<snip> I think it may be safe bet to do it close to original length.

The few retips I have seen appear to match the same basic geometry and length as the original cantilever and stylus. They work.

Here’s an add I found on transmission speeds/specific gravity’s of various cantilever materials

JCarr designer of Lyra mc,s mentions this also . He did mention damping changes are needed other then a simple material swap.- Audiogon discussion-

This is beyond what most of us can accomplish or even the retippers.

Even though I will probably match them, you can see even when keeping the same lengths,

Bending strength modes are still different despite similiar dimensions. It is a violent vibrating system after all and everything matters

Regards

David

I would like to do it as well. I am wondering if this microscope is good enough.

AmScope M500C 40x-2500x Advanced Home School Compound Microscope 13964569094 | eBay

Adding a 5 mp camera, so I can measure the parameters.

Beware of the specs on useful magnification for inexpensive optics, eye relief goes hand in hand with this. I've been burned. Have you ever used a Nipkow disk microscope?

Last edited:

Here’s an add I found on transmission speeds/specific gravity’s of various cantilever materials

JCarr designer of Lyra mc,s mentions this also . He did mention damping changes are needed other then a simple material swap.- Audiogon discussion-

This is beyond what most of us can accomplish or even the retippers.

But they never fully admit WHY transmission speed matters. It's almost as if they've all worked out that cantilevers work as a transmission line,but none of them want to openly say that Shure got it wrong in their AES papers.

Beware of the specs on useful magnification for inexpensive optics, eye relief goes hand in hand with this. I've been burned. Have you ever used a Nipkow disk microscope?

No. I don't have any experience with microscope.

But they never fully admit WHY transmission speed matters. It's almost as if they've all worked out that cantilevers work as a transmission line,but none of them want to openly say that Shure got it wrong in their AES papers.

That's interesting since presumably they had the resources to figure all of this stuff out as one of the biggest cartridge makers on the planet. I'll admit I have wondered from time to time exactly how the cantilever plays its role, but haven't bothered to investigate - it requires physics I have forgotten or never knew.. (So many other things vying for more immediate attention) lol

View attachment 677142

Here’s an add I found on transmission speeds/specific gravity’s of various cantilever materials

JCarr designer of Lyra mc,s mentions this also . He did mention damping changes are needed other then a simple material swap.- Audiogon discussion-

This is beyond what most of us can accomplish or even the retippers.

Even though I will probably match them, you can see even when keeping the same lengths,

Bending strength modes are still different despite similiar dimensions. It is a violent vibrating system after all and everything matters

Regards

David

Very interesting. I had a Denon 103R re-tipped by Sound Smith with ruby cantilever/Optimized Contour Nude Contact Line Diamond. The sound was very "jumpy" if you know what I meant. But from the data you posted, the speed is lower than boron. It is not easy to get their ruby cantilever sound right. This may have something to do with the profile of tip too.

Here is a quotation from Audio-Technica's overview about their latest AT-ART1000 cartridge.

The AT-ART1000 (“ART” for Audio-Technica Reference Transducer) is Audio-Technica’s new flagship phono cartridge, handmade in Japan. Born of the pursuit of audio excellence that has driven A-T for more than 50 years, the AT-ART1000 introduces an innovative, audiophile design heretofore unseen in mass-produced cartridges. The cartridge’s direct power system places the dual moving coil directly on top of the stylus tip, ensuring that the audio quality does not suffer the negative effects normally introduced by the cantilever's length and material type.

This cartridge is very special. Its coils are directly mounted on the tip of cantilever. From their comments, it sounds like short cantilever is better.

The AT-ART1000 (“ART” for Audio-Technica Reference Transducer) is Audio-Technica’s new flagship phono cartridge, handmade in Japan. Born of the pursuit of audio excellence that has driven A-T for more than 50 years, the AT-ART1000 introduces an innovative, audiophile design heretofore unseen in mass-produced cartridges. The cartridge’s direct power system places the dual moving coil directly on top of the stylus tip, ensuring that the audio quality does not suffer the negative effects normally introduced by the cantilever's length and material type.

This cartridge is very special. Its coils are directly mounted on the tip of cantilever. From their comments, it sounds like short cantilever is better.

Others would and often do make the reverse argument, and those coils do have significant mass coupled directly to the stylus end of the beam. In conventional cartridge designs only a small % of the generator mass is reflected to the stylus. (lever and fulcrum)

I have not heard the ART cartridge, and many I respect say it is good, but there is no free lunch and it is just what particular trade offs you are willing to live with.

I have both a Windfeld and SPU A95 and I prefer these crummy little plastic bodied strain gauges to either. And I preferred those to anything else I've owned.

I have not heard the ART cartridge, and many I respect say it is good, but there is no free lunch and it is just what particular trade offs you are willing to live with.

I have both a Windfeld and SPU A95 and I prefer these crummy little plastic bodied strain gauges to either. And I preferred those to anything else I've owned.

The old JVC mc-1 had a similiar micro wafer coil attached near its tip like the AT design.

It doesn,t surprise me that a Denon 103 modded with a ruby cantilever sounded different, I understand from reading J Carr,s info , that Sound Smiths uses relatively heavy versions of the sapphire according to him.

I had 3 versions of the 103 with a SAEC tonearm back in the 80,s and never found satisfaction with them.

You here so much buzz with these because they were/are a cheap entry into the expensive MC world and thus all the chatter. Some like them regardless

With all the interesting white papers Shure produced, I never thought they sounded all that special. Given that research information, why didn’t they produced a light weight motor LOMC to add to their models line up ?

Some of those MM designs had really low peak resonances well inside the audible spectrum- moving mass again....

