super10018: Bo do a good number of comparative demonstrations between his Opus3 master tape recordins played back on the machine he had personally built to record them on with the Opus 3 vinyl records played on his Continuo turntable fitted with his C

Cantus tone arm. These demonstrations were all done blind to the listeners who never knew what source that they were listening to. The up shot was golden ears listeners could not do better than guess if they were hearing the master tape or the vinyl record. I think that Bo achieved a very high level of success with his arm design. Bo never saw the need to try to improve it further as he felt that to make it any better served no real purpose.

We can agree to disagree on air bearing arm designs.

Well, actually I would really like to learn that what are the shortcomings of an air bearing arm except the trouble of air compressor and cost of air bearings.

having seen the technics SP10 with the " poorly implemented " linear arm its got my attention. Obviously it would need a sliding rotating bush at each end of the travel as I would have expected from the SP10 version and maybe it does have something at the back end. The air bearing probably works well but I really don't want the faff of a compressor. So I was talking to a bearing supplier about sliding rotating bushes and the ball bearing type are very expensive and the smallest is 12mm ID, a hollow shaft to suit would weigh about 240grams, that sounds too heavy to me but maybe someone could enlighten me. 8mm ptfe bushes that the chap assures me would work with a polished shaft are reasonably priced but an 8mm shaft is only available solid and so weighs the same as the 12mm hollow shaft. Then again it probably weighs a little less as the wall thickness of the 12mm hollow shaft is 4mm but a bigger circumference. Whatever the cost of the 8mm shaft and two ptfe bushes is only £50 and so may be worth a punt. Any thoughts welcome,

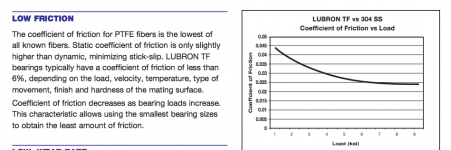

As I said the bearing man said the Ptfe bushes and a polished shaft has virtually no friction. I have decided the shaft moving is going to be too heavy which is a shame as it's such a simple uncomplicated idea and to do it right needs the air bearing bushes which are expensive. So I will try the Ptfe bush sliding on a polished round bar.

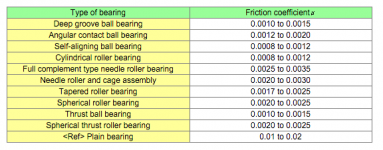

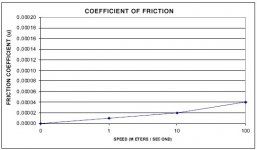

Virtually no friction? I don't think so. Here are the coefficient of friction for ptfe bushing, ball bearings and air bearing. You can see the difference yourself. The coefficient of friction for ball bearings are lower than ptfe bushing. Look the air bearing. Its coefficient of friction is .00004 at 100 meter per second. Any thing better than that? No. How fast does a tone arm moves? a millimeter per second? So, its coefficient of friction is way less than .00002, almost 0.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.