That's cool, willybig! Sounds professional!

Mine is made 100% by hand, so far! (except for a few commercially made bolted on bits, like slideways, and feed screw!)

I've been building in my spare time for many months now! Hopefully I can do my first proper cut within the next couple of weeks! (mono, non feedback)

It looks like it will be a constantly developing project over the next year or so!

It would be interesting to see how you go!

... Steve, aka loonatron

Mine is made 100% by hand, so far! (except for a few commercially made bolted on bits, like slideways, and feed screw!)

I've been building in my spare time for many months now! Hopefully I can do my first proper cut within the next couple of weeks! (mono, non feedback)

It looks like it will be a constantly developing project over the next year or so!

It would be interesting to see how you go!

... Steve, aka loonatron

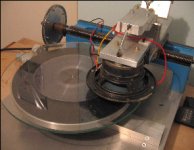

Here's a pic from several months ago... I did some test cuts... sounded bad! (But it was interesting!) But now I have some proper dubplates, and styli... Now I have to buy or build a proper cutterhead, and find a proper amp from somewhere... as well as build a better turntable. (experiments were with technics SL1210... TT in photo is a mockup!)

Attachments

For those wondering what happened to the record cutting machines in Australia, the last were sold by Philips in the mid-90s and bought by a Victorian company, Corduroy. They are the only people, I believe, still making vinyl commercially. They are Corduroy Records in Highett, Vic.

Hey Aaron,

Thanks for taking a look! Nah, I haven't done any more work. I got a new job a few months ago, and now I spend 3 hours a day travelling to and from work. I also started studying electronics two nights a week... so I don't know when I'll get to play with this project again... maybe when I get some annual leave or something...

Hey Natsirt,

that's really interesting!

all the best, from Steve

Thanks for taking a look! Nah, I haven't done any more work. I got a new job a few months ago, and now I spend 3 hours a day travelling to and from work. I also started studying electronics two nights a week... so I don't know when I'll get to play with this project again... maybe when I get some annual leave or something...

Hey Natsirt,

that's really interesting!

all the best, from Steve

Hey loonatron, I owned a vinyl cutter, used at the time for cutting dubplates (acetates) for playing on my own sound system, and as a service for local DJ's. The unit was called a kingston, made by vinylium, based in Switzerland. Ours was the first in the UK, an early model which has probably been refined since...cost us about 4ooo english pounds, the price has probably gone up now though. The guys at Vinylium used to supply heads(The designer of the kingston, Flo, is the european Neumann engineer and the head is the same as on a neumman lathe), if you still fancy Diying such a machine, you'll need a very stable platter to keep that disk spinning at a constant speed. You'll eat diamond cutting styli at 80pounds a piece too...If you're still into the idea look them up...

And to whoever suggested it, i don't think a second hand Neumann would be cheaper...they fetch 25-50grand!

And to whoever suggested it, i don't think a second hand Neumann would be cheaper...they fetch 25-50grand!

Hi jethdub,

I didn't know that you could get diamond cutting styli for the kingston. I thought you could only use sapphire cutting styli, on normal dubplates. (like the ones from Transco or Appollo, that only last so many plays)

Unfortunately, I've had to put this project aside, I'm studying and working too much! (but learning about power amplifiers, which could come in handy later!)

Kaicutz,

I don't remember the answer to these details, it was nearly 18months since I looked into this stuff... but my dodgy cutterhead had an adjustable counterweight to adjust the tension on the spring that the cutterhead is suspended from. When making cuts, the literature I have seen refers to depth of cut, rather than weight or pressure on the cutting stylus.

All the best, from Steve

P.S. does anyone know where the ex 2GB (Sydney) cutting system ended up? It was up for sale recently

I didn't know that you could get diamond cutting styli for the kingston. I thought you could only use sapphire cutting styli, on normal dubplates. (like the ones from Transco or Appollo, that only last so many plays)

Unfortunately, I've had to put this project aside, I'm studying and working too much! (but learning about power amplifiers, which could come in handy later!)

Kaicutz,

I don't remember the answer to these details, it was nearly 18months since I looked into this stuff... but my dodgy cutterhead had an adjustable counterweight to adjust the tension on the spring that the cutterhead is suspended from. When making cuts, the literature I have seen refers to depth of cut, rather than weight or pressure on the cutting stylus.

All the best, from Steve

P.S. does anyone know where the ex 2GB (Sydney) cutting system ended up? It was up for sale recently

hmv record cutter

yes i saw this record cutter on ebay the other day, i wonder if it could be re designed using original equipment to cut all types of records, apparently it has a box of blank discs, plastic on aluminium and still works, it is priced at AU1500 I have some interest in buying this item, can anyone tell me if I could doctor it to do what i want it to do? i also found this website with all the specs on the unit. www.coutant.org/hmv2300/

yes i saw this record cutter on ebay the other day, i wonder if it could be re designed using original equipment to cut all types of records, apparently it has a box of blank discs, plastic on aluminium and still works, it is priced at AU1500 I have some interest in buying this item, can anyone tell me if I could doctor it to do what i want it to do? i also found this website with all the specs on the unit. www.coutant.org/hmv2300/

You would have to check the vinylium website, but I thought that they had released some modifications to allow the Kingston cutter to cut long life disks on a special plastic formula..similar to the vestax cutter (Though I heard the vestax cuts never sounded too good..the kingston could produce some nice cuts with practice and sensibly mixed source material..avoid over enhanced subs and in particular excessive peaks in the upper treble range..any sibilance was always a problem that was exaggerated on the cut and could blow the cutter head fuses)... Though the cutter styli were sapphire for standard dubplate cuts, I believe the new disk material requires diamond styli...even more costly.

Is the cutter on e-bay in the UK.?..It could be ours if so, as I'm living in mexico temporarily and my partner had agreed to sell the unit...We just never had the time to really work with it.

Is the cutter on e-bay in the UK.?..It could be ours if so, as I'm living in mexico temporarily and my partner had agreed to sell the unit...We just never had the time to really work with it.

yo loonatron

Hi all,

Loonatron I live on the Central Coast of NSW (about an hour north of you) and I'm extremely interested in doing the same thing as you, although I'm kinda getting a bit discouraged.

I'm interested in cutting my own vinyl and would like to know how your progress is going. Please inform us all...

Hi all,

Loonatron I live on the Central Coast of NSW (about an hour north of you) and I'm extremely interested in doing the same thing as you, although I'm kinda getting a bit discouraged.

I'm interested in cutting my own vinyl and would like to know how your progress is going. Please inform us all...

Hi Jippers,

Hey, its cool that there is someone close by that is probably almost as crazy as me. Unfortunately I don't have the time to work on this little project anymore, I'd also have to buy a small metal machining lathe to finish it off. (don't have access to one anymore) So now its become a bit of a weird art piece.

BTW if putting your tracks onto disc is what you want, there are people who can do that for you. (unfortunately you may have to look overseas, but there are websites that claim quick turn arounds at good prices)

