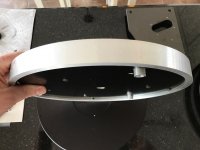

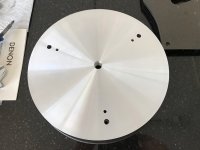

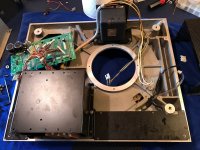

I didn't intend to work on this one for some time, but silicone oil leaked from the dampers during shipping; I had to tear it down to clean it off. It only made sense to go through it before putting it back together.

Attachments

Last edited:

Attachments

-

IMG_0336.jpg168 KB · Views: 631

IMG_0336.jpg168 KB · Views: 631 -

IMG_0335.jpg132.1 KB · Views: 632

IMG_0335.jpg132.1 KB · Views: 632 -

IMG_0333.jpg146.6 KB · Views: 638

IMG_0333.jpg146.6 KB · Views: 638 -

IMG_0332.jpg189.2 KB · Views: 641

IMG_0332.jpg189.2 KB · Views: 641 -

IMG_0329.jpg230.5 KB · Views: 647

IMG_0329.jpg230.5 KB · Views: 647 -

IMG_0342.jpg253.7 KB · Views: 657

IMG_0342.jpg253.7 KB · Views: 657 -

IMG_0321.jpg233.3 KB · Views: 656

IMG_0321.jpg233.3 KB · Views: 656 -

IMG_0320.jpg258 KB · Views: 670

IMG_0320.jpg258 KB · Views: 670 -

IMG_0319.jpg156.6 KB · Views: 657

IMG_0319.jpg156.6 KB · Views: 657 -

IMG_0318.jpg224.4 KB · Views: 673

IMG_0318.jpg224.4 KB · Views: 673

It’s rare to see any DD with a spring suspension.

Most DD,s have rigid chassis’s to keep it still while single mindedly focusing on speed stability and torque specs but lousy isolation as an end result

Nice to see Denon didn’t leave out that 3rd dimension to complete an important design to the real problem of acoustic feedback.

Nice find !

Most DD,s have rigid chassis’s to keep it still while single mindedly focusing on speed stability and torque specs but lousy isolation as an end result

Nice to see Denon didn’t leave out that 3rd dimension to complete an important design to the real problem of acoustic feedback.

Nice find !

I used the very unscientific method of seeing how fast different viscosities migrated down a piece of plastic at 45 deg as compared to the fluid that was in the dampers when I got the 'table. 300,000 CST seemed the most similar, and is what I used.

I also fashioned new covers for the damper bodies. In hindsight I should've added an o-ring as a wiper, which I may do later.

I also fashioned new covers for the damper bodies. In hindsight I should've added an o-ring as a wiper, which I may do later.

Attachments

Thank you! This is very interesting information. I think 300,000 is a lot. This is actually the viscosity of the toothpaste. I want to try 10000. This is used in cars in a visco muff. But, maybe you are right. It is necessary to try.

Still I am am disturbed with a question, it is necessary to open the engine in order to lubricate it, or not.

Still I am am disturbed with a question, it is necessary to open the engine in order to lubricate it, or not.

From what I can see, the spring suspension acts like a typical shock and that means stiction

created by the o ring or wiper?

If it were mine, I would eliminate it and cover the spring mechanism with an aluminum tube

Sealed at the base and fill the whole tube/spring up with fluid.

It would look better and still damp it without the micro locking of an o ring/wiper interface IF it actually touches the shaft.

Regards

David

created by the o ring or wiper?

If it were mine, I would eliminate it and cover the spring mechanism with an aluminum tube

Sealed at the base and fill the whole tube/spring up with fluid.

It would look better and still damp it without the micro locking of an o ring/wiper interface IF it actually touches the shaft.

Regards

David

I didn't intend to work on this one for some time, but silicone oil leaked from the dampers during shipping; I had to tear it down to clean it off. It only made sense to go through it before putting it back together.

HI,

Very nice TT and nice project as well. Congratulation, not easy to find these TT, even harder in good conditions. Which TA shall you use and which cart?

Rgds

Adelmo

Hi All, just acquired a DP-100, got some questions in restoring the unit with speed adjustments, power buttons and most importantly the shock. Anyone has any idea where I can find the related information?

Thanks all!

I'm not sure exactly what you need...? I wasn't able to find a schematic for it, so I riffed off the DN-308 schematic, but that was many years ago.

HI,

Very nice TT and nice project as well. Congratulation, not easy to find these TT, even harder in good conditions. Which TA shall you use and which cart?

Rgds

Adelmo

I bought a 3012 for it as that's the armboard that came with it, though I've no love for SME arms. Years ago I saw a DA-1000 with the OEM armboard for sale, but the asking price was beyond my sensibilities, and I sometimes regret not grabbing it.

During transportation, some of the fluids came out, so I will need to do a full disassembly to clean those gunk off. I will then need to refill the fluid and a replacement cover for those shock will also be great, would love to know what you have used to make those covers and also replacement fluid. Lastly the on/off button on my unit does not stick, so I will need to find out the reason why and replace the needed part.I'm not sure exactly what you need...? I wasn't able to find a schematic for it, so I riffed off the DN-308 schematic, but that was many years ago.

Thank you so much for your help =]

I saw you make new covers for the dampers, how do you make them and what materials you made them out of? What sort of damping fluid you have used and where did you buy them? Sorry for so many questions.

The power button is a soft button. But the soft function does not work anymore. So I have to press it continuously in order to make the machine stay on.

The power button is a soft button. But the soft function does not work anymore. So I have to press it continuously in order to make the machine stay on.

What sort of silicone fluid you use at last?The final version of the silicone fluid for shock absorbers: 17 ml and a viscosity of 60,000 cst.

The result is very good.

I saw you make new covers for the dampers, how do you make them and what materials you made them out of? What sort of damping fluid you have used and where did you buy them? Sorry for so many questions.

The power button is a soft button. But the soft function does not work anymore. So I have to press it continuously in order to make the machine stay on.

Rubber sheet, hole punches, and contact adhesive. Damping fluid is just silicone oil. For small quantities it used to be easiest to find it at hobby shops as it's used in RC differentials. I still have plenty left from ears ago so I haven't bought any since.

For the power latching circuit you'd need to figure out the circuit so it can be troubleshot. I don't have a schematic for that.

- Home

- Source & Line

- Analogue Source

- Denon DP-100