Hi All....

I just picked up a Dual 1229 that is mechanically good and could do with a little TLC.

Anyone familiar with the little attachment on the deck just behind the tonearm support? It is not screwed onto the deck, and looks like there may be a couple of 1/16" thick adhesive pads attaching it. I am not familiar with Dual products-this is my first, and I have not seen one of these things on any other 1229s.

Thanks

Peter

I just picked up a Dual 1229 that is mechanically good and could do with a little TLC.

Anyone familiar with the little attachment on the deck just behind the tonearm support? It is not screwed onto the deck, and looks like there may be a couple of 1/16" thick adhesive pads attaching it. I am not familiar with Dual products-this is my first, and I have not seen one of these things on any other 1229s.

Thanks

Peter

Attachments

Anyone familiar with the little attachment on the deck just behind the tonearm support?

It's some kind of third party product, like a stylus brush, etc.

Just move the arm out of the way and pull it off. It's held on by adhesive pads.

Thank you guys.

Be sure to remove the headshell before you start working on this.

Thanks for the helpful suggestions. This is going to be a lengthy project. Currently making a heavy oak plinth and polishing the dust cover after trimming it down to just clear the counterweight. Not interested in stacking lps and the only auto feature I care for is the tonearm return. Just in case I fall asleep.

Currently making a heavy oak plinth and polishing the dust cover after trimming it down

to just clear the counterweight.

The counterweight will move backward or forward depending on the weight of the cartridge installed.

If you change the cartridge, the position of the counterweight will likely change.

The Dual 1229 is a very fine turntable, most probably one of the best idler wheel driven TT's ever made. I love it dearly and own four of them in completely serviced, full functional state and several more just for parting out.

Due to it's delicate mechanics, a complete "TLC" may mean several hours of work. Rather often the motor has become noisy and needs to be relubricated, which means a complete dissassembly in order to get access to the lower shaft bearing. Once opened, I usually swap the upper and the lower bearing and als swap the small metal disc the rotor shaft sits on. Be careful not to crack the shaft while removing the end bells! Hope the speed selector and the so called Multi Selector levels in the left front corner and at the tonearm base, respectively, aren't stuck? Then don't try to force them, as somewhat will (!) break (one of mine had a broken speed lever, due to it's stuck internal mechanism, which I had to replace by the lever and some more components of it's precedessor 1219). Instead service them!

You will find the original Dual Service Manual and some more helpful hints from others in the WWW.

As yet said, the thing at your pics is a strange item and not original.

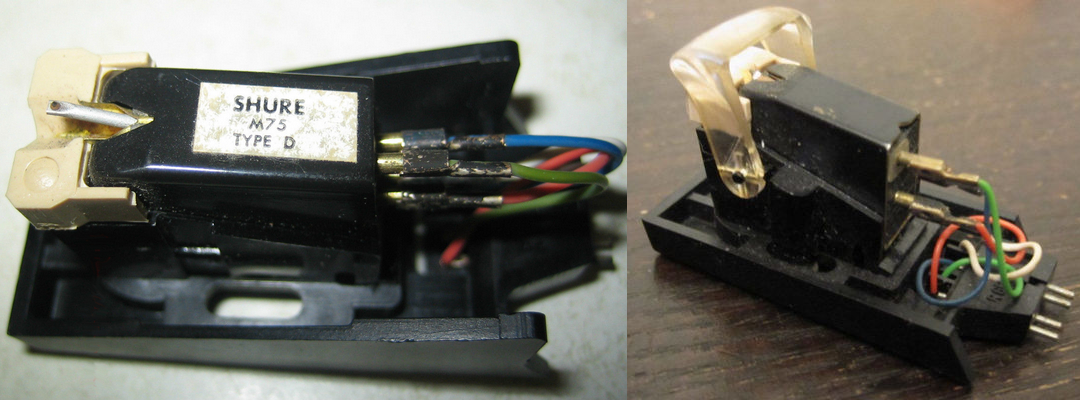

Btw, at least according to your pics your 1229 lacks the proprietary Dual TK14 cartridge adaptor which is a black plastic thing that carries the cart and needs to be attached to the headshell by two 45 degrees' moves (first backward, second forward) of the small handle. Here's a picture showing two Shure M75's sitting on Dual TK's. The left one is the TK14 the 1229 originally came with. But the right one, a TK24, will also fit and still can be purchased as NOS from specialized vendors:

You really don't need to dissasselble the empty headshell prior to removing your strange thing. Instead, I'd strongly advice you not to try it, as this means some real challenge.

