Another option would be to seal off the rubber and drop lead pellets with 5 minute epoxy into the U channel.

You might get 3 or so in there, anything to add mass along with sorbothane to couple to the body.

I have 3 cartridges and 4 replacement stylus assemblies and will try this mod next

Do not under estimate the forces going on with a cartridge !

If you could shrink yourself down to fit in a groove next to the diamond, it would be a incredible violent world so anything you can do to tame its environment will pay off in sonic dividends.

Regards

David

I like the lead sheet idea. If any one want a small piece of 1.5 mm lead sheet, please pm me. I tried 1.5 mm lead sheet on my 451C. It is a little thick, but if you can sand it or hammer it slightly, it will fit perfectly into the channel.

Without a full on redesign and new build,

I think machining a single block (matching the original dimensions) to take all the existing components, improving it a bit with a screwed down "V" shaped strain beam plate and include some way to firmly mount/screw down the existing plastic red stylus carriers.

Piece of cake!

The existing black plastic body being hollow seems to offer no good place to put screws through the red carrier up into the body. A more solid recreation may be able to solve that.

Some way to re-route the wires from the strain gauges will be needed so much area can remain solid.

Having the area above all of that flat so it could be bonded to different materials is easy.

Personally I think making it just plain heavy will be enough.

Regarding the side ways movement for alignment of the stylus carrier...I think that is correcting a problem that should not be there with proper fitting parts and assembly. Incorporating a few thousandths of side ways play would be easy though.

All (most) of the true Panasonic old stock stylus assemblies I have seen seem to have pretty good centering. I assume the problem ones are caused by the slightly off sized red carriers or problems with assembly jigs or just lack of attention to detail during assembly.

Also I would think adjusting the stylus carrier to one side to center up the cantilever would be pre-loading one channel of the entire donut/strain beam system.

For the Soundsmith stylus units...are they aluminum? Is the blue stuff just holding in some steel to work with the magnet? I have never seen the Soundsmith in person.

The more I consider all of this I myself will probably just stick to resonance control and increasing the mass of an existing body.

I think machining a single block (matching the original dimensions) to take all the existing components, improving it a bit with a screwed down "V" shaped strain beam plate and include some way to firmly mount/screw down the existing plastic red stylus carriers.

Piece of cake!

The existing black plastic body being hollow seems to offer no good place to put screws through the red carrier up into the body. A more solid recreation may be able to solve that.

Some way to re-route the wires from the strain gauges will be needed so much area can remain solid.

Having the area above all of that flat so it could be bonded to different materials is easy.

Personally I think making it just plain heavy will be enough.

Regarding the side ways movement for alignment of the stylus carrier...I think that is correcting a problem that should not be there with proper fitting parts and assembly. Incorporating a few thousandths of side ways play would be easy though.

All (most) of the true Panasonic old stock stylus assemblies I have seen seem to have pretty good centering. I assume the problem ones are caused by the slightly off sized red carriers or problems with assembly jigs or just lack of attention to detail during assembly.

Also I would think adjusting the stylus carrier to one side to center up the cantilever would be pre-loading one channel of the entire donut/strain beam system.

For the Soundsmith stylus units...are they aluminum? Is the blue stuff just holding in some steel to work with the magnet? I have never seen the Soundsmith in person.

The more I consider all of this I myself will probably just stick to resonance control and increasing the mass of an existing body.

On 2 samples of replaceable stylus assemblies I have , they are slightly angled and you must always align the cantilever beam when finding your 2 null points on the arc. The body is not being aligned

This is not a balanced way to be pressing in on the beams with tracking force and the body/ elements angled.

This condition leads to unequal forces.

Being able to move the attachment point of the cantilever left or right automatically puts equal pressure on the elements as this is now the adjustable fulcrum point for the whole cartridge and tonearm mass. If you think about it , this is the only way to get equal pressure on the 2 sides of each.

What might lead to unequal forces generated would be if the "V" of the strain elements were not parallel to the record surface, but from what I have seen under the microscope , this seems to be consistently decent on my samples

Regards

David

This is not a balanced way to be pressing in on the beams with tracking force and the body/ elements angled.

This condition leads to unequal forces.

