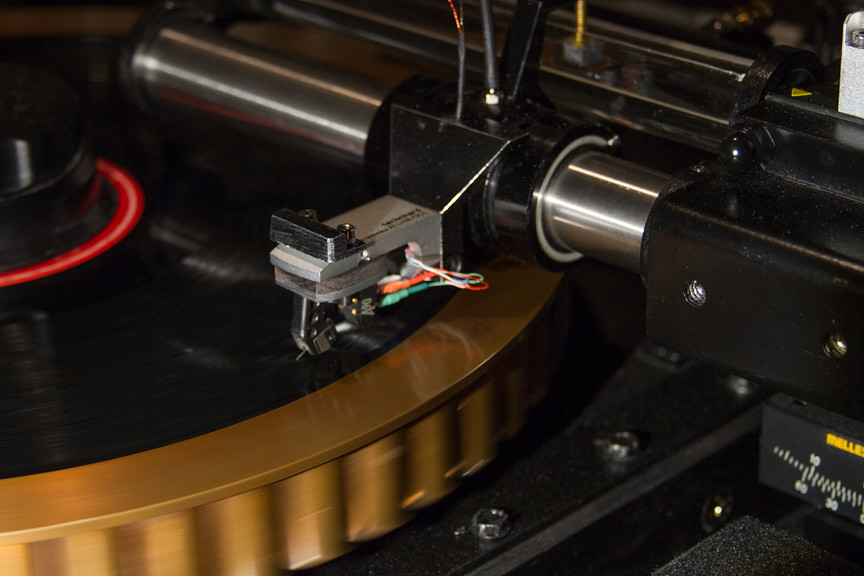

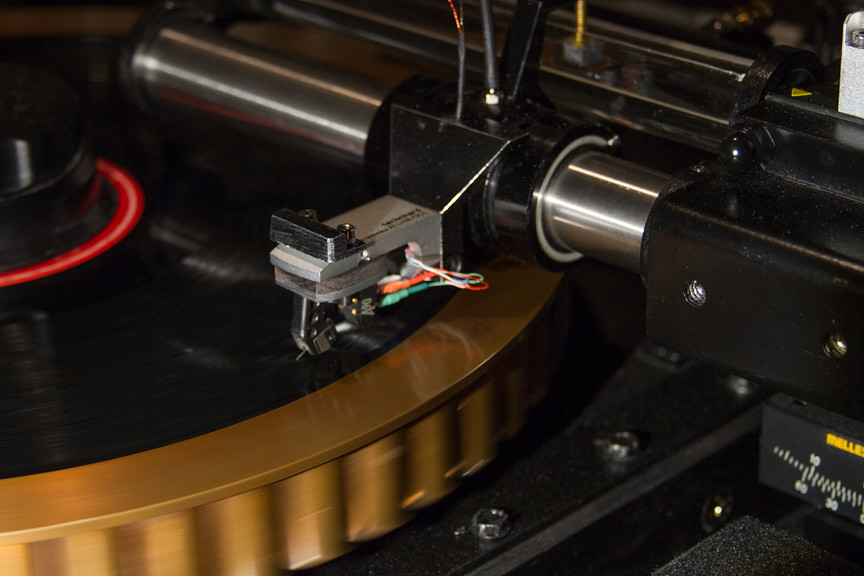

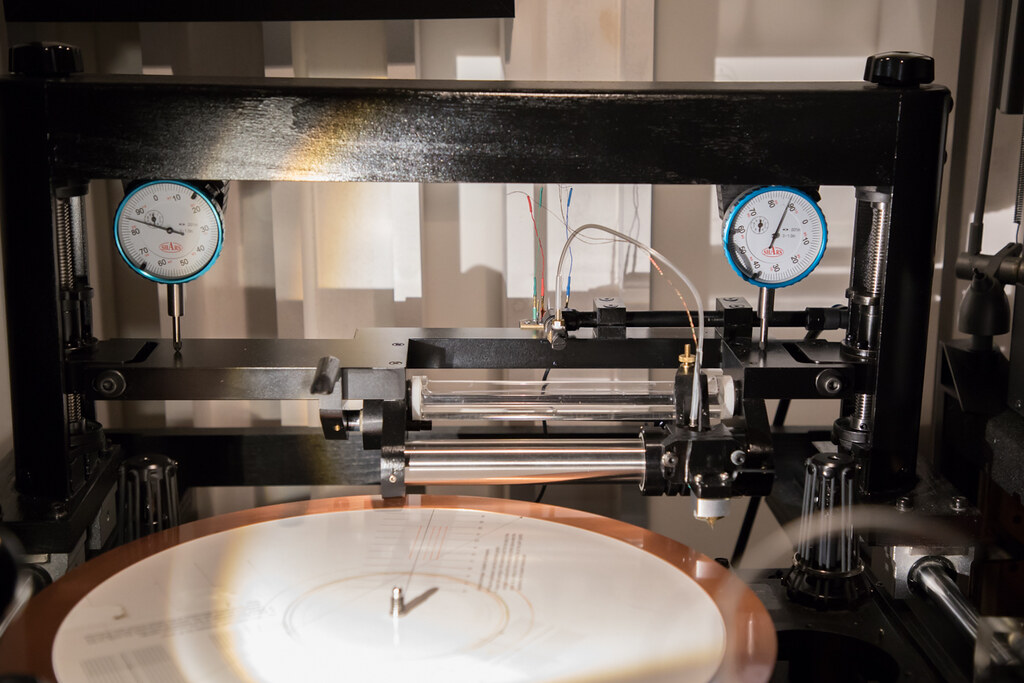

I made another version of my diy air bearing arm.

The goals for this version of arm was to reduce the total mass in order to work better with medium compliance cartridge and to further simplify the arm structure.

The old version of arm was about 200 grams. The new version is about 135 gram now. I also designed the arm which can use after market head shells. The one I am using now is Audio-technica AT-LH18 Techni hard head shell. I am thinking to try Yamamoto HS-6 All Titanium Head shell later on.

The material for this version of arm is 7075 aluminum alloy.

I also re-did the counter weight part.

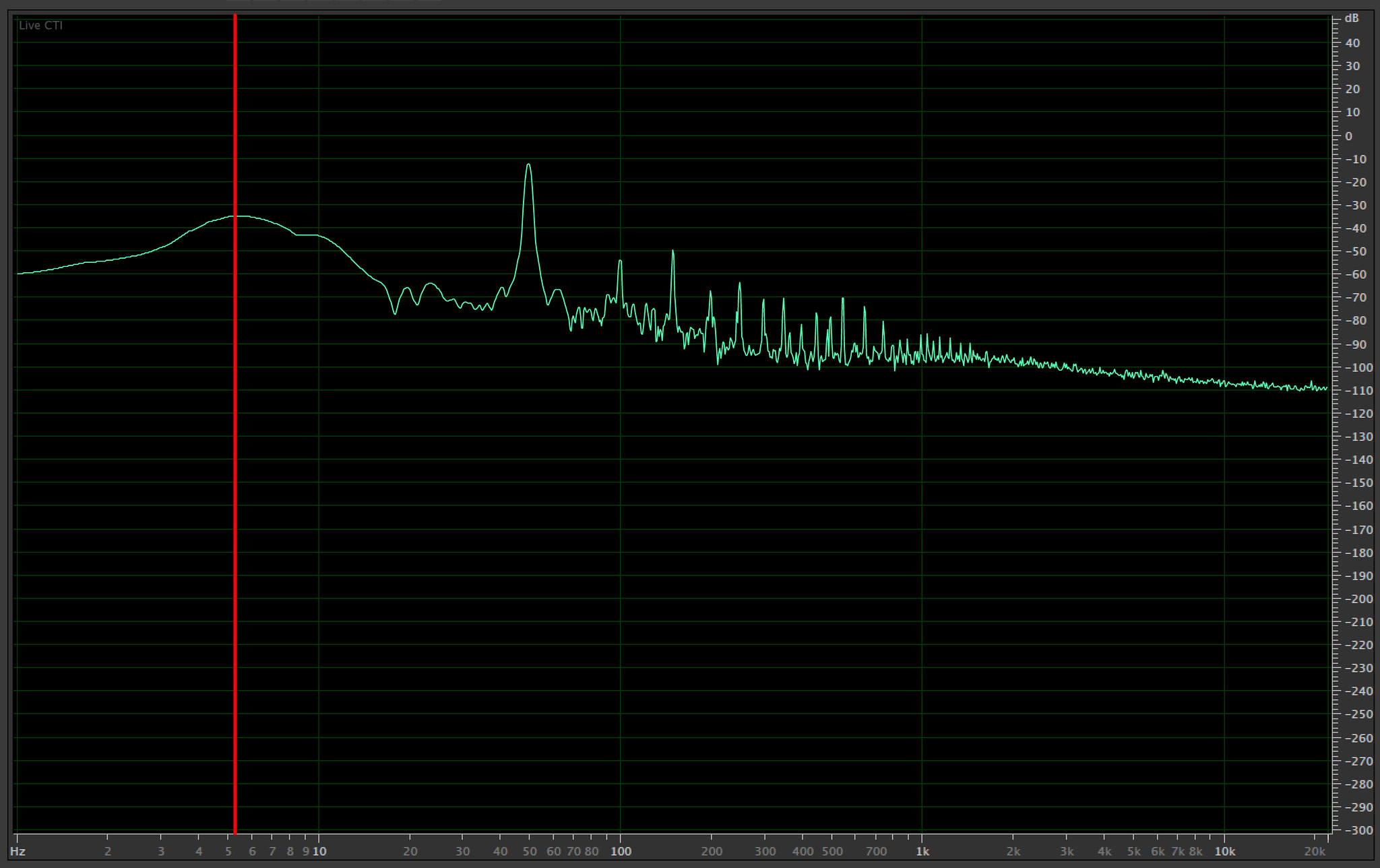

The arm/cartridge resonance for the new arm is about 5 Hz vertically and horizontally.

After many days fine turning, I have never heard Ortofon A90 can sing so good as it does now.

The goals for this version of arm was to reduce the total mass in order to work better with medium compliance cartridge and to further simplify the arm structure.

The old version of arm was about 200 grams. The new version is about 135 gram now. I also designed the arm which can use after market head shells. The one I am using now is Audio-technica AT-LH18 Techni hard head shell. I am thinking to try Yamamoto HS-6 All Titanium Head shell later on.

The material for this version of arm is 7075 aluminum alloy.

I also re-did the counter weight part.

The arm/cartridge resonance for the new arm is about 5 Hz vertically and horizontally.

After many days fine turning, I have never heard Ortofon A90 can sing so good as it does now.

Last edited:

I have done two air bearing arms so far although I did serval versions for each arms. The first arm is a pure pleasure to use it. Every adjustments can be very easily and accurately made. It sounds great, too. This arm has total mass about 130 grams. It excels with medium and low compliance cartridges.

However, I couldn’t say the same for another arm. The other arm did sound great, too. It had total mass about 200 grams. It worked very well with low compliance cartridges. It had no damping device and was not easy to make adjustments. So, I decided to modify this arm again.

First, I reduced the arm’s total mass. It is about 170 grams now. I keep this arm in relatively heavy mass because I plan to have three arms with different total masses to work with different cartridges. My plan is to have three arms with 80, 130 and 170 grams respectively. So, I can have wide choice to match different cartridges. Heavy arm usually has better bass.

