Hi all, having read several threads about linear trackers and seen the DIY efforts of many dedicated members here of the glass tube variety, ala clearaudio etc got me thinking. I don't like the ball bearing inside or outside a glass or metal tube/round bar idea as it seems to me unlikely a ball bearing will rotate without sufficient weight as the friction within the bearing will prevent this and it may slide first. Now I don't want this to dominate this thread and it's only my thoughts and may have no foundation. It's just made me think would it be possible to have a tube with the slot at the top with the carriage floating inside on some form of liquid, either water or thin oil etc. Like a well tempered arm but linear. Has it been done?

the most popular method has been using compressed air but yes fluids have been used. The trouble with all of these designs is that they miss the benefit that mechanical systems provide which is damping of arm assembly motion to prevent resonance. If you watch any of the numerous you tube videos of mechanical bearing assemblies you will find that when set up properly they roll very effectively. Remember that the bearings are run dry of lubricants which are not necessary or desirable at the speed of rotation involved and they only create drag. The fact that the arm and carriage have to be dragged up the inside wall of the glass tube as in the Opus3 Cantus is a plus not a negative as the arm has enough damped motion to accommodate normal record surface variations but should a bad warp come along you can still track the warp and not have you arm go into uncontrolled resonance. The less easily your are can move away from where it needs to be the better for energy transfer. That why Bo's design is so very clever, it moves freely right to left and is damped during any up and down motion especially so with severe warps. gravity is enlisted to pull the carriage assembly back down to its correct position after a warp has passed. This aspect of Bo's design is missed by many who simply do not understand what is happening. Yes you can play much more severely warped records when the arm is allowed free swing up and down but that simply degrades performance and severely warped records will never sound good even it you can track them. remember that Bo and Opus 3 were the first to impost and sell the Souther linear tracking arm into Europe. Bo saw this short coming in Lou's design and asked Lou to address it. Lou felt the arm was fine as it was and suggest that Bo design his own and see if it was an improvement. Not long after the Cantus was born and Bo stopped selling the Souther arm.

the only way that you will know for sure is to build both designs and compare. I suppose that you could compare Bo's design to an air bearing to see how they differ. trouble with a free floating carriage in a liquid trough will be unrestricted motion of the carriage in all sorts of directions and you have no way to damp them even when using a keel of some sort a viscous fluid will be required and then you add a huge amount of friction. Why don't you give it a try and see what you discover?

the only way that you will know for sure is to build both designs and compare. I suppose that you could compare Bo's design to an air bearing to see how they differ. trouble with a free floating carriage in a liquid trough will be unrestricted motion of the carriage in all sorts of directions and you have no way to damp them even when using a keel of some sort a viscous fluid will be required and then you add a huge amount of friction. Why don't you give it a try and see what you discover?

Done, by Mr. Grimm. Very good job, methinks.

The solid universe: Vinyl audio: DIY linear tonearm

and his video:

https://www.youtube.com/watch?v=q4hKgkyPVt8&feature=youtu.be

Very interesting.

The solid universe: Vinyl audio: DIY linear tonearm

and his video:

https://www.youtube.com/watch?v=q4hKgkyPVt8&feature=youtu.be

Very interesting.

Mmm yes, I've seen that before, but while watching the video there was another more interesting arm Orpheus designer, or desinger as it was spelt. On an sp10, now that I would like to know more about. Couldn't anything searching online. I must sign or register on you tube to contact the person responsible for the video.

link to the tonearm on youtube

https://www.youtube.com/watch?v=-WPDKXlQL9I

seems its an air bearing but can only guess as to how its done

https://www.youtube.com/watch?v=-WPDKXlQL9I

seems its an air bearing but can only guess as to how its done

link to the tonearm on youtube

https://www.youtube.com/watch?v=-WPDKXlQL9I

seems its an air bearing but can only guess as to how its done

the captive air bearing is to the right in the metal block and the tube which the tonearm is attached to slides in the air bearing.