Being able to move the attachment point of the cantilever left or right automatically puts equal pressure on the elements as this is now the adjustable fulcrum point for the whole cartridge and tonearm mass. If you think about it , this is the only way to get equal pressure on the 2 sides of each.

What might lead to unequal forces generated would be if the "V" of the strain elements were not parallel to the record surface, but from what I have seen under the microscope , this seems to be consistently decent on my samples

Regards

David

Last edited:

Hi Avwerk,

"Being able to move the attachment point of the cantilever left or right automatically puts equal pressure on the elements as this is now the adjustable fulcrum point for the whole cartridge and tonearm mass"

I agree with your above comment, but after looking at all the stylus examples I have last night I think you need to add more dimensions to the movement....rotation and up and down in relation to the strain beams.

The hinge point needs to be a sphere that can move up, down, front and back and rotate and tilt.

One example I have is glued in at an angle at the base. It needs to twist, then move side ways, alot, easily 30 or 40 thousandth, and then will need to go up or down and front or back to get it right.

That example needs to be reassembled correctly. Most are better but I do not have that many samples.

It is interesting there is a note on the Soundsmith site with regards to buying replacment stylus's that they are fitted to each cartridge. I am sure his assembly tolerances are many magnitudes better than the original parts and he still sees an advantage to custom fitting each one.

Also I may see different alignments of the stylus in relationship to the bottom of the Soundsmith cartridges if I look closely at all the pictures in a google image search.

Dave

"Being able to move the attachment point of the cantilever left or right automatically puts equal pressure on the elements as this is now the adjustable fulcrum point for the whole cartridge and tonearm mass"

I agree with your above comment, but after looking at all the stylus examples I have last night I think you need to add more dimensions to the movement....rotation and up and down in relation to the strain beams.

The hinge point needs to be a sphere that can move up, down, front and back and rotate and tilt.

One example I have is glued in at an angle at the base. It needs to twist, then move side ways, alot, easily 30 or 40 thousandth, and then will need to go up or down and front or back to get it right.

That example needs to be reassembled correctly. Most are better but I do not have that many samples.

It is interesting there is a note on the Soundsmith site with regards to buying replacment stylus's that they are fitted to each cartridge. I am sure his assembly tolerances are many magnitudes better than the original parts and he still sees an advantage to custom fitting each one.

Also I may see different alignments of the stylus in relationship to the bottom of the Soundsmith cartridges if I look closely at all the pictures in a google image search.

Dave

Adjustment in all axis I agree. The depth of the pivot point can be done with shims and left, right ,front , back with elongated holes and machine screws.

I even called Sound Smith and asked the price of the replacement tips (750$-950$) only ruby cantilevers , no boron 😡 (tip profiles differ)

as I contemplated buying one and making the rest , but the price is too steep now.

I think he requires the cart back when choosing the last most expensive version only.

Those adjustments on the side are not user friendly and his. Looks like it moves the elements sideways but not completely sure. The second screw no idea.

Other than the slight angle on a couple stock stylus tips , all 4 of them when pressed in have the same distance away from the body when tracking (2.6 grams for now) so consistency there is ok on mine.

I did notice on the shibata versions the SRA seems to upright requiring a tonearm base to be raised more than typical.

Regards

David

I even called Sound Smith and asked the price of the replacement tips (750$-950$) only ruby cantilevers , no boron 😡 (tip profiles differ)

as I contemplated buying one and making the rest , but the price is too steep now.

I think he requires the cart back when choosing the last most expensive version only.

Those adjustments on the side are not user friendly and his. Looks like it moves the elements sideways but not completely sure. The second screw no idea.

Other than the slight angle on a couple stock stylus tips , all 4 of them when pressed in have the same distance away from the body when tracking (2.6 grams for now) so consistency there is ok on mine.

I did notice on the shibata versions the SRA seems to upright requiring a tonearm base to be raised more than typical.

Regards

David

On a side note.

A dear departed friend of mine had a very rare Stax Electostatic cartridge, came with it's own massive tune-able powersupply, you had to use an oscilloscope to tune it in, took like 20mins and stayed in tune for around 20mins till the humidity changed just a little.

It was mounted in a Infinity Black Widow arm on a Linn Sondek and was the best vinyl replay I had ever heard.