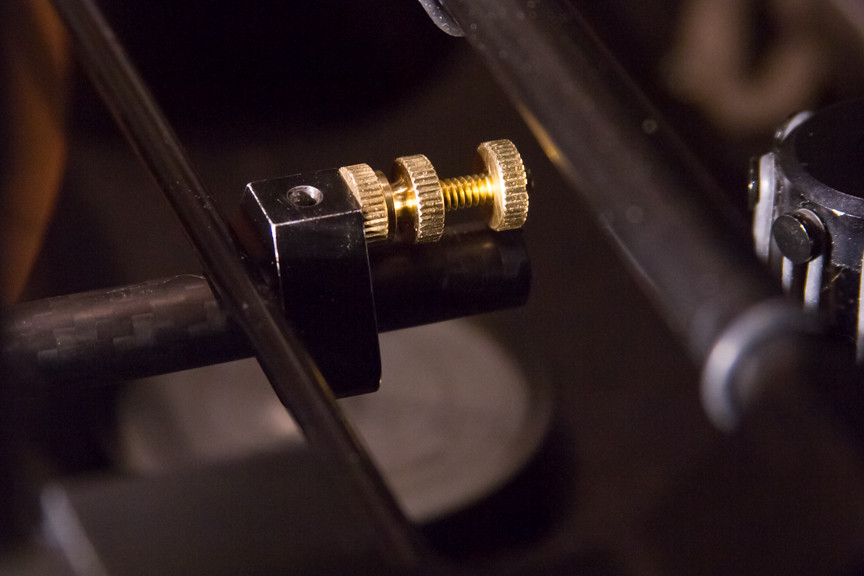

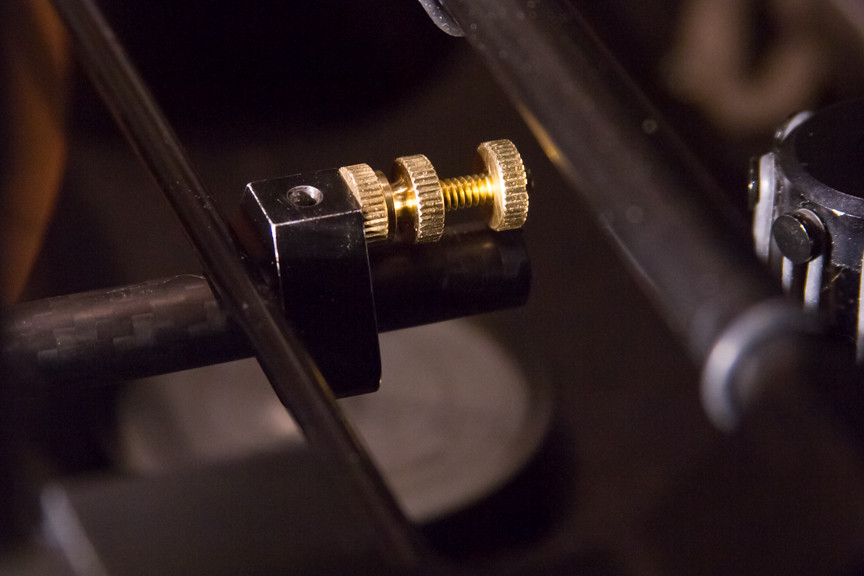

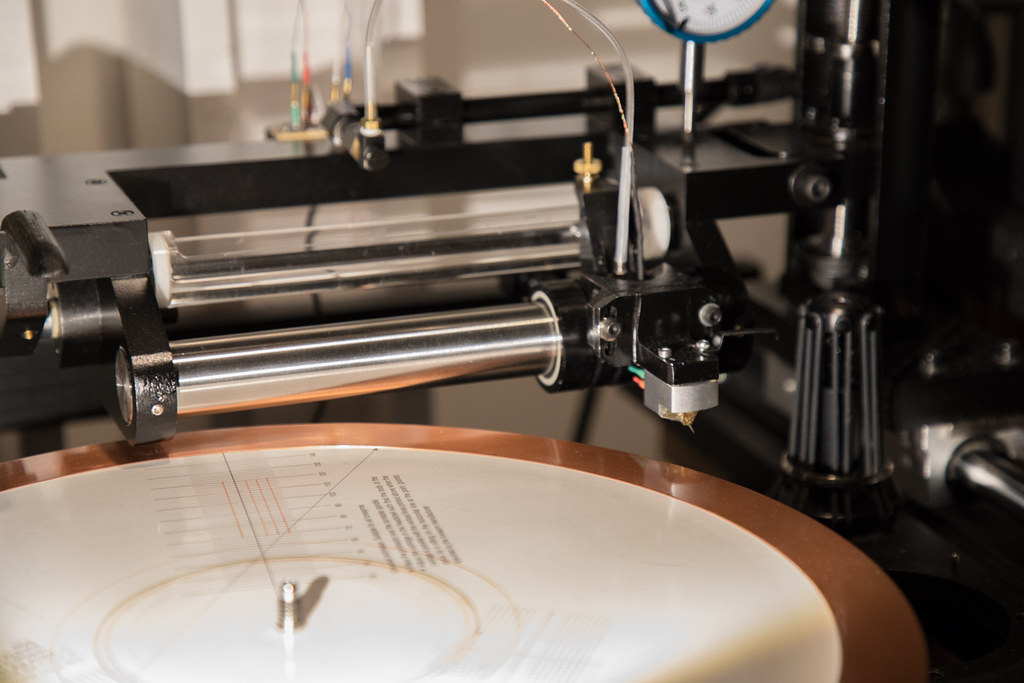

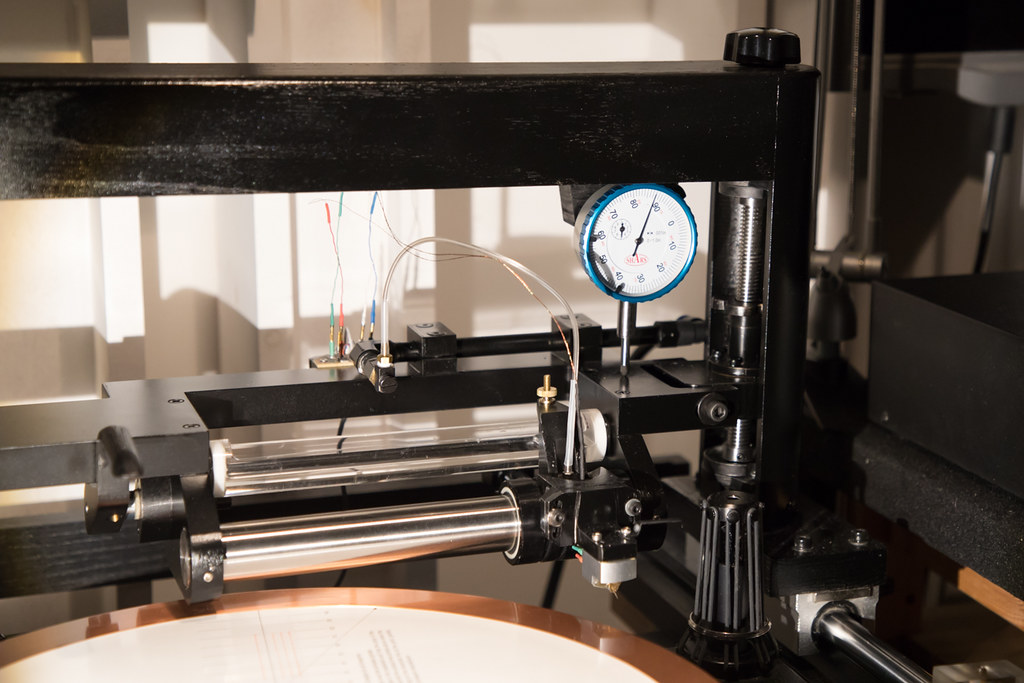

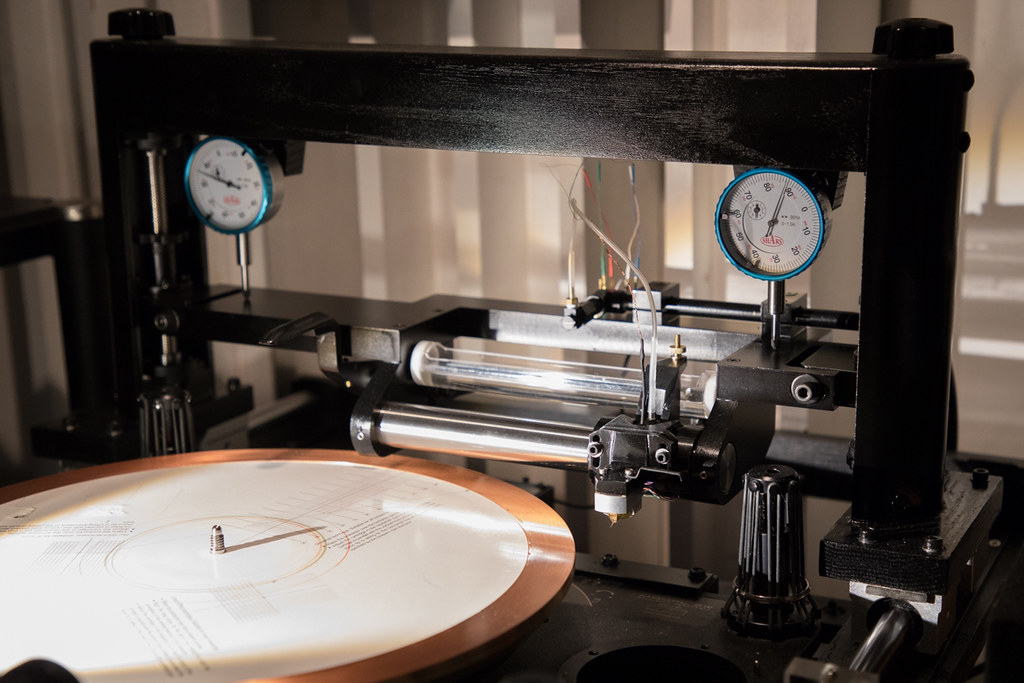

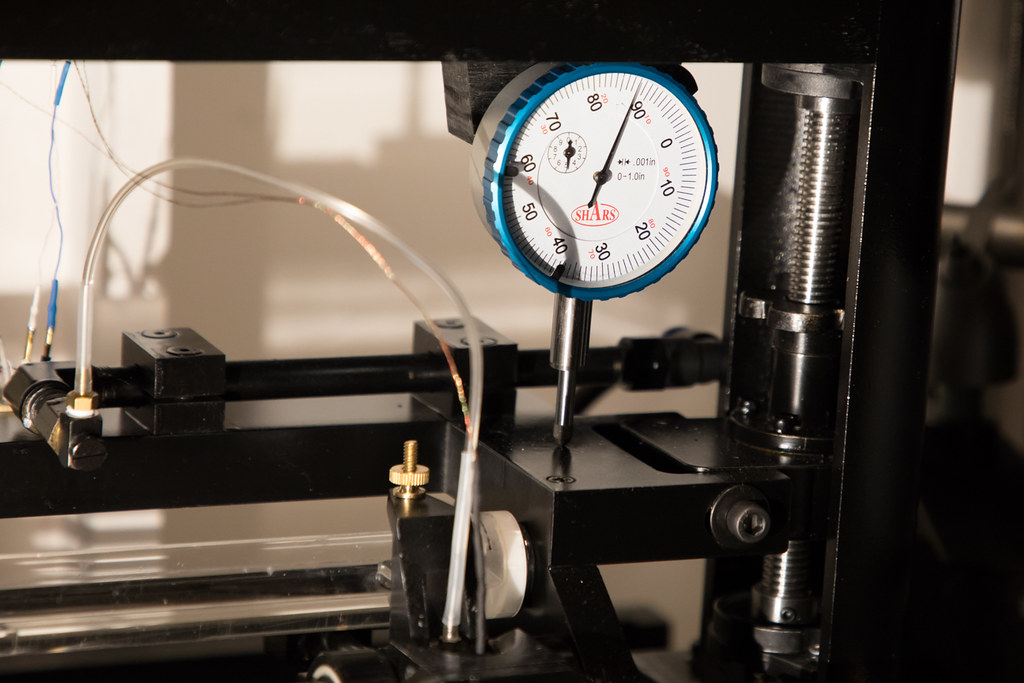

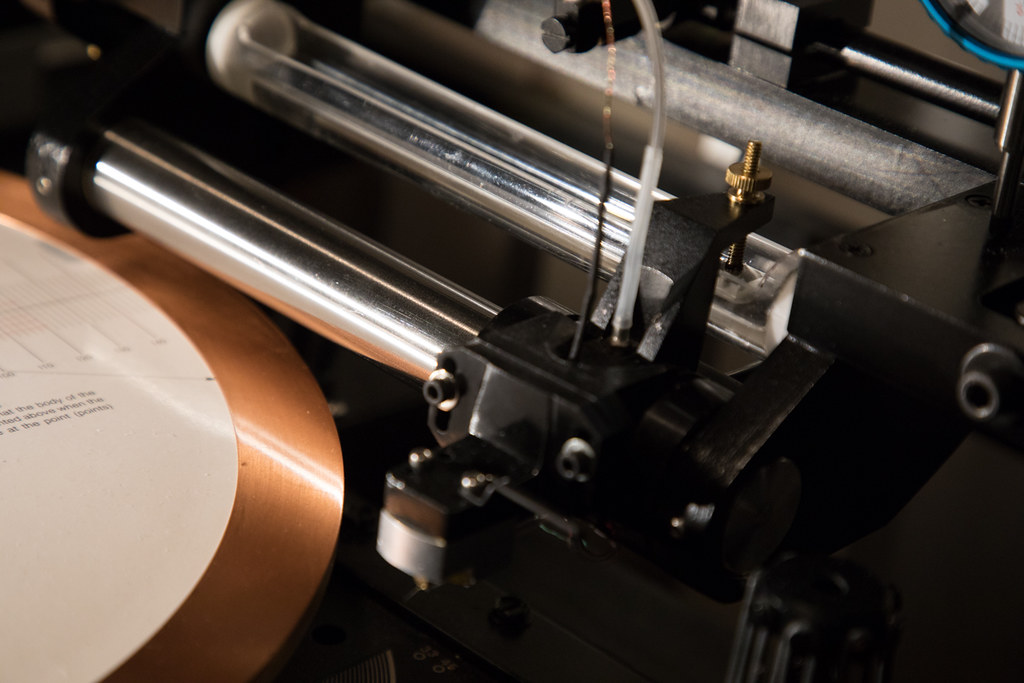

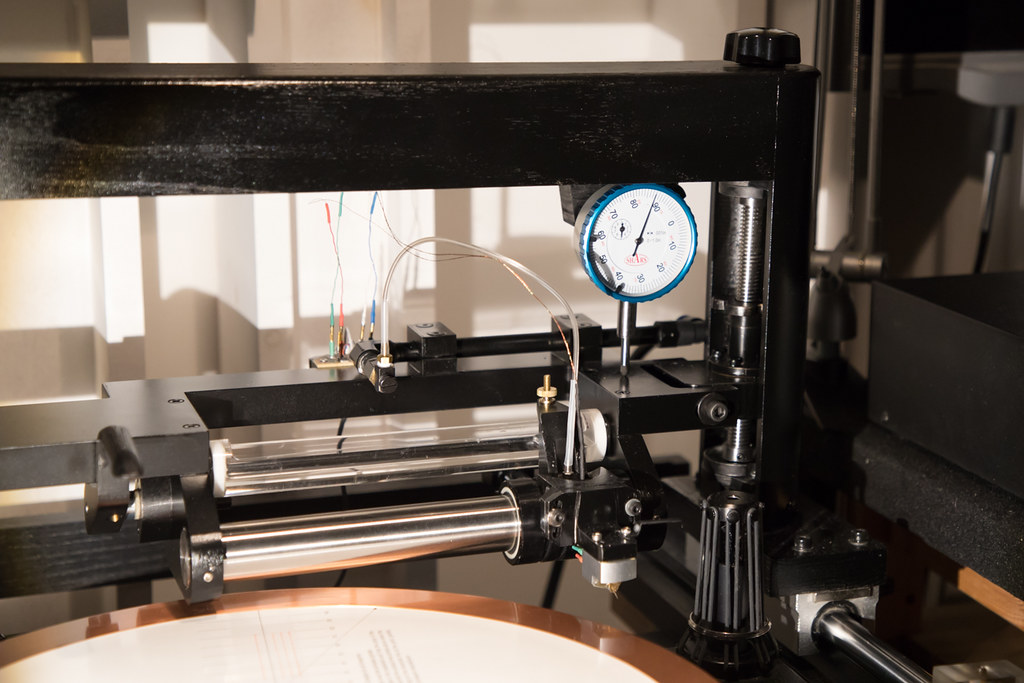

