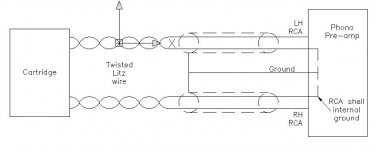

Despite searching (not just this forum but also the web!) I cannot find a diagram showing complete wiring from cartridge to phono pre-amp.

I have used twisted litz wire from cartridge to plinth.

I have used (because I had some) balanced (2 cores plus screen) cable (1 cable per channel) from plinth to RCA plug at phono pre-amp, using the 2 cores.

The screen is only connected to ground wire at the plinth and the ground wire is fixed to ground terminal at phono pre-amp (Project phonobox).

I have audible hum at normal listening levels.

I guess using balanced cable is probably the problem?

Please see attached diagram and advise where I have gone wrong.

A diagram would make a good "sticky"

I have used twisted litz wire from cartridge to plinth.

I have used (because I had some) balanced (2 cores plus screen) cable (1 cable per channel) from plinth to RCA plug at phono pre-amp, using the 2 cores.

The screen is only connected to ground wire at the plinth and the ground wire is fixed to ground terminal at phono pre-amp (Project phonobox).

I have audible hum at normal listening levels.

I guess using balanced cable is probably the problem?

Please see attached diagram and advise where I have gone wrong.

A diagram would make a good "sticky"

Attachments

This actually sounds quite right to me.

The two signal wires of each coil should not be connected anywhere to the shield or case or ground, only to the preamp's input. Using balanced cables makes this easy. The shield of that balanced cable should be connected directly to the case of the preamp (via a dedicated screw terminal usually), not to the signal ground! The signal ground will be connected to the case inside the preamp, but that should be the only connection.

The tone arm should be connected to the shield, too (but again not to the signal ground), as long as it is made out of metal and the tonearm wires actually run through it .

.

Your graph looks like you connected the cable shield to the plinth only and run a ground wire from there to the preamp. I'd connect the cable shield at the preamp's end to the preamp and at the other end to the plinth and tone arm ground cable. You will make sure that the signal wires from the cartridge to the preamp are contained in a shield "tunnel" for as long as possible...

The two signal wires of each coil should not be connected anywhere to the shield or case or ground, only to the preamp's input. Using balanced cables makes this easy. The shield of that balanced cable should be connected directly to the case of the preamp (via a dedicated screw terminal usually), not to the signal ground! The signal ground will be connected to the case inside the preamp, but that should be the only connection.

The tone arm should be connected to the shield, too (but again not to the signal ground), as long as it is made out of metal and the tonearm wires actually run through it

Your graph looks like you connected the cable shield to the plinth only and run a ground wire from there to the preamp. I'd connect the cable shield at the preamp's end to the preamp and at the other end to the plinth and tone arm ground cable. You will make sure that the signal wires from the cartridge to the preamp are contained in a shield "tunnel" for as long as possible...

Hey guys, thanks for the input.

Arm is a DIY WTL so not ideal for carrying out experiments - you wouldn't want to spill the silicon!

However, I have mocked up a copy of the wiring using a spare cartridge.

Grounding sheath at phono end made some improvement - phono input has v short link wire straight to ground screw so makes no difference whether sheath connects to RCA shell or earth screw. Made no difference whether I used blue core for signal return or sheath for signal return. Swapping a cover screw for a screw with serrated head ensured the phono box cover wasn't a source of hum (it was before I swapped the screw!). Still got hum above 50% amplifier volume position. No hum on other input sources. Tone arm tube is Carbon Fibre (for its amazing looks) and I have checked with test meter - it is conductive so I can feel an earth connection coming and more experiments.

Arm is a DIY WTL so not ideal for carrying out experiments - you wouldn't want to spill the silicon!

However, I have mocked up a copy of the wiring using a spare cartridge.

Grounding sheath at phono end made some improvement - phono input has v short link wire straight to ground screw so makes no difference whether sheath connects to RCA shell or earth screw. Made no difference whether I used blue core for signal return or sheath for signal return. Swapping a cover screw for a screw with serrated head ensured the phono box cover wasn't a source of hum (it was before I swapped the screw!). Still got hum above 50% amplifier volume position. No hum on other input sources. Tone arm tube is Carbon Fibre (for its amazing looks) and I have checked with test meter - it is conductive so I can feel an earth connection coming and more experiments.

another thing that makes a difference is the type of motor used on the TT, AC motors create a bad AC field that can sometimes be audible and usually only when using a MM cartridge. if the hum is louder the closer it gets to the motor then you have found your problem.

you dont need to 'ground' your plinth unless its made of metal and even so only to the household PE. you do however you need to 'ground' your arm depending on arm wand/headshell material.

wiring goes like:

Red = Right + (hot)

Green = Right - (cold)

White = Left + (hot)

Blue = Left - (cold)

Black would = 'ground' which would run from your arm wand to the ground tab on your phonostage case.

some cartridges have an internal screen and this can bee seen as on the back of the cartridge as a tab usually connected to the Right - (cold), if there is then try and get your cartridge pin connector to touch the tab. if your arm wand is made of wood but the headshell is made of metal then you can cheat and use a Y from the Right - to the headshell but only if the cartridge has an internal shield as mentioned.

you dont need to 'ground' your plinth unless its made of metal and even so only to the household PE. you do however you need to 'ground' your arm depending on arm wand/headshell material.

wiring goes like:

Red = Right + (hot)

Green = Right - (cold)

White = Left + (hot)

Blue = Left - (cold)

Black would = 'ground' which would run from your arm wand to the ground tab on your phonostage case.

some cartridges have an internal screen and this can bee seen as on the back of the cartridge as a tab usually connected to the Right - (cold), if there is then try and get your cartridge pin connector to touch the tab. if your arm wand is made of wood but the headshell is made of metal then you can cheat and use a Y from the Right - to the headshell but only if the cartridge has an internal shield as mentioned.

I recently finished a Rega arm rebuild.

One of the things I did was to earth the arm, by tapping a 3mm bolt into the armshell at the top with a separate earth wire from this bolt back to the grounding point. It made an enormous difference in terms of reducing noise - especially as Rega's use an AC motor.

One of the things I did was to earth the arm, by tapping a 3mm bolt into the armshell at the top with a separate earth wire from this bolt back to the grounding point. It made an enormous difference in terms of reducing noise - especially as Rega's use an AC motor.

Have earthed carbon fibre wand - tried M3 screw first but thread stripped so used a PC 6-32 to M3 brass standoff - the 6-32 course thread tapped itself into the wand.

I have an ex-printer stepper motor, d-spin microstepping driver and Arduino. Motor power is 32v DC ex printer wallwart, Arduino power is 5v DC wallwart charger. Both supplies are 2 wire, no earth. Hum when either supply was plugged into mains. Grounding the metal box housing the Arduino & driver caused a wonderful silence. The box is far side of plinth away from cartridge. Plinth is wood. Who'd 've thought?

I was intending to tidy up this side of things when project was fully functional but didn't expect it to be a source of hum and still don't understand why it should be.

I have an ex-printer stepper motor, d-spin microstepping driver and Arduino. Motor power is 32v DC ex printer wallwart, Arduino power is 5v DC wallwart charger. Both supplies are 2 wire, no earth. Hum when either supply was plugged into mains. Grounding the metal box housing the Arduino & driver caused a wonderful silence. The box is far side of plinth away from cartridge. Plinth is wood. Who'd 've thought?

I was intending to tidy up this side of things when project was fully functional but didn't expect it to be a source of hum and still don't understand why it should be.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Tonearm wiring