Play through my 100w Pure class A water cooled poweramp through double stacked quad 57's Kelly Decca Ribbons and 24" Hartley's mounted in the wall with the next room as the box.

https://www.vinylengine.com/turntab...e.php?mode=medium&album_id=662&image_id=11682

Cheers George

A dear departed friend of mine had a very rare Stax Electostatic cartridge, came with it's own massive tune-able powersupply, you had to use an oscilloscope to tune it in, took like 20mins and stayed in tune for around 20mins till the humidity changed just a little.

It was mounted in a Infinity Black Widow arm on a Linn Sondek and was the best vinyl replay I had ever heard.

Play through my 100w Pure class A water cooled poweramp through double stacked quad 57's Kelly Decca Ribbons and 24" Hartley's mounted in the wall with the next room as the box.

https://www.vinylengine.com/turntab...e.php?mode=medium&album_id=662&image_id=11682

Cheers George

It would be interesting to see a schematics and construction details of the Stax.

This was reviewed I believe in the Absolute Sound magazine way way back. Could be wrong.

I use similiar components Quads, Vandersteen sub, 100 class A monos

I purchased 2 pairs of 57,s with the intent to stack them also but reasoned time alignment would suffer and I don't listen loud anyway.

Quads do downward dynamic range like no other speaker. You just don't need extreme loudness with these.

Just purchased 988,s and one needs work, so these are being modded and reworked for comparisons sake.

Kevin's circuit sounds so good and has plenty of gain your light speed attn. would be a perfect match

Regards

David

This was reviewed I believe in the Absolute Sound magazine way way back. Could be wrong.

I use similiar components Quads, Vandersteen sub, 100 class A monos

I purchased 2 pairs of 57,s with the intent to stack them also but reasoned time alignment would suffer and I don't listen loud anyway.

Quads do downward dynamic range like no other speaker. You just don't need extreme loudness with these.

Just purchased 988,s and one needs work, so these are being modded and reworked for comparisons sake.

Kevin's circuit sounds so good and has plenty of gain your light speed attn. would be a perfect match

Regards

David

I doubt for people actually able to afford one of these new with one of the matching (and not optional) pre-amps, that the cost of the replacement stylus is a big deal. Even as prohibitive as it seems it is relatively inexpensive compared to an exchange of an Ortofon Windfeld for a new one. (Ortofon does not retip, and does not recommend their cartridges be retipped, although it is quite common) I have a Windfeld and an SPU A95 so some day I face this prospect with both.

I have an A90 in pretty good condition and love it. One thing I complain about is the stylus guard. The guard is not well designed. So I bought a guard for A 95. The new stylus guard is better but it is still not too good. Ortofon charges USD$2,200 for the service of PW and above. They say they don’t re-tip. They change the whole motor and stylus.

It would be interesting to see a schematics and construction details of the Stax.

This was reviewed I believe in the Absolute Sound magazine way way back. Could be wrong.

I use similiar components Quads, Vandersteen sub, 100 class A monos

I purchased 2 pairs of 57,s with the intent to stack them also but reasoned time alignment would suffer and I don't listen loud anyway.

Quads do downward dynamic range like no other speaker. You just don't need extreme loudness with these.

Just purchased 988,s and one needs work, so these are being modded and reworked for comparisons sake.

Kevin's circuit sounds so good and has plenty of gain your light speed attn. would be a perfect match

Regards

David

All I cloud find quickly was this, looks like there was a couple of models.

Freq. Response: 10-40kHz; 10-50kHz for Type2

Channel Separation: 22db(1kz); 24db for Type2

Effective Tip Mass: 0.3mg

Compliance: vetical - 10

horizontal - 20; 15 for Type2

Optimum Tracking Pressure: 1 g.

Stylus shape: 0.2 x 0.8 mil; 0.3 x 0.8 for Type2

Vertical Tracking Angle: 15 degrees

Weight: 9.5g; 8.5g for Type2

And these link to some good pics.