I guessed that much. looks like a difficult engineering job. I assume the air holes are all around the shaft to stop it from being pushed up and scraping on the top of the housing. I am thinking instead of an air bearing, linear bearings and a hollow shaft, I will go to my local bearing supplies and talk to them, the bearings would need to be unsealed and dry. I was thinking to build one with linear bearings before but with the carriage fixed to the linear bearing but this way looks more user friendly if it works well enough and retracts away from the record without the need to move the whole carriage.the captive air bearing is to the right in the metal block and the tube which the tonearm is attached to slides in the air bearing.

I guessed that much. looks like a difficult engineering job. I assume the air holes are all around the shaft to stop it from being pushed up and scraping on the top of the housing. I am thinking instead of an air bearing, linear bearings and a hollow shaft, I will go to my local bearing supplies and talk to them, the bearings would need to be unsealed and dry. I was thinking to build one with linear bearings before but with the carriage fixed to the linear bearing but this way looks more user friendly if it works well enough and retracts away from the record without the need to move the whole carriage.

This seems like a 13 mm New Way air bearing. It is about $200 each in the States. However, the design in the video is not well implemented.

Last edited:

could you elaborate on that please.This seems like a 13 mm New Way air bearing. It is about $200 each in the States. However, the design in the video is not well implemented.

could you elaborate on that please.

The arm in the video uses only one air bearing. It is not enough. The length of air bearing is 2 inch. 2 inch length may not be long enough to hold the shaft straight from most outer groove to most inner groove. I was told by manufactory that the pressure is evenly distributed inside of air bearing. But I always suspect that the pressure in middle of air bearing is higher than that at both ends of air bearing. Therefore, it makes things even worse.

The counter weight should be on the opposite side of shaft. However, this could be design dependent. To my experience, it is not desirable.

A damping mechanism is a must for all air bearing arms. There is no damping mechanism on this arm.

After experiencing the many benefits of a mechanical linear system I cannot imaging using an air bearing. The assumed benefits of the ultra low friction are a smoke screen. Air bearings mean that your arm has the ability to resonate freely in both the horizontal plane as well as in the vertical plane and you have no way to stop it. Air bearing are one of those make just one aspect of the design perfect and everything else will be perfect too approaches to design and it is simply not the case. Very flawed thinking.

The main benefit of an air bearing arm is NOT frictionless, but it is controllable friction ( damping). Due to almost frictionless of an air bearing, you can control the damping to fit the compliance of a cartridge, moving mass and force interaction. For air bearing arm, frictionless is not a complete story.

For a mechanical linear arm, for example, ball bearing arm, it starts with certain level of friction. In other words, it sets a base level of damping already. You have to design all other elements, such as mass, weight distribution and force interactions to fit the base level of damping caused by ball bearing. It is a black box. The only way to get it right is trial and error. Even you finally get the optimal carriage design, it may still change. For example, the VTF changes on the Cantus arm. The difference of VTF can be as much as 2 grams. You loose control again. Bearing shatter is another problem. It causes irregularity of damping. Not to mention that all ball bearing designs can’t hold stiff pivot point while ball bearings travel. Air bearing can hold the pivot point so stiff but frictionless while it travels. Is there any medium better than that? I don’t think so. A silicone though can provide a consist and controllable damping force for air bearing.

Air bearing is the best medium, but it comes with a burden, i.e. noisy air compressor which keeps a lot of people away from air bearing arm.

For a mechanical linear arm, for example, ball bearing arm, it starts with certain level of friction. In other words, it sets a base level of damping already. You have to design all other elements, such as mass, weight distribution and force interactions to fit the base level of damping caused by ball bearing. It is a black box. The only way to get it right is trial and error. Even you finally get the optimal carriage design, it may still change. For example, the VTF changes on the Cantus arm. The difference of VTF can be as much as 2 grams. You loose control again. Bearing shatter is another problem. It causes irregularity of damping. Not to mention that all ball bearing designs can’t hold stiff pivot point while ball bearings travel. Air bearing can hold the pivot point so stiff but frictionless while it travels. Is there any medium better than that? I don’t think so. A silicone though can provide a consist and controllable damping force for air bearing.