Best regards!

Due to it's delicate mechanics, a complete "TLC" may mean several hours of work. Rather often the motor has become noisy and needs to be relubricated, which means a complete dissassembly in order to get access to the lower shaft bearing. Once opened, I usually swap the upper and the lower bearing and als swap the small metal disc the rotor shaft sits on. Be careful not to crack the shaft while removing the end bells! Hope the speed selector and the so called Multi Selector levels in the left front corner and at the tonearm base, respectively, aren't stuck? Then don't try to force them, as somewhat will (!) break (one of mine had a broken speed lever, due to it's stuck internal mechanism, which I had to replace by the lever and some more components of it's precedessor 1219). Instead service them!

You will find the original Dual Service Manual and some more helpful hints from others in the WWW.

As yet said, the thing at your pics is a strange item and not original.

Btw, at least according to your pics your 1229 lacks the proprietary Dual TK14 cartridge adaptor which is a black plastic thing that carries the cart and needs to be attached to the headshell by two 45 degrees' moves (first backward, second forward) of the small handle. Here's a picture showing two Shure M75's sitting on Dual TK's. The left one is the TK14 the 1229 originally came with. But the right one, a TK24, will also fit and still can be purchased as NOS from specialized vendors:

You really don't need to dissasselble the empty headshell prior to removing your strange thing. Instead, I'd strongly advice you not to try it, as this means some real challenge.

Best regards!

Great stuff!

The turntable is a one owner, and has been in a closet for many years. I was told that mechanically, it functions. The UA base is awful, not even square and it has already gone.

The black acrylic dust cover is being wet sanded with 1000-2000 grit and will be polished.

I did power the turntable when I got it home, after trying to index the auto mechanism by locking the tonearm, placing the switch to the start position and turning the platter by hand.

The start switch did not move to the stop position.

The motor seems dead quiet. The only sound I heard was the swooshing of the paper disk partly attached to the underside of the platter. The C clip is missing from the top of the spindle housing. All switches move reasonably well,including the tonearm height selector.

Here is a picture of the cartridge carrier that came with it, with an AT TM7 mounted.

Many thanks

Peter

The turntable is a one owner, and has been in a closet for many years. I was told that mechanically, it functions. The UA base is awful, not even square and it has already gone.

The black acrylic dust cover is being wet sanded with 1000-2000 grit and will be polished.

I did power the turntable when I got it home, after trying to index the auto mechanism by locking the tonearm, placing the switch to the start position and turning the platter by hand.

The start switch did not move to the stop position.

The motor seems dead quiet. The only sound I heard was the swooshing of the paper disk partly attached to the underside of the platter. The C clip is missing from the top of the spindle housing. All switches move reasonably well,including the tonearm height selector.

Here is a picture of the cartridge carrier that came with it, with an AT TM7 mounted.

Many thanks

Peter

Attachments

The start switch did not move to the stop position.

This usually means the need of a complete cleaning and relubrication. Or the small plastic cap is missing that serves as a friction clutch between teh so called main lever and the lower section of the tonearm base.

The only sound I heard was the swooshing of the paper disk partly attached to the underside of the platter. The C clip is missing from the top of the spindle housing.

This paper ring has a printing of stroboscopic markings. It should be sticking flat at the platter's underside. Does the neon strobe lamp glow? They often fail after four decades, original parts are gone for a long time, but there are LED based replacements.

Best regards!

Your comments are really appreciated. This is my first look at a Dual.

The mechanisms appear to be very clean. No plier marks anywhere and at first glance, little evidence of grease, dried or otherwise.

Besides the start/stop switch situation I mentioned earlier, the cuing lever has difficulty staying in the up position and springs back 9 times out of 10.

You mention a plastic part. There is precious little plastic anywhere. If needed, are the plastic bits available, or do I need to be creative in a diy sense?

Peter

The mechanisms appear to be very clean. No plier marks anywhere and at first glance, little evidence of grease, dried or otherwise.

Besides the start/stop switch situation I mentioned earlier, the cuing lever has difficulty staying in the up position and springs back 9 times out of 10.

You mention a plastic part. There is precious little plastic anywhere. If needed, are the plastic bits available, or do I need to be creative in a diy sense?