Regards

David

It doesn,t surprise me that a Denon 103 modded with a ruby cantilever sounded different, I understand from reading J Carr,s info , that Sound Smiths uses relatively heavy versions of the sapphire according to him.

I had 3 versions of the 103 with a SAEC tonearm back in the 80,s and never found satisfaction with them.

You here so much buzz with these because they were/are a cheap entry into the expensive MC world and thus all the chatter. Some like them regardless

With all the interesting white papers Shure produced, I never thought they sounded all that special. Given that research information, why didn’t they produced a light weight motor LOMC to add to their models line up ?

Some of those MM designs had really low peak resonances well inside the audible spectrum- moving mass again....

Regards

David

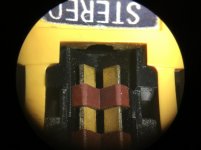

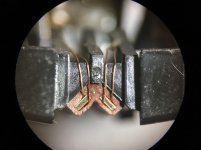

Take a look at the # 46 yellow body conical, I bet if you look closely you will notice another difference particularly relevant to the 450C and 451C cartridges. I hint that it has something to do with the coupler.

I have two of these replacements and they work/fit great on the 465C and are marginal on the 451C. Note that the 460/465C are quite different in some apparently (not) minor details from the earlier cartridges.

I have two of these replacements and they work/fit great on the 465C and are marginal on the 451C. Note that the 460/465C are quite different in some apparently (not) minor details from the earlier cartridges.

Hi AVWERK -

In your picture in post 550 there seems to be a ridge of epoxy a short distance in front of the coupler.

Is the rubber coupler still fixed to the cantilever or have you moved it? I am wondering if they can be moved or are they glued completely with what seems to be epoxy and maybe would tear if moving is attempted.

Dave

In your picture in post 550 there seems to be a ridge of epoxy a short distance in front of the coupler.

Is the rubber coupler still fixed to the cantilever or have you moved it? I am wondering if they can be moved or are they glued completely with what seems to be epoxy and maybe would tear if moving is attempted.

Dave

Yes it is stock. One could make a sharpened brass tubing the size of the cantilever and slowly rotate under the sponge rubber for removal

Messing with the compliance of different rubber or silicone will most likely change the frequency response ,just a guess on my part though.

Plus the SG elements are surrounded in a another soft material.

The whole shooting match is placed in a very soft environment overall when you start pressing in on the materials.

I will first make another removable cantilever aluminum structure to house the cantilever with set screws pressing in on a brass square post /cantilever Mount -with the screws on the sides so I can move the post left or right for needle centering and maybe up and down also.

This will require cutting out the body down to the mounting base where the removable tip structure stops. The aluminum will be captured with the mounting screws for rigidity.

I am beginning to think the actual body itself is maybe not a huge issue when you consider

The the amount of soft material the SG elements lay in. This may render a stiffer housing unnecessary. The voids should be filled in of course.

I will do the the cantilever structure first and then consider the body second, that way others could easily do the same if there is a sonic improvement

Tightening up and changing out all the soft materials to hard would be an interesting exercise and maybe an ultimate end game

Regards

David

Messing with the compliance of different rubber or silicone will most likely change the frequency response ,just a guess on my part though.

Plus the SG elements are surrounded in a another soft material.

The whole shooting match is placed in a very soft environment overall when you start pressing in on the materials.

I will first make another removable cantilever aluminum structure to house the cantilever with set screws pressing in on a brass square post /cantilever Mount -with the screws on the sides so I can move the post left or right for needle centering and maybe up and down also.

This will require cutting out the body down to the mounting base where the removable tip structure stops. The aluminum will be captured with the mounting screws for rigidity.

I am beginning to think the actual body itself is maybe not a huge issue when you consider

The the amount of soft material the SG elements lay in. This may render a stiffer housing unnecessary. The voids should be filled in of course.

I will do the the cantilever structure first and then consider the body second, that way others could easily do the same if there is a sonic improvement

Tightening up and changing out all the soft materials to hard would be an interesting exercise and maybe an ultimate end game

Regards

David

<snip>

Tightening up and changing out all the soft materials to hard would be an interesting exercise and maybe an ultimate end game

Regards

David

Hopefully you can do this is a way that is reversible if the consequence is a substantial change in frequency response. It's my belief, possibly mistaken that those materials are intended to control the frequency response of the transducers and possibly damp some unwanted resonances as well.

Maybe some sort of simplistic piezo actuator could be used to do crude frequency response measurements to establish a baseline response and then you can do a modification and remeasure to see what if any change occurred.

It would be interesting to see what if any of the original damping arrangements were retained in the UKW.

Hi-

"It would be interesting to see what if any of the original damping arrangements were retained in the UKW."

-reading through the patent is interesting. One thing I noticed is the frequency response plot (fig. 15) seems much better than the actual raw response plot measurements I have seen. The 7-20K peak is half of what I have seen.

There is a comment about the Sound Smith with + - 1dB from 50Hz to 12K response.

I wonder if that accuracy is possible with the technology versus what actually happened with production tolerances and assembly variation of the Panasonic line.

"It would be interesting to see what if any of the original damping arrangements were retained in the UKW."

-reading through the patent is interesting. One thing I noticed is the frequency response plot (fig. 15) seems much better than the actual raw response plot measurements I have seen. The 7-20K peak is half of what I have seen.

There is a comment about the Sound Smith with + - 1dB from 50Hz to 12K response.

I wonder if that accuracy is possible with the technology versus what actually happened with production tolerances and assembly variation of the Panasonic line.

- Home

- Source & Line

- Analogue Source

- Playing With Panasonic Strain Gauge Cartridges (And A Dedicated Phono Stage)