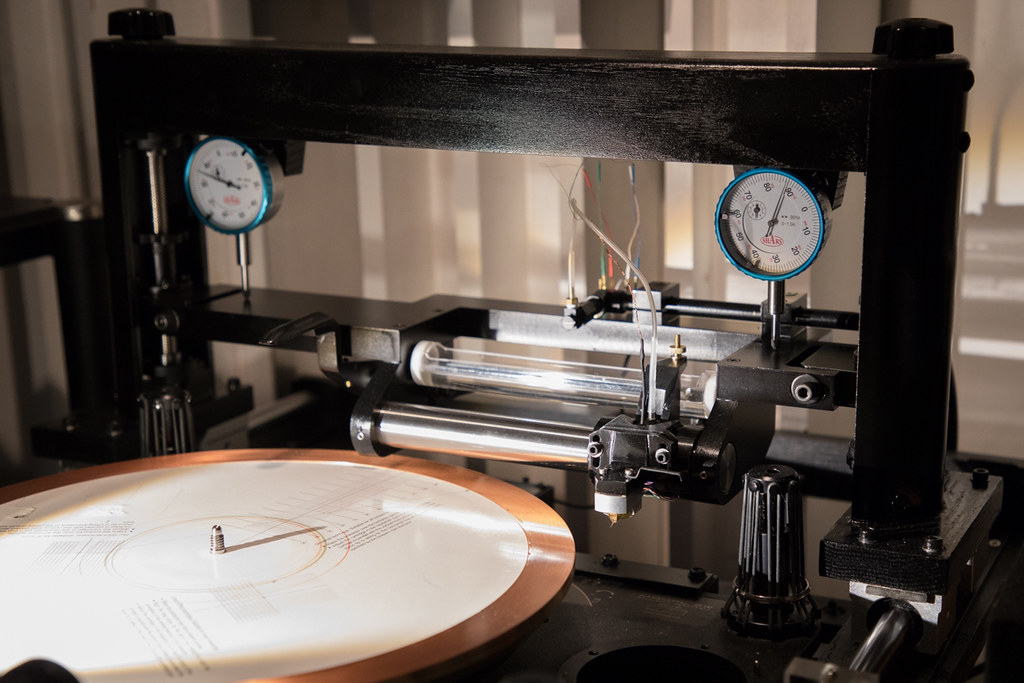

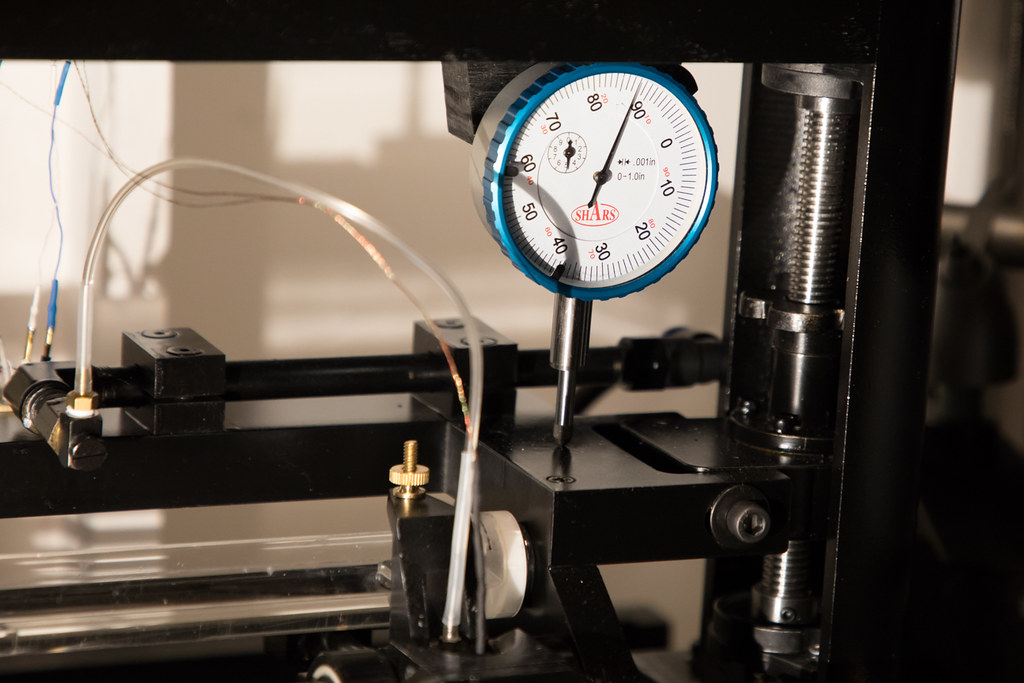

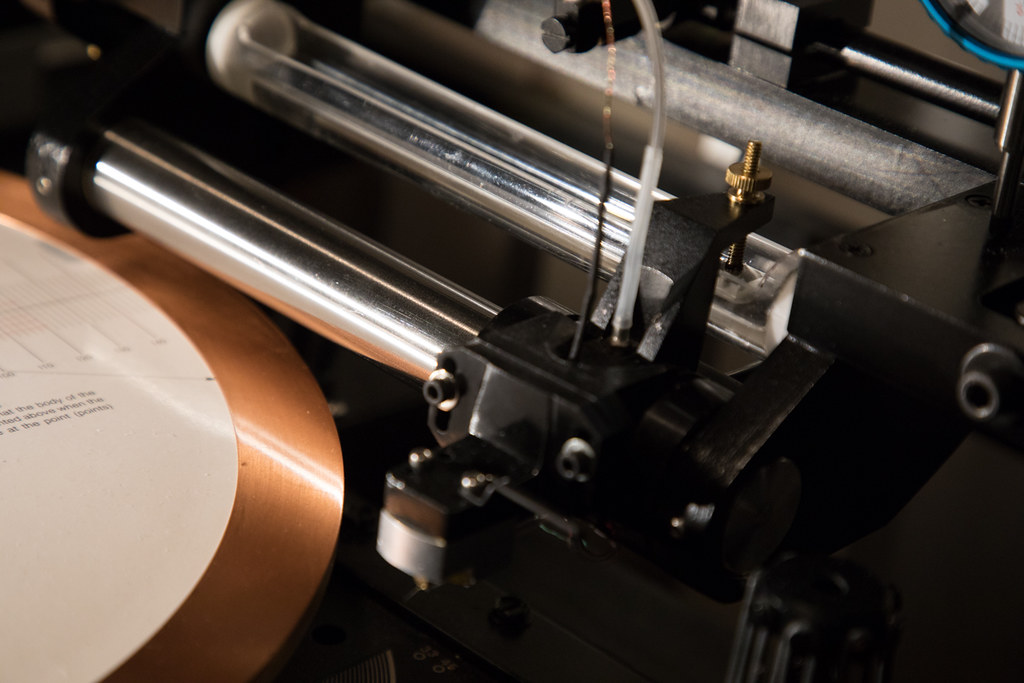

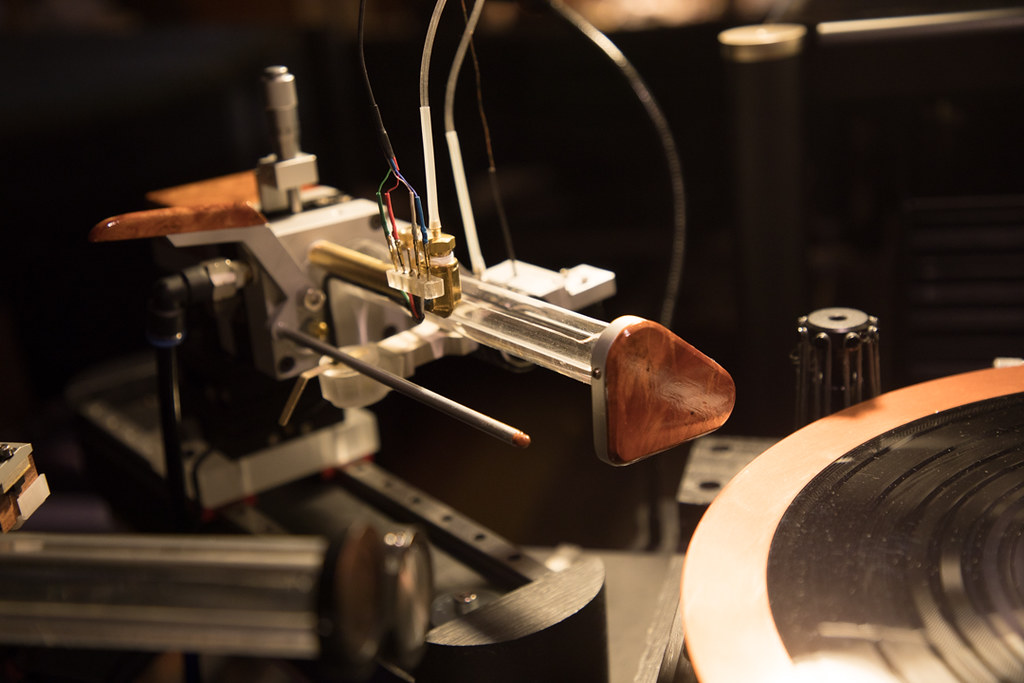

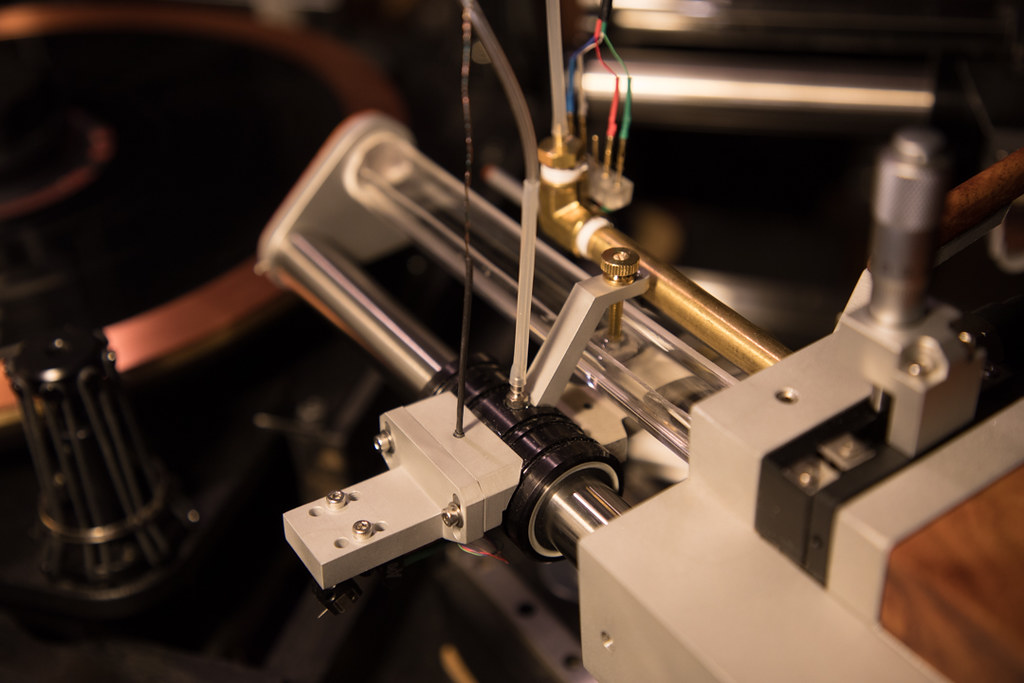

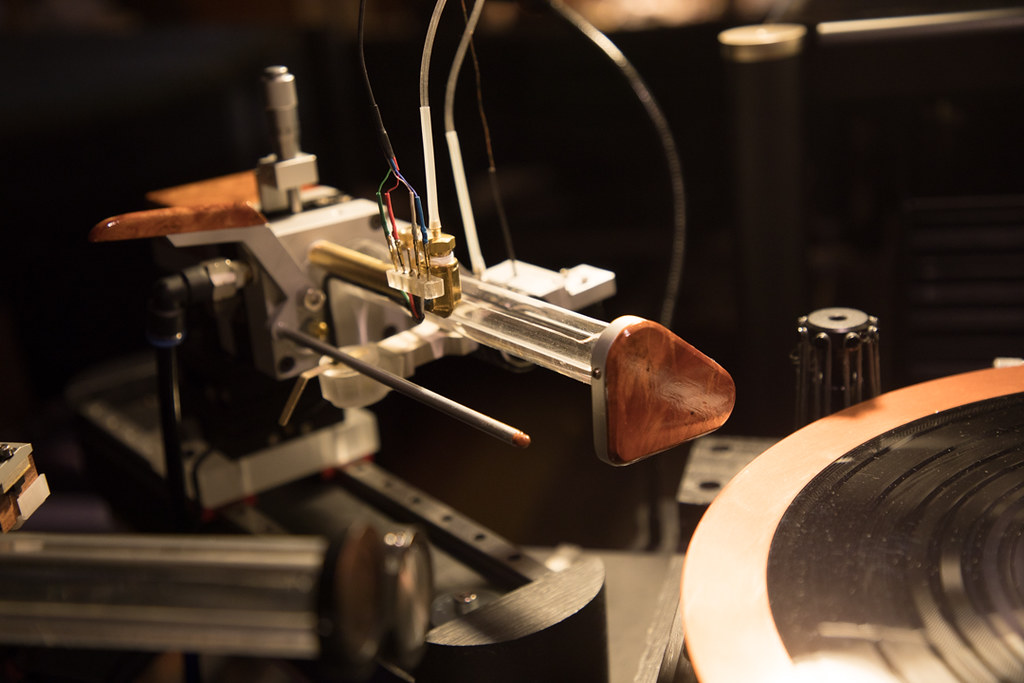

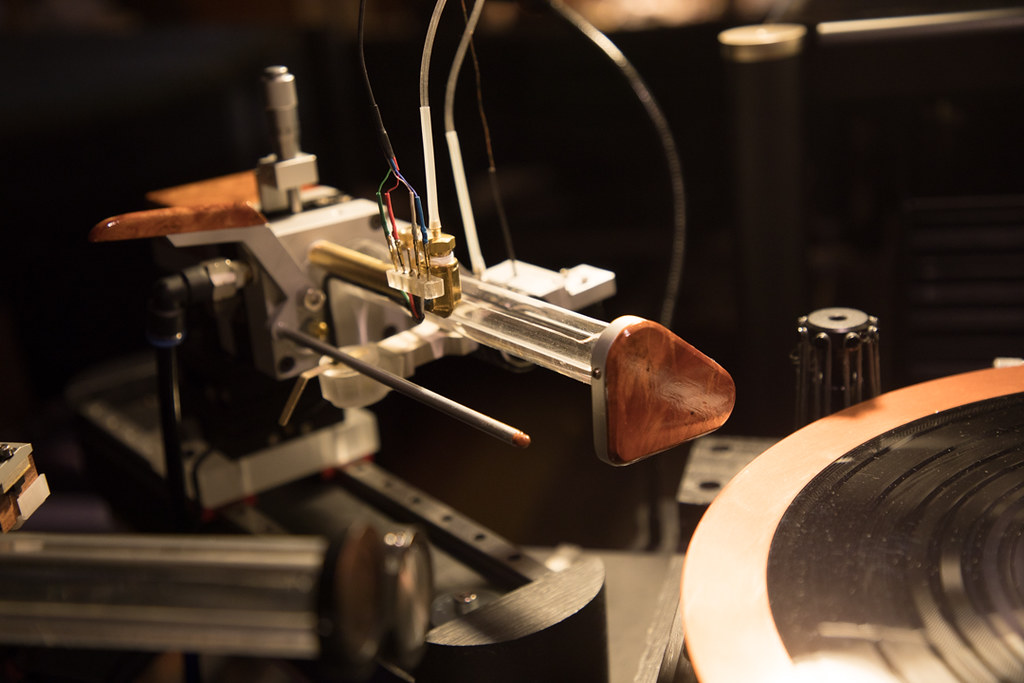

I finished the 2nd arm. Here are some photos. It is very easy to make adjustments on the revised arm as 1st one. I also added a damping though for 2nd arm. For the paddle of silicone damping device, I use plastic in order to raise vertical damping force. VTA adjustments can be done precisely to 0.001 inch and it is so easy to do it. The revised arm sound wonderful with a Sound Smith tipped Denon DL-103R.

