' contact region depending on instantaneous groove shape.

IMO, the whole wear lesion is probably an accumulated wear pattern of instantaneous locations, and doesn't make contact in whole with the wall at once. It develops the characteristic teardrop shape partly from shift in instantaneous contact locus, and partly from a stylus progressively sitting lower in the groove as it wears.

Also attached is an image of a bonded elliptical showing the difference between intentional flat cuts and contact locations.

LD

Attachments

Last edited:

Ok here is one. Photobucket has really gone downhill. Ray's focus stacking works really well here, and with pixel counting you can get an idea of the wear. Second pic is a real basket case. third picture is not as bad but still worn out

Attachments

Last edited:

How can vinyl wear out diamond, unless of course, you have airborne diamond dust.

Remember that wear due to friction always is a bilateral affair.

Best regards!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Stylus wear measurement