Peter

The plinth is mostly done. Just need to decide whether to cut some Linn style grooves around perimeter.

I polished the cartridge mating contacts and in manual mode it works great. Sounds quite different to my heavily upgraded(all diy) LP12. The dual sounds silky smooth and tracks superbly with the AT tm7.

I polished the cartridge mating contacts and in manual mode it works great. Sounds quite different to my heavily upgraded(all diy) LP12. The dual sounds silky smooth and tracks superbly with the AT tm7.

Attachments

That's what I said, Peter  !

!

These old Dual TT's most probably are very underrated.

Have a look at this document. The pics at page 19 and the 2nd one at page 20 show the small amber coloured plastic cap I've mentioned before, which isn't a cap anymore here . It is a tiny piece of plastic, about 3 mm each in diameter and height, and serves as a friction clutch to move the tonearm. Most probably your's is gone or defective as well. I usually replace them with a piece of the inner insulator of some coaxial cable after having widened the bore at one of both sides.

. It is a tiny piece of plastic, about 3 mm each in diameter and height, and serves as a friction clutch to move the tonearm. Most probably your's is gone or defective as well. I usually replace them with a piece of the inner insulator of some coaxial cable after having widened the bore at one of both sides.

Best regards!

These old Dual TT's most probably are very underrated.

Have a look at this document. The pics at page 19 and the 2nd one at page 20 show the small amber coloured plastic cap I've mentioned before, which isn't a cap anymore here

Best regards!

I'd owned at least 6 different models of Duals between 1968 and approx '82, and except for the bottom end machines that were part of "consolette" record players, they always just worked, and the sound was dependent on the phono cartridge*. I never actually used the stacking feature after the first model. Come to think of it, while I was engaged in the retail business off and on for a few years between 72 and 98, and certainly sold lots of brands of 'tables, I don't think I ever owned anything other than a Dual automatic - lots of manuals, though.

Yup, the idler drive models from 1219 forward until the 600 and 700 series belt and direct drives were woefully underrated. Looking at the repair / service document linked above, it's amazing these almost Rube Goldberg machines worked at all, much less for 40+ yrs.

*My favorite was the 701 with Decca London MkV - talk about dynamics and detail. Good thing the preamp stage of Yamaha amp had a decent LF filter - even slight warped records got the woofers and passive radiators on Ditton 66's hopping around more than a little bit.

Yup, the idler drive models from 1219 forward until the 600 and 700 series belt and direct drives were woefully underrated. Looking at the repair / service document linked above, it's amazing these almost Rube Goldberg machines worked at all, much less for 40+ yrs.

*My favorite was the 701 with Decca London MkV - talk about dynamics and detail. Good thing the preamp stage of Yamaha amp had a decent LF filter - even slight warped records got the woofers and passive radiators on Ditton 66's hopping around more than a little bit.

"Rube Goldberg" came to mind when I first looked under the deck. He must have been a German.

With a lot of experience restoring British sports cars of the 50s and 60s, maybe it is a Eurpean affliction to use twice as many components as are necessary to get the job done.

I don't doubt that all the parts in the 1229 are necessary to be fully automated, but when all I want to do is listen to music, one disc at a time, there sure seems like a lot going on under the deck.

In the final analysis, the proof is in the listening, and it ranks pretty high on my list. It is a far cry from my first turntable, a Gerrard SP25. Remember those?

With a lot of experience restoring British sports cars of the 50s and 60s, maybe it is a Eurpean affliction to use twice as many components as are necessary to get the job done.

I don't doubt that all the parts in the 1229 are necessary to be fully automated, but when all I want to do is listen to music, one disc at a time, there sure seems like a lot going on under the deck.

In the final analysis, the proof is in the listening, and it ranks pretty high on my list. It is a far cry from my first turntable, a Gerrard SP25. Remember those?

Strange you should mention the lesser Duals. I have been given a 1242 that needs some work. The tonearm seems very sluggish in the vertical mode and I am unable to balance it.

Also, after being plugged in for a few minutes, after starting and stopping with the switches, the platter will turn on its own. Maybe the start switch or capacitor? This one is on the back burner.

Peter

Also, after being plugged in for a few minutes, after starting and stopping with the switches, the platter will turn on its own. Maybe the start switch or capacitor? This one is on the back burner.

Peter

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Dual 1229 question