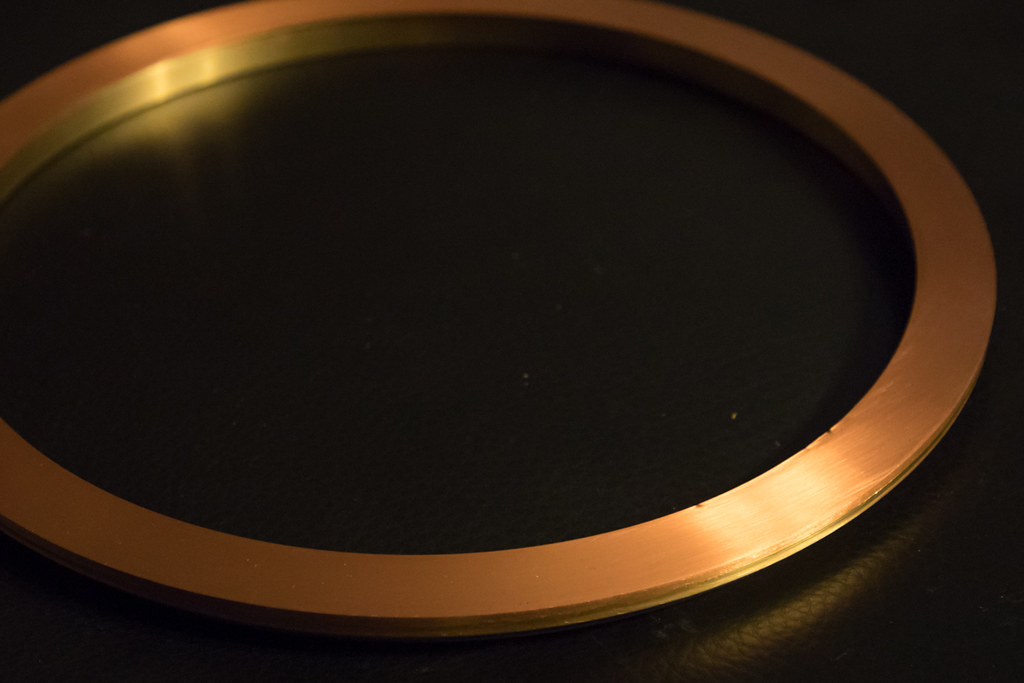

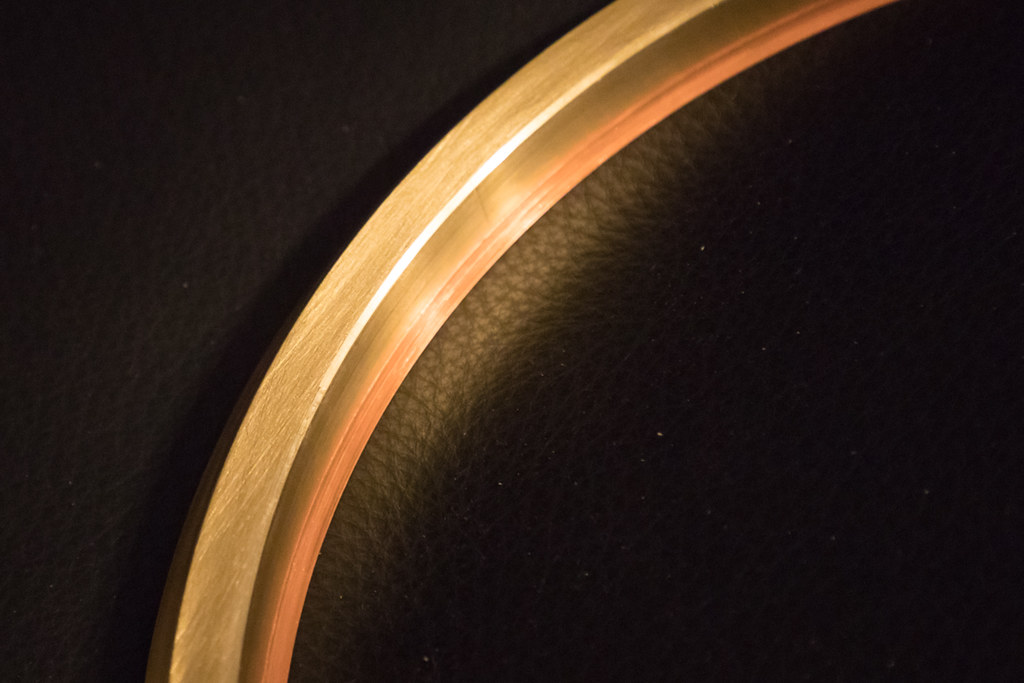

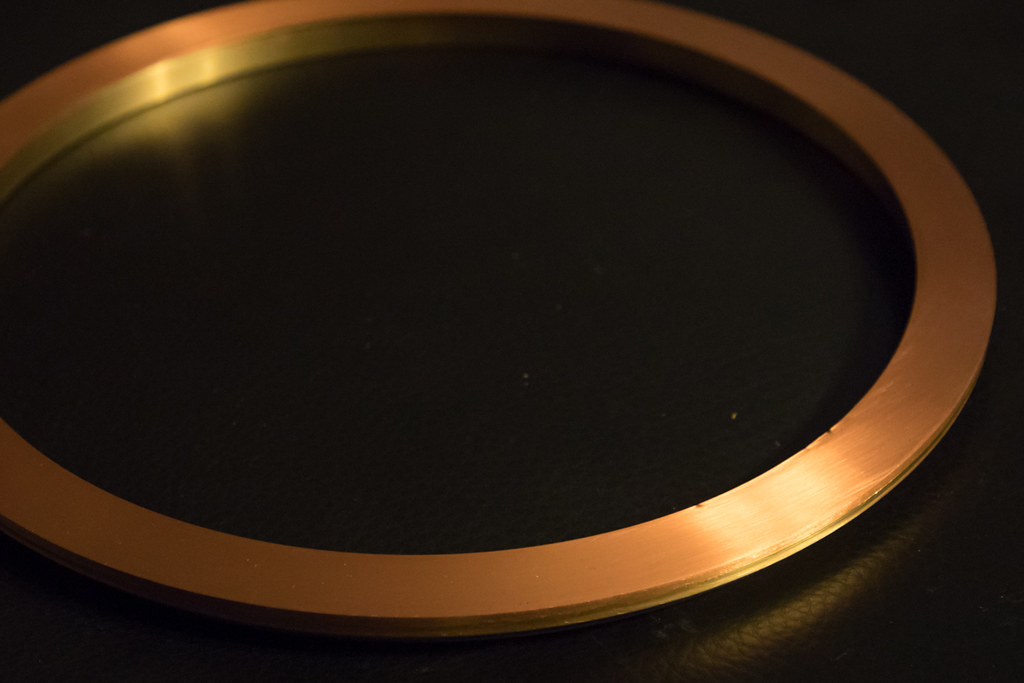

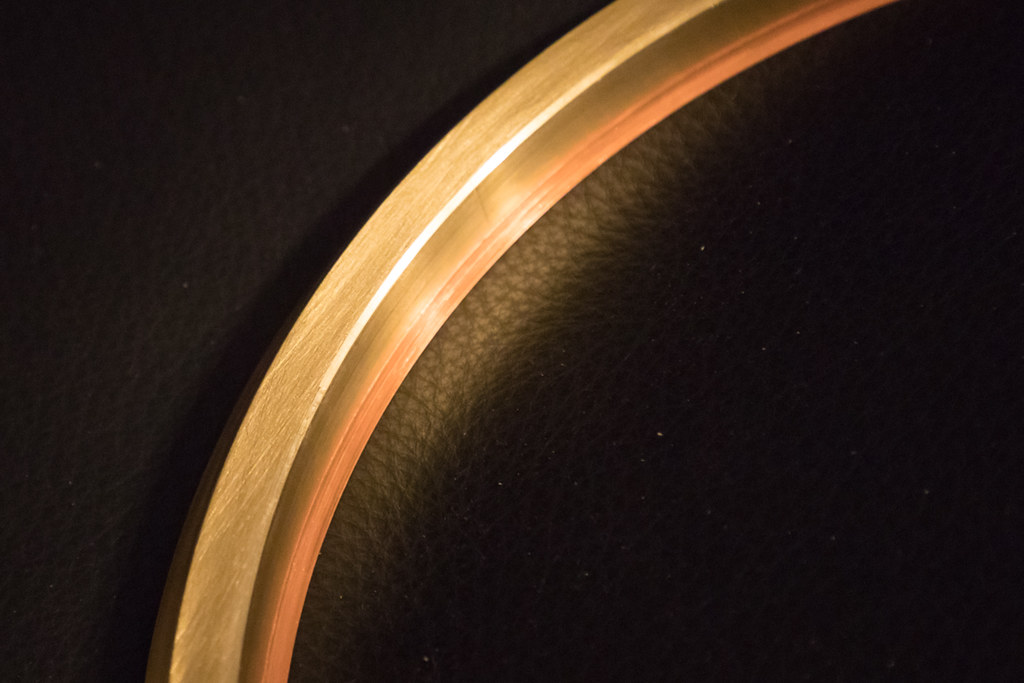

In the meantimes, I also re-designed new outer ring. The old outer ring was about 7 lbs. The new outer ring is 4.5 lbs now. The propose is to improve stability of speed.

I am designing third arm now. The goal is to make 80 grams arm to work with medium compliance cartridges.

However, I couldn’t say the same for another arm. The other arm did sound great, too. It had total mass about 200 grams. It worked very well with low compliance cartridges. It had no damping device and was not easy to make adjustments. So, I decided to modify this arm again.

First, I reduced the arm’s total mass. It is about 170 grams now. I keep this arm in relatively heavy mass because I plan to have three arms with different total masses to work with different cartridges. My plan is to have three arms with 80, 130 and 170 grams respectively. So, I can have wide choice to match different cartridges. Heavy arm usually has better bass.

I finished the 2nd arm. Here are some photos. It is very easy to make adjustments on the revised arm as 1st one. I also added a damping though for 2nd arm. For the paddle of silicone damping device, I use plastic in order to raise vertical damping force. VTA adjustments can be done precisely to 0.001 inch and it is so easy to do it. The revised arm sound wonderful with a Sound Smith tipped Denon DL-103R.

In the meantimes, I also re-designed new outer ring. The old outer ring was about 7 lbs. The new outer ring is 4.5 lbs now. The propose is to improve stability of speed.

I am designing third arm now. The goal is to make 80 grams arm to work with medium compliance cartridges.

Super

How are you improving speed stability with a lighter outer ring? Your originial was 7 lbs. and now 4 1/2 lbs

Maybe a rebalance and less belt slip with less rotational mass as an issue to be solved ?