Air bearing is the best medium, but it comes with a burden, i.e. noisy air compressor which keeps a lot of people away from air bearing arm.

Having not seen the new way air bearing bushings I assumed there were two bearings,one at each end but can now see there is only the one in blue. Do you mean the counterweight should be the other end of the shaft not the other side. That could also serve as the arm lift then.

I wouldn't find the compressor a problem as my dedicated listening room is in the garden very close to a garden shed where I could put the compressor.

I wouldn't find the compressor a problem as my dedicated listening room is in the garden very close to a garden shed where I could put the compressor.

Last edited:

Super you should post a picture of your arm here, I think some people would find it really interesting.

As a user of a Souther arm with ball bearings his comments on the problems of ball bearing based linear trackers is valid. I like mine, but it is not headache free and I suspect air bearing arms may in some respects work better.

As a user of a Souther arm with ball bearings his comments on the problems of ball bearing based linear trackers is valid. I like mine, but it is not headache free and I suspect air bearing arms may in some respects work better.

i checked out the site but cannot find a 13mm hollow shaft as yet.

super10018: Bo do a good number of comparative demonstrations between his Opus3 master tape recordins played back on the machine he had personally built to record them on with the Opus 3 vinyl records played on his Continuo turntable fitted with his C

Cantus tone arm. These demonstrations were all done blind to the listeners who never knew what source that they were listening to. The up shot was golden ears listeners could not do better than guess if they were hearing the master tape or the vinyl record. I think that Bo achieved a very high level of success with his arm design. Bo never saw the need to try to improve it further as he felt that to make it any better served no real purpose.

We can agree to disagree on air bearing arm designs.

Cantus tone arm. These demonstrations were all done blind to the listeners who never knew what source that they were listening to. The up shot was golden ears listeners could not do better than guess if they were hearing the master tape or the vinyl record. I think that Bo achieved a very high level of success with his arm design. Bo never saw the need to try to improve it further as he felt that to make it any better served no real purpose.

We can agree to disagree on air bearing arm designs.

They don’t have hollow shaft. I use two 1/2” air bushings and bought a 12” long 1/2” aluminum shaft from

McMaster-Carr

I found a local machine shop to drill a 1/4” hole all way through along the shaft. The tolerance of aluminum shaft is not ideal but it works.

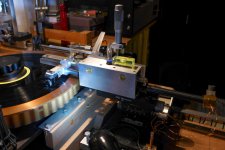

In fact, I built two air bearing arms. One is moving bearing(i.e. the shaft is stationary). The other one is moving shaft(i. e. bearing is stationary). I keep updating the arms. It has been two years since I built first version of air bearing arm.

If you want to build a air bearing arm, the first thing you need to think about is air compressor. Noise is the main issue. You can’t put the compressor in the same room you listen. I put mine in the closet. Also, if you want to build a moving shaft kind of arm. The compressor has to be at least 1/2 hp such as Silentaire, Super Silent 50-TC to have enough flow to supply to two bearings. This is the one I am using now.

McMaster-Carr

I found a local machine shop to drill a 1/4” hole all way through along the shaft. The tolerance of aluminum shaft is not ideal but it works.

In fact, I built two air bearing arms. One is moving bearing(i.e. the shaft is stationary). The other one is moving shaft(i. e. bearing is stationary). I keep updating the arms. It has been two years since I built first version of air bearing arm.

If you want to build a air bearing arm, the first thing you need to think about is air compressor. Noise is the main issue. You can’t put the compressor in the same room you listen. I put mine in the closet. Also, if you want to build a moving shaft kind of arm. The compressor has to be at least 1/2 hp such as Silentaire, Super Silent 50-TC to have enough flow to supply to two bearings. This is the one I am using now.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Linear tracking arm in liquid