The Rare Stax CPY/ECP-1 electrostatic phono cartridge & equalizer | Audiokarma Home Audio Stereo Discussion Forums

Stax CP-X Electrostatic Direct Pickup System - Vinyl Engine

Cheers George

Attachments

Last edited:

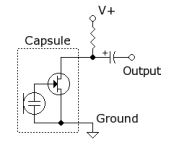

Super rare for sure.. Operating principles are not at all similar to the strain gauges I designed this pre-amp for. I need to research this further, but in thinking about it I suspect an electret/capacitive transducer is in fact velocity sensitive so very, very different than the displacement sensitive strain gauges.

Edit: Well it actually ppears to be displacement sensitive with surprises me a bit based on comments in the Audiokarma thead. There are a couple of jfets in the cartridge body as well which at least one person recommends be replaced.

The current phono pre-amplifier design has very rudimentary EQ which puts it into the realm of reasonably correct if not what I would call precise RIAA equalization. I'm actually working on something that is theoretically a slight improvement. My experience so far is that everything that looks like a theoretical improvement in fact has proved not to be.

There are a couple of optical "strain gauge" cartridges that have appeared on the market over the past year or so:

DS-Audio

Phaedrus

So far I only know of three people besides myself who have either built or are in the process of building the pre-amps. None of the others have posted here about what they are doing which concerns me because I expect both questions to arise and mistakes to occur in the building in at least some instances.

Edit: Well it actually ppears to be displacement sensitive with surprises me a bit based on comments in the Audiokarma thead. There are a couple of jfets in the cartridge body as well which at least one person recommends be replaced.

The current phono pre-amplifier design has very rudimentary EQ which puts it into the realm of reasonably correct if not what I would call precise RIAA equalization. I'm actually working on something that is theoretically a slight improvement. My experience so far is that everything that looks like a theoretical improvement in fact has proved not to be.

There are a couple of optical "strain gauge" cartridges that have appeared on the market over the past year or so:

DS-Audio

Phaedrus

So far I only know of three people besides myself who have either built or are in the process of building the pre-amps. None of the others have posted here about what they are doing which concerns me because I expect both questions to arise and mistakes to occur in the building in at least some instances.

I had no issues first time turn on and with burn in and adjustments.

The only issue is leaving it on over night and one 6C3N-eb going bad with some nasty D.C. Thumps thinking it was the headshell connection.

Other than that , no issues and a straight forward build. Your instructions were spot on.

You must be using a passive or extremely low gain pre and traditional line stages and might need R 10-11 shift points adjusted for more range from a bigger build audience down the road. IMHO

Your circuit brings out any small changes to the cartridge end showing a detailed transparent circuit design.

It was easy to hear the stiffer mod to the u channel cantilever post. The sound stage pushed slightly back with more depth layering and imaging of each instrument tightened up with more focus. Female voice outlines became the size of a real person in space.

I am just getting started and haven't even tranfered to my SLT arm yet , taking advantage of testing with removable headshells to find the one worthy enough to transfer over and finding one for an autopsy and new stiffer housing.

You really did an exceptional circuit design for this cartridge.

2 big thumbs up here !

Regards

David

The only issue is leaving it on over night and one 6C3N-eb going bad with some nasty D.C. Thumps thinking it was the headshell connection.

Other than that , no issues and a straight forward build. Your instructions were spot on.

You must be using a passive or extremely low gain pre and traditional line stages and might need R 10-11 shift points adjusted for more range from a bigger build audience down the road. IMHO

Your circuit brings out any small changes to the cartridge end showing a detailed transparent circuit design.

It was easy to hear the stiffer mod to the u channel cantilever post. The sound stage pushed slightly back with more depth layering and imaging of each instrument tightened up with more focus. Female voice outlines became the size of a real person in space.

I am just getting started and haven't even tranfered to my SLT arm yet , taking advantage of testing with removable headshells to find the one worthy enough to transfer over and finding one for an autopsy and new stiffer housing.

You really did an exceptional circuit design for this cartridge.

2 big thumbs up here !

Regards

David

Thanks Dave! I just saw your comments. This is definitely one of my more worthwhile endeavors, and I am delighted that people like you were willing to trust me at my word about the quality of this design, and fork over significant money for the boards and power transformers even at cost. Factor in the cost of the many other parts and the cartridge(s) it's not a modest investment particularly in the case of the many participants here, none of whom except GTHICM and Shooter know me personally or have presumably heard any of my designs.