Excelllent work BTW

Regards

David

Hello David,

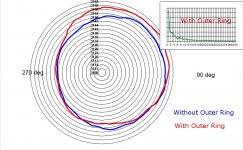

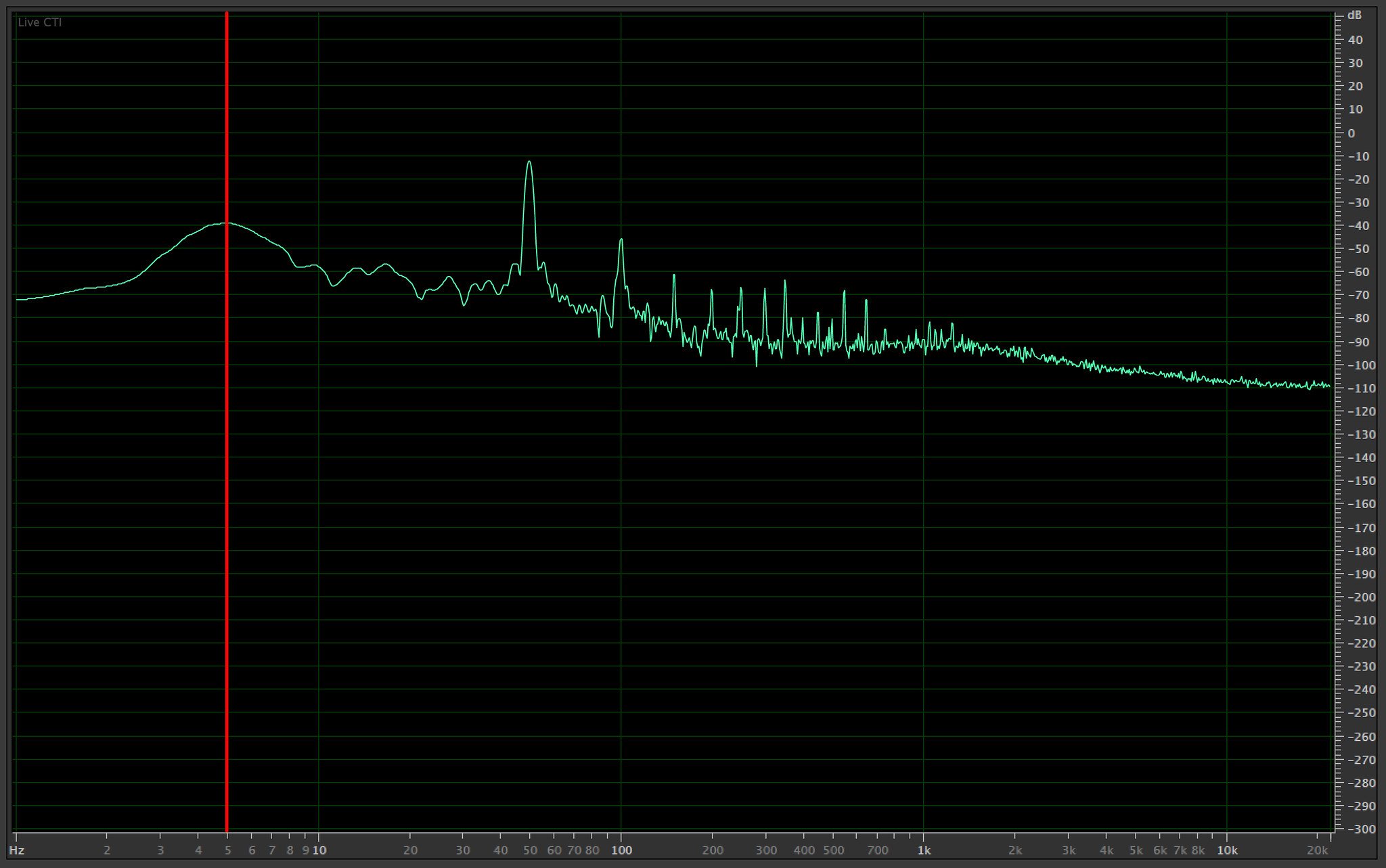

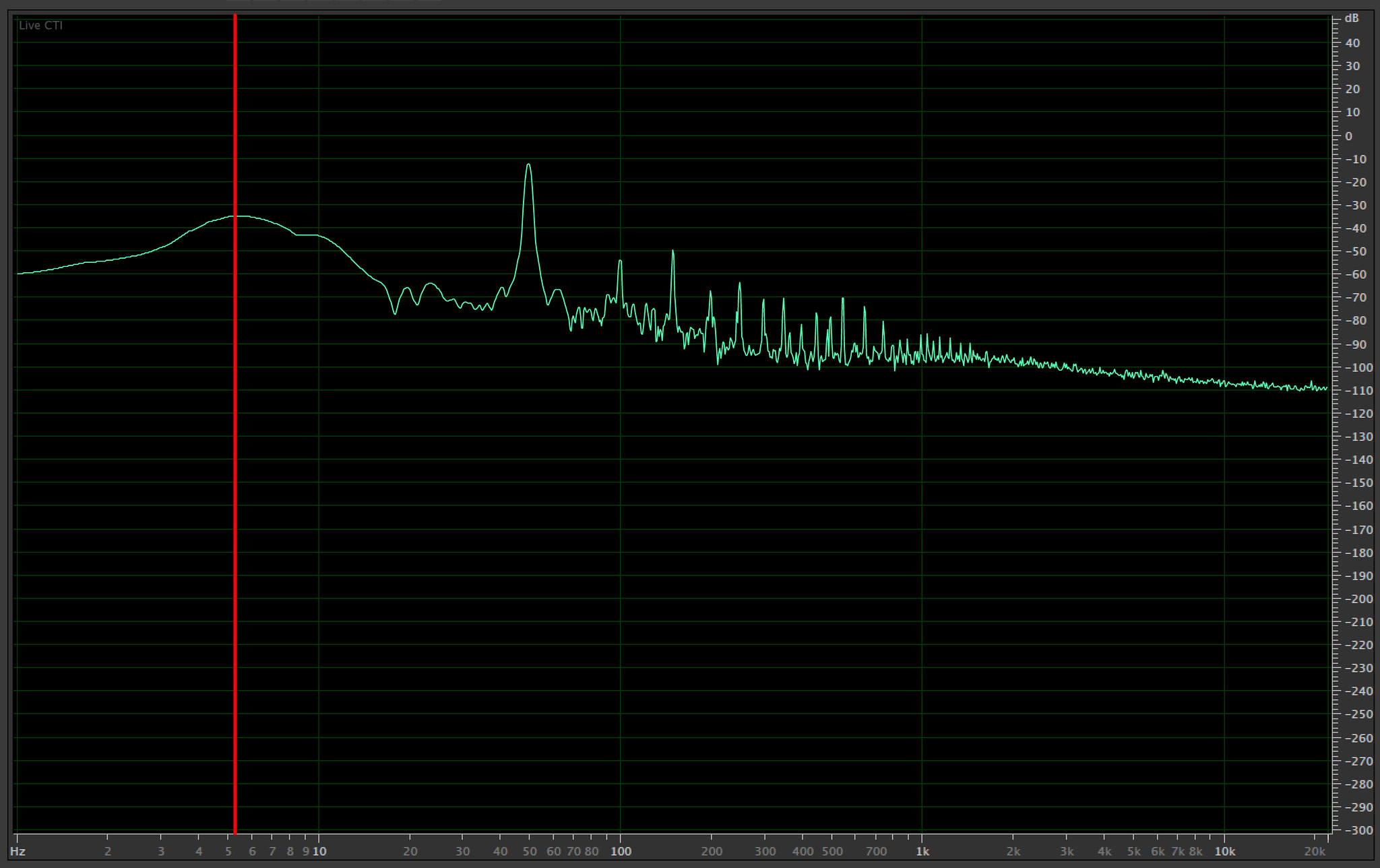

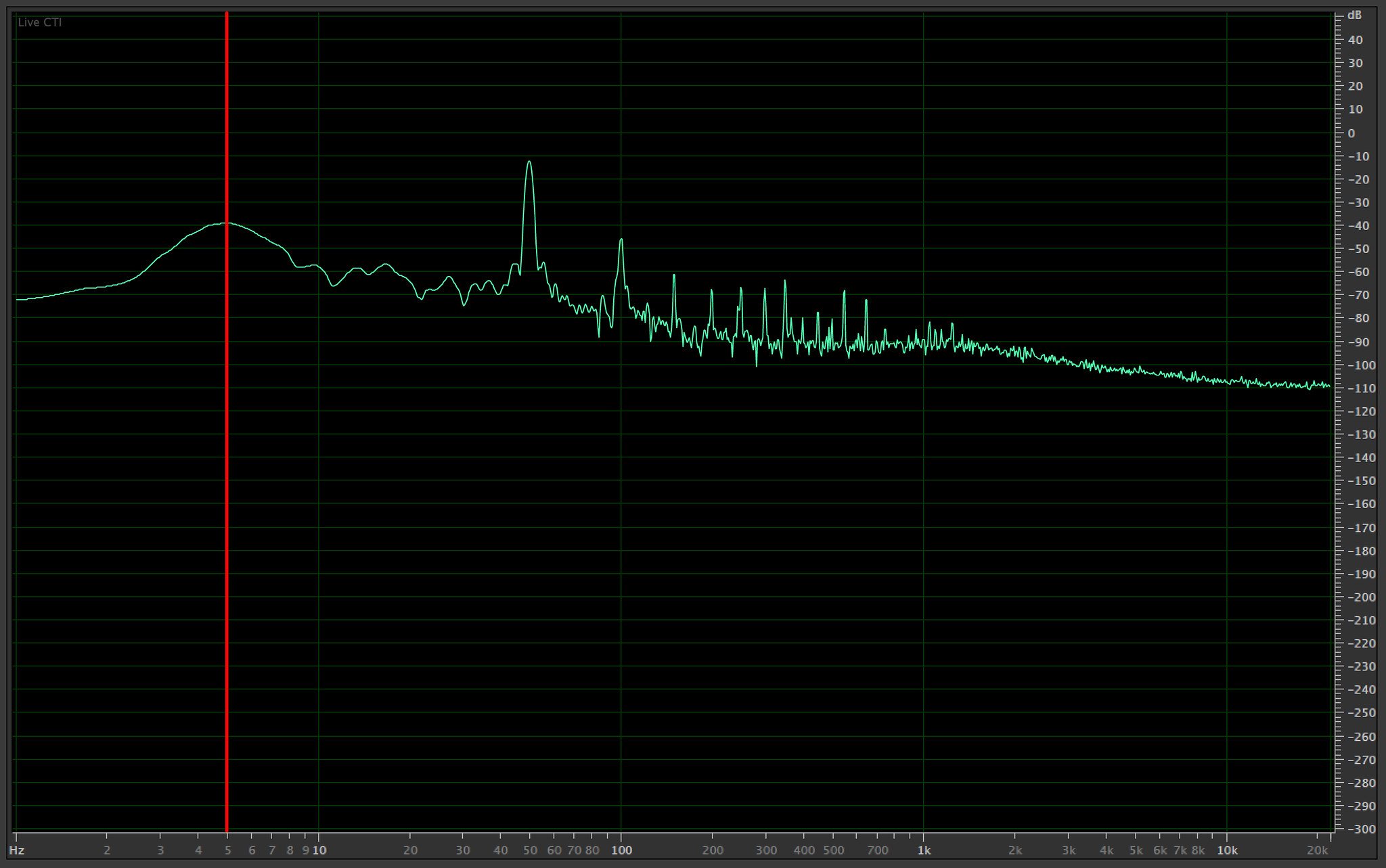

In a different thread, luckythedog did a analysis of my table speed with and without 7 lbs outer ring. Please see attached image for the result of analysis.

You can see that the speed was not as stable as the speed without the outer ring. It is because the weight of outer ring caused this. In order to improve the stability of speed, in my opinions, the weight of outer ring needed to be reduced. I don’t have measurements for the new 4.5 lbs outer ring, but I think it will improve the stability of speed.

Jim

Attachments

Are these graphs showing some off-centering of the test disc?Hello David,

In a different thread, luckythedog did a analysis of my table speed with and without 7 lbs outer ring. Please see attached image for the result of analysis.

You can see that the speed was not as stable as the speed without the outer ring. It is because the weight of outer ring caused this. In order to improve the stability of speed, in my opinions, the weight of outer ring needed to be reduced. I don’t have measurements for the new 4.5 lbs outer ring, but I think it will improve the stability of speed.

Jim

Are these graphs showing some off-centering of the test disc?

Yes. I used The Ultimate Analogue Test LP which is seriously eccentric. I tried to expand the center hole but realized that it involves too much work if I want to correct the eccentricity.

YouTube Video: "Linear tracking tonearm 2 on Technics SP10MK2"

Just saw this new VIDEO that seems to fit in this thread. The arms seems to be nicely done and I like its simplicity. Judging by the blue bushing, it's most likely a New Wave air bearing bushing. The smooth horizontal swaying motion following eccentricity seems to suggest very low friction. I would put the counterweight on the other end of the rod a la ET2 or Walker style, though.

Just saw this new VIDEO that seems to fit in this thread. The arms seems to be nicely done and I like its simplicity. Judging by the blue bushing, it's most likely a New Wave air bearing bushing. The smooth horizontal swaying motion following eccentricity seems to suggest very low friction. I would put the counterweight on the other end of the rod a la ET2 or Walker style, though.

DD,

Thank you for posting the video!

I have some concerns about this air bearing arm.

It looks like the arm has only one air bearing. So, its tolerance may be low. According to New Way air bearing, the pressure inside the air bearing is same everywhere. However, I believe on the both ends of air bearing, the pressure is somewhat lower than the pressure in the middle of the bearing. The actual useable length of a 2 inches long air bearing is shorter than 2 inches. Two air bearings may be ideal for this kind of moving shaft arm.

For a moving shaft air bearing arm, material of shaft is very critical since a solid round shaft will increase moving mass considerably. To my experience, 200 g moving mass is probably up limit for air bearing arms. A precision ceramic hollow shaft is ideal. However, it is very expensive to custom make one. It is almost out reach for diyers.

Thank you for posting the video!

I have some concerns about this air bearing arm.

It looks like the arm has only one air bearing. So, its tolerance may be low. According to New Way air bearing, the pressure inside the air bearing is same everywhere. However, I believe on the both ends of air bearing, the pressure is somewhat lower than the pressure in the middle of the bearing. The actual useable length of a 2 inches long air bearing is shorter than 2 inches. Two air bearings may be ideal for this kind of moving shaft arm.

For a moving shaft air bearing arm, material of shaft is very critical since a solid round shaft will increase moving mass considerably. To my experience, 200 g moving mass is probably up limit for air bearing arms. A precision ceramic hollow shaft is ideal. However, it is very expensive to custom make one. It is almost out reach for diyers.

In the video where he has all the mass on one end means you have to run an extreme amount of air pressure because of imbalance in weight across the air bearing.

I did the same thing many moons ago with a purchased Maplenoll air bearing assembly only to find out it would stick without increasing air pressure and I mean substantially more.

More air pressure means more noise potentially

You will note all the Maplenoll versions and others balance out the mass on both sides for this reason.

The arm in the video has too much horizontal mass anyway and no real benefit is gained doing it this way

Regards

David

I did the same thing many moons ago with a purchased Maplenoll air bearing assembly only to find out it would stick without increasing air pressure and I mean substantially more.

More air pressure means more noise potentially

You will note all the Maplenoll versions and others balance out the mass on both sides for this reason.

The arm in the video has too much horizontal mass anyway and no real benefit is gained doing it this way

Regards

David

David,

It is very legit concern, especially, when the tolerance is low or the air pressure is low. If two air bearings with high pressure, such concern may not be a problem. However, using two air bearings may require longer shaft. Therefore, moving mass may increase as well. In addition to what I said above, I found large size of air bearing is better than small air bearing. If both air bearings are large size, its moving shaft will increase its mass, too.

Jim

It is very legit concern, especially, when the tolerance is low or the air pressure is low. If two air bearings with high pressure, such concern may not be a problem. However, using two air bearings may require longer shaft. Therefore, moving mass may increase as well. In addition to what I said above, I found large size of air bearing is better than small air bearing. If both air bearings are large size, its moving shaft will increase its mass, too.

Jim

There is another concern for moving shaft air bearing arm.

Let’s compare Walker’s arm with this arm. For this arm, when cartridge moves to inner groove of record, its shaft is all the way out of air bushing. The shaft is highly prone to vibration at that position. For Walker Audio’s arm, when the cartridge moves to inner groove of record, its shaft moves all the way into air bushing. The shaft is less prone to vibration. We all know that it is difficult to play inner groove. So, the shaft on Walker’s arm is in better position to play inner groove, but not for the arm in the Youtube video.

I think the layout of Walker's arm is better than the one in video.

Now, let’s compare moving shaft and moving bearing arms. Moving bearing arm doesn’t have all the problems I mentioned above except air supply tubing may cause problem if the tubing has too much resistance. If the right air supply tubing is used, there will be no problem at all. This is why I think moving bearing is superior to moving shaft air bearing arm.

Let’s compare Walker’s arm with this arm. For this arm, when cartridge moves to inner groove of record, its shaft is all the way out of air bushing. The shaft is highly prone to vibration at that position. For Walker Audio’s arm, when the cartridge moves to inner groove of record, its shaft moves all the way into air bushing. The shaft is less prone to vibration. We all know that it is difficult to play inner groove. So, the shaft on Walker’s arm is in better position to play inner groove, but not for the arm in the Youtube video.

I think the layout of Walker's arm is better than the one in video.

Now, let’s compare moving shaft and moving bearing arms. Moving bearing arm doesn’t have all the problems I mentioned above except air supply tubing may cause problem if the tubing has too much resistance. If the right air supply tubing is used, there will be no problem at all. This is why I think moving bearing is superior to moving shaft air bearing arm.

Last edited:

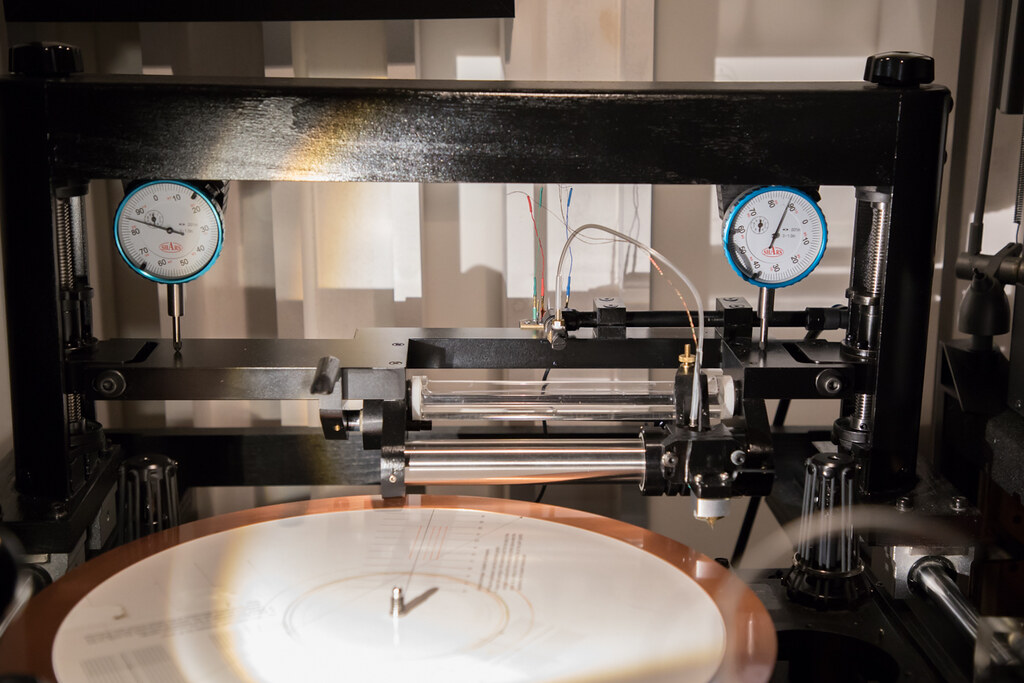

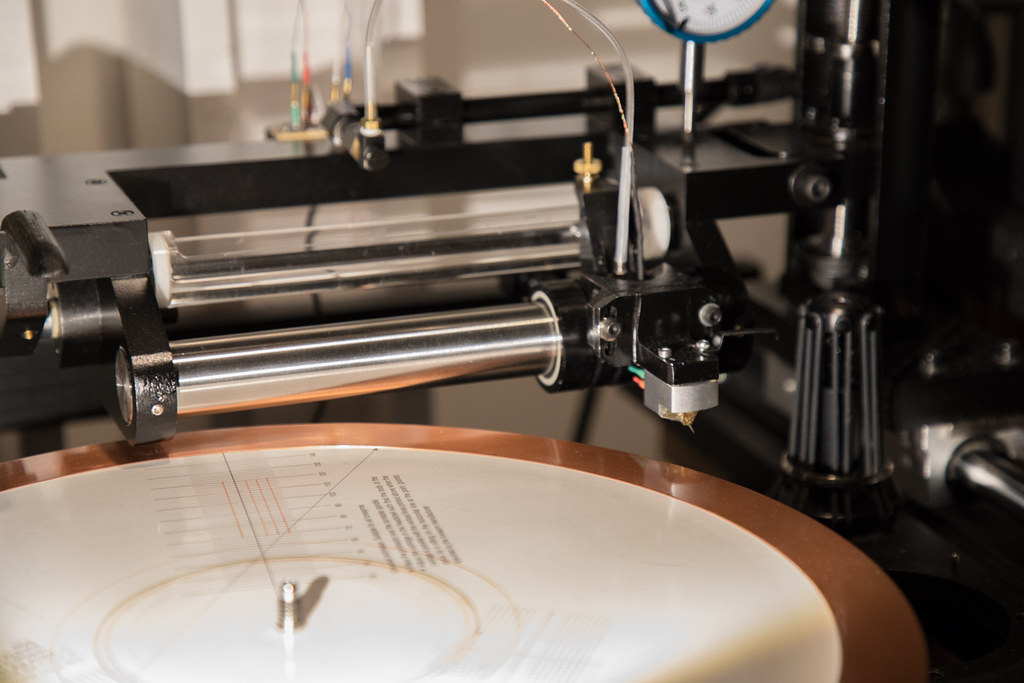

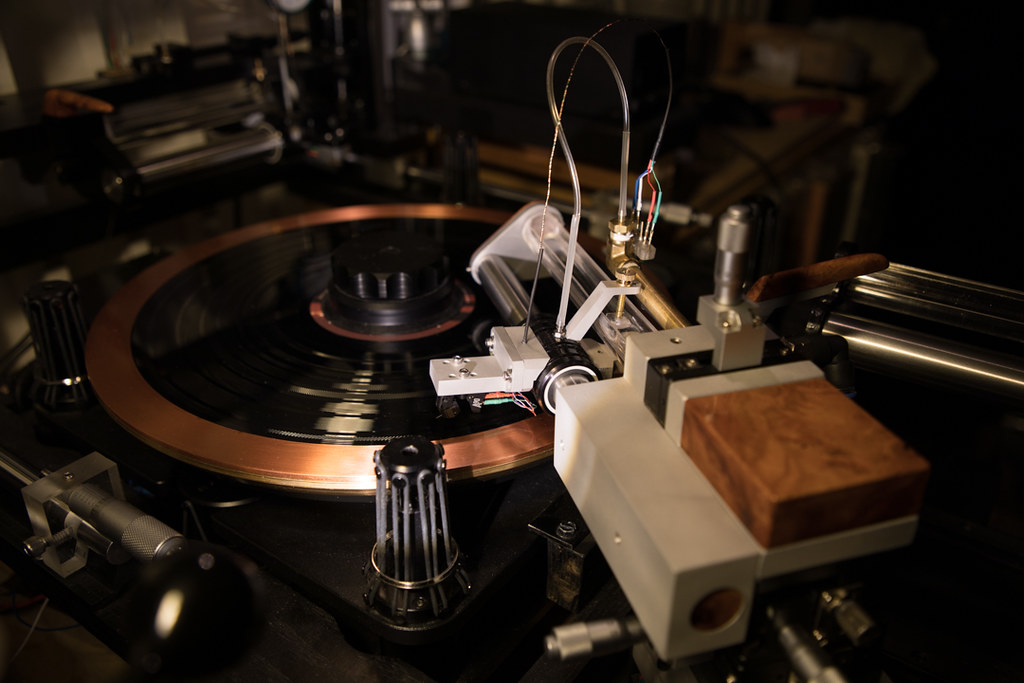

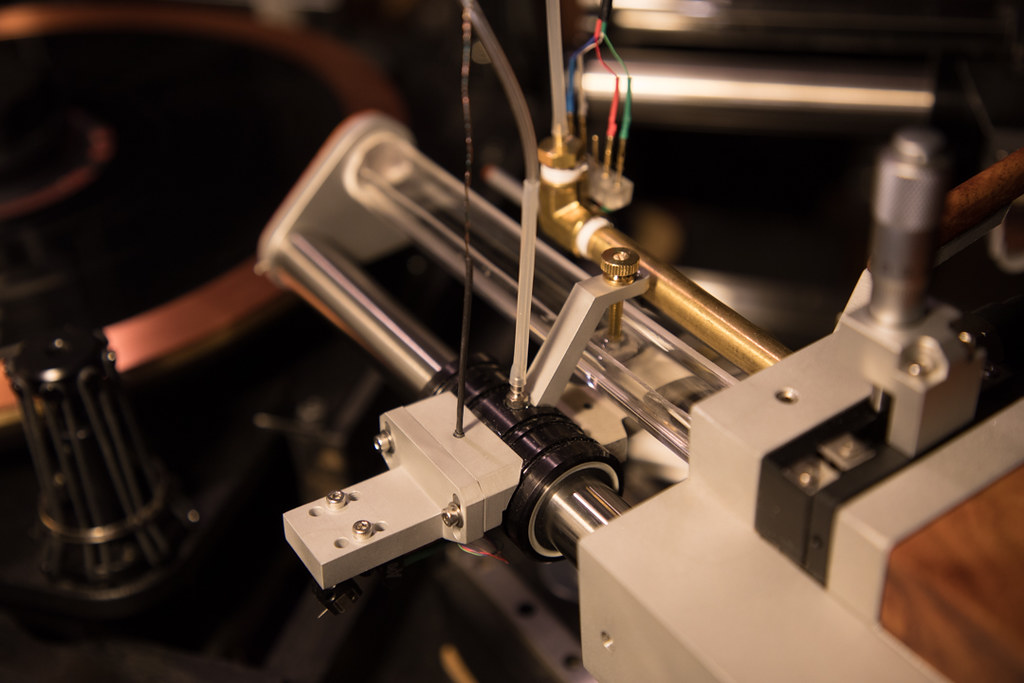

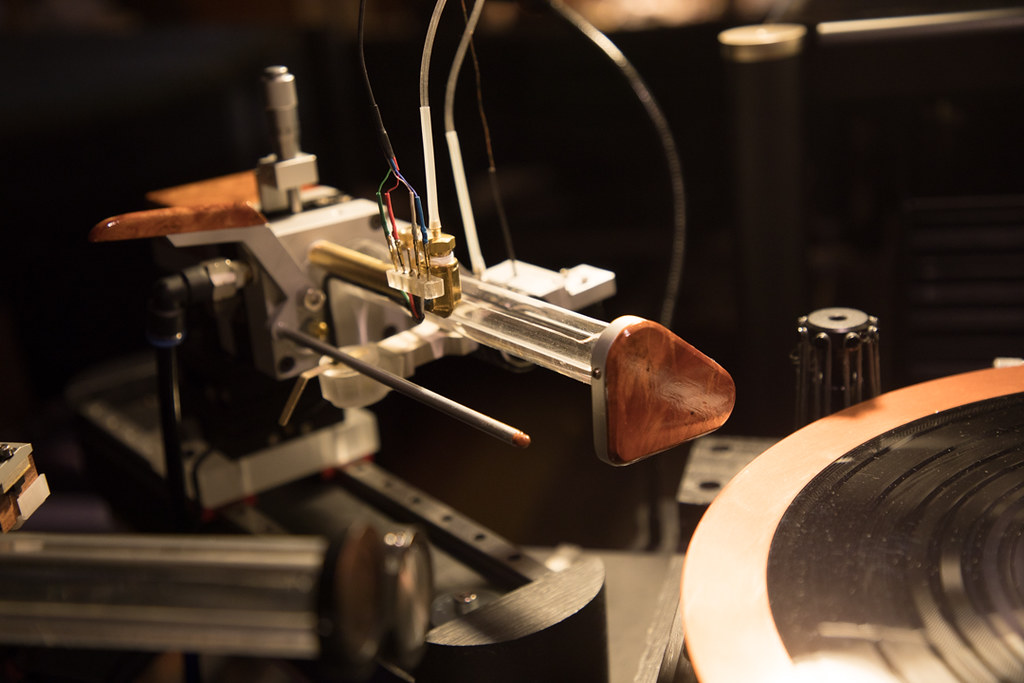

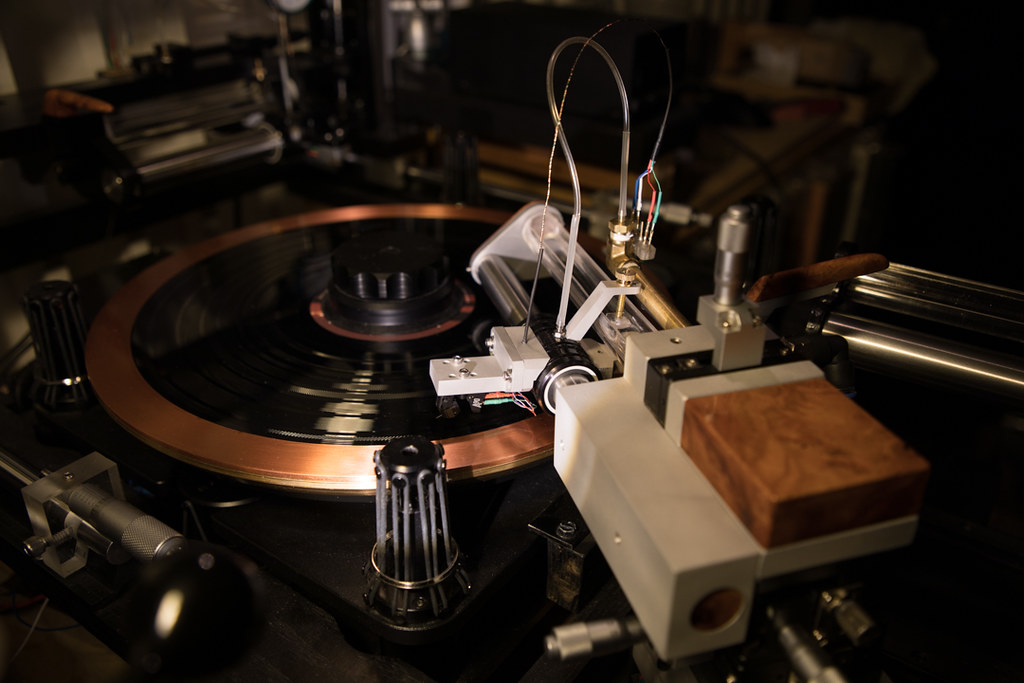

I just finished another air bearing arm.

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr

For this arm, I designed it specially for two cartridges I have, Ortofon A90 and Benz LPs. Both are medium compliance cartridges. The total mass of carriage I designed should be 80 arms, however, the actual weight of the carriage is 98 grams which is 18 grams heavier than I designed due to some mis-calculation.

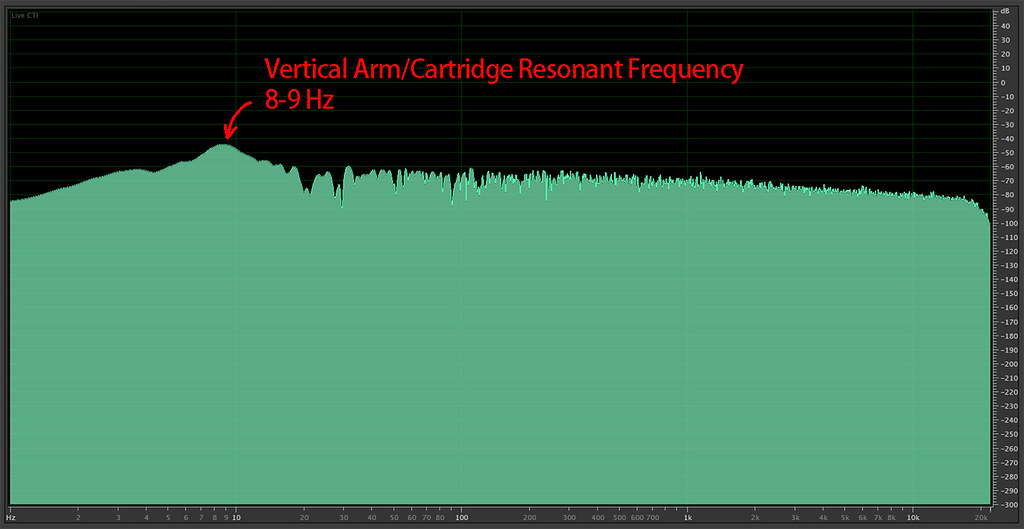

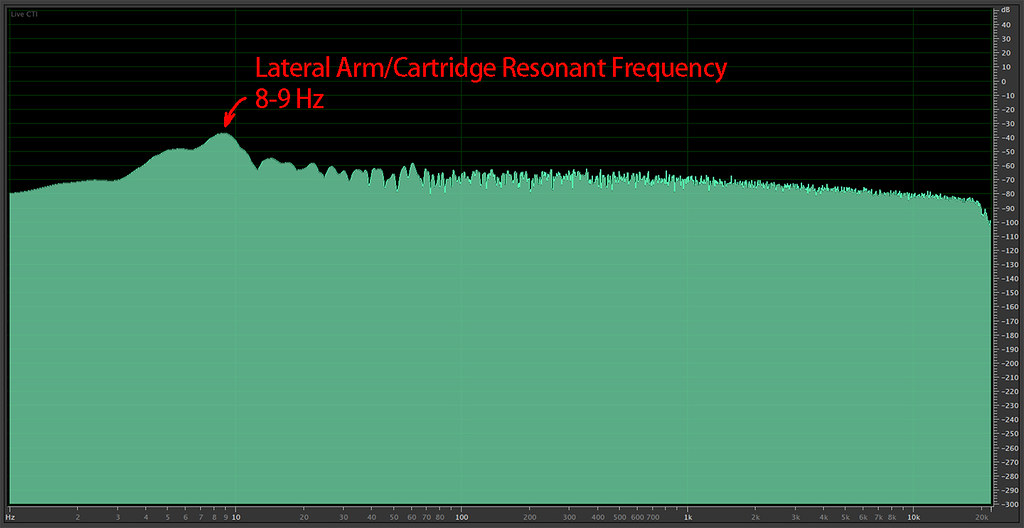

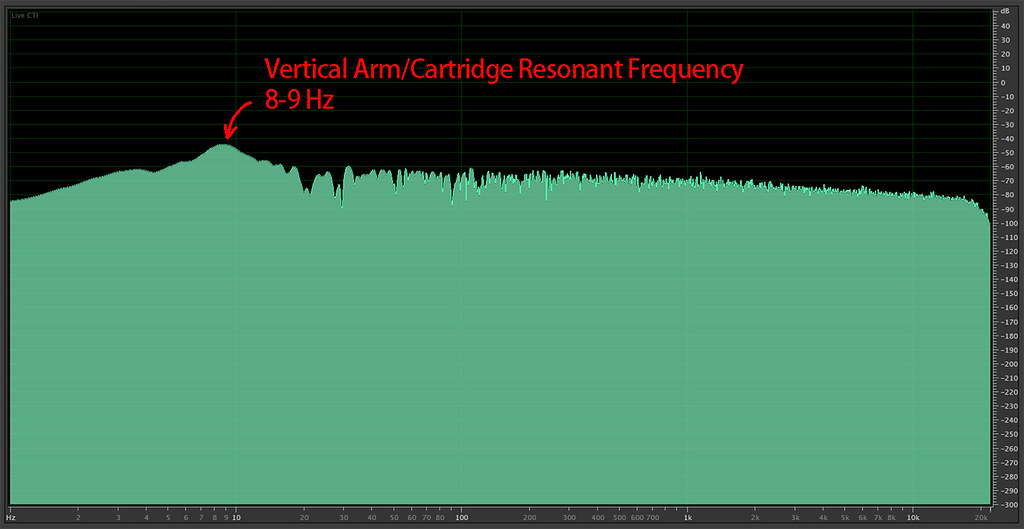

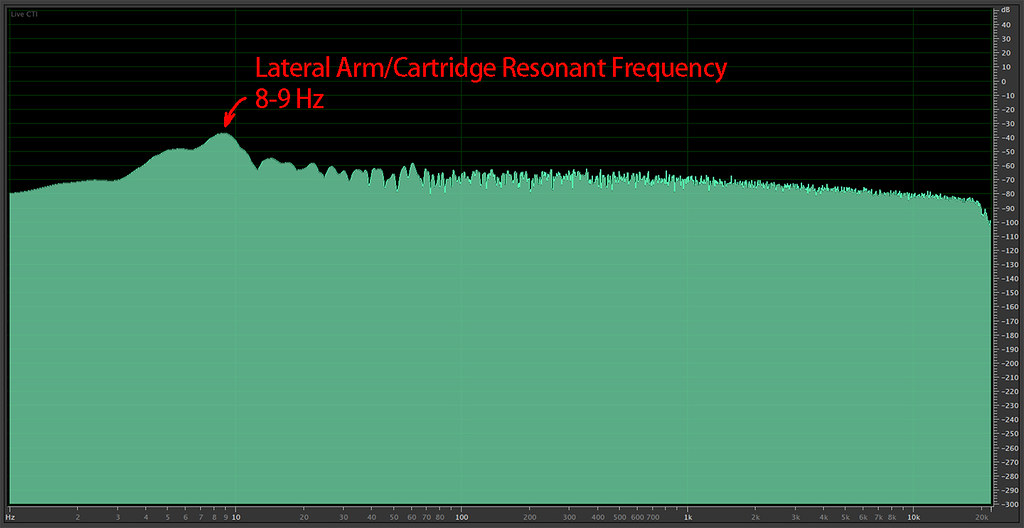

I tested arm/cartridge resonate frequency for this new arm. Its vertical and lateral are both within 8-9 Hz, which is almost perfect. If it is 80 grams, it may well hit the ideal spot, 10-12 Hz. Anyway, I am very happy with the result.

Here is a question I would like to know the answer. Consensus is arm/cartridge resonate frequency should be ideally within 7-12 Hz. I can understand its upper limit but not its low limit. My other two arms have resonate frequencies both 3-4 Hz vertically and laterally. But I have never had any problems at all.

vertical pink by Jim Wang, on Flickr

vertical pink by Jim Wang, on Flickr

lateral pink by Jim Wang, on Flickr

lateral pink by Jim Wang, on Flickr

After serval listening sessions, I can tell that the arm has superior track-ability although I haven’t tested it yet and is extremely quiet.