My original intention was to try and recoup some of my investment in the original set of PCBs. I never imagined that 22 more sets of boards would go out the door as result of my sharing the design and my journey.

So thank you again, it means a lot..

In all fairness Panasonic created a monster and then apparently dropped the ball, this cartridge technology could have been the ascendant cartridge technology regardless of whether Quad and CD-4 were commercially successful. Instead it became a dead end and a curiosity for people like me to explore. I was pretty dismissive based on the existing commercial examples I heard, particularly given their relatively stratospheric price point.

I had the opportunity to hear a vintage Panasonic strain gauge cartridge under much more favorable conditions on my last visit to Dallas (home of a very vibrant tube diy culture btw), and received several with a challenge to figure out how to make them sound really good. I was not sure it was possible, but it looked like fun.

My goal was something simple and relatively inexpensive which nonetheless did not cut corners in terms of performance capability. Since it was for me and since my system comfortably accommodates sources with relatively high output levels (I design for 2V + sources) the high gain was not an issue.

SNR was sort of important (as you might gather from the performance of your unit) since I use high efficiency speakers with pretty extended LF response and everything else is also very quiet, so it was critical in my mind that it be quiet.

Tradeoffs were made, apparently I will need to figure out how to reduce the gain further for those who need less. (It's excessive for my needs too, I run mine on the -6dB gain tap.) I made no effort to invert one amplifier channel relative to the other because I don't need to do so. My plan was to recommend transformer coupling for those who need to invert or want balanced outputs. Logically a transformer with 2:1 or even 4:1 step down could be useful for those wanting less gain.

My original intention was to try and recoup some of my investment in the original set of PCBs. I never imagined that 22 more sets of boards would go out the door as result of my sharing the design and my journey.

So thank you again, it means a lot..

In all fairness Panasonic created a monster and then apparently dropped the ball, this cartridge technology could have been the ascendant cartridge technology regardless of whether Quad and CD-4 were commercially successful. Instead it became a dead end and a curiosity for people like me to explore. I was pretty dismissive based on the existing commercial examples I heard, particularly given their relatively stratospheric price point.

I had the opportunity to hear a vintage Panasonic strain gauge cartridge under much more favorable conditions on my last visit to Dallas (home of a very vibrant tube diy culture btw), and received several with a challenge to figure out how to make them sound really good. I was not sure it was possible, but it looked like fun.

My goal was something simple and relatively inexpensive which nonetheless did not cut corners in terms of performance capability. Since it was for me and since my system comfortably accommodates sources with relatively high output levels (I design for 2V + sources) the high gain was not an issue.

SNR was sort of important (as you might gather from the performance of your unit) since I use high efficiency speakers with pretty extended LF response and everything else is also very quiet, so it was critical in my mind that it be quiet.

Tradeoffs were made, apparently I will need to figure out how to reduce the gain further for those who need less. (It's excessive for my needs too, I run mine on the -6dB gain tap.) I made no effort to invert one amplifier channel relative to the other because I don't need to do so. My plan was to recommend transformer coupling for those who need to invert or want balanced outputs. Logically a transformer with 2:1 or even 4:1 step down could be useful for those wanting less gain.

Now just a couple of quick observations..

I have done Dave's other suggested mods with blu tac (aka blue stik) and found that this resulted in further improvement.

I have also found with care that the OEM stylus may give very slightly better results provided you are playing clean records, and have done all of the other things previous discussed by Dave and I, otherwise it most definitely will not.

The Bliss is much less fussy, but still needs very careful set up to achieve its best.

I have done Dave's other suggested mods with blu tac (aka blue stik) and found that this resulted in further improvement.

I have also found with care that the OEM stylus may give very slightly better results provided you are playing clean records, and have done all of the other things previous discussed by Dave and I, otherwise it most definitely will not.

The Bliss is much less fussy, but still needs very careful set up to achieve its best.

Kevin,

I ordered R7 56Ω. But they sent me 1/4W not .5W. Are they ok to use? Thanks!

Are you sure they are 1/4W or just look like 1/4W? Modern metal films are considerably smaller than the venerable RN60 part.

- Home

- Source & Line

- Analogue Source

- Playing With Panasonic Strain Gauge Cartridges (And A Dedicated Phono Stage)