This arm reflects everything I know to design and built an air bearing arm. This is probably the last air bearing arm I built because not only I have explored many options for air bearing arms but also my interest has been changed from audio to oil painting. I learnt Chinese painting when I was in high school. I am learning oil painting and is having a lot of fun now. Passion for fine art is always in my blood.

Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on Flickr Untitled by Jim Wang, on Flickr

Untitled by Jim Wang, on FlickrFor this arm, I designed it specially for two cartridges I have, Ortofon A90 and Benz LPs. Both are medium compliance cartridges. The total mass of carriage I designed should be 80 arms, however, the actual weight of the carriage is 98 grams which is 18 grams heavier than I designed due to some mis-calculation.

I tested arm/cartridge resonate frequency for this new arm. Its vertical and lateral are both within 8-9 Hz, which is almost perfect. If it is 80 grams, it may well hit the ideal spot, 10-12 Hz. Anyway, I am very happy with the result.

Here is a question I would like to know the answer. Consensus is arm/cartridge resonate frequency should be ideally within 7-12 Hz. I can understand its upper limit but not its low limit. My other two arms have resonate frequencies both 3-4 Hz vertically and laterally. But I have never had any problems at all.

vertical pink by Jim Wang, on Flickr

vertical pink by Jim Wang, on Flickr lateral pink by Jim Wang, on Flickr

lateral pink by Jim Wang, on FlickrAfter serval listening sessions, I can tell that the arm has superior track-ability although I haven’t tested it yet and is extremely quiet.

This arm reflects everything I know to design and built an air bearing arm. This is probably the last air bearing arm I built because not only I have explored many options for air bearing arms but also my interest has been changed from audio to oil painting. I learnt Chinese painting when I was in high school. I am learning oil painting and is having a lot of fun now. Passion for fine art is always in my blood.

Last edited:

I believe the lower bound is there for suspended decks so there's no interaction

with the suspension frequency, typical 5hz

Also the record spins at nearly 2Hz, so an off center or warped LP will be a problem

with a very low resonant frequency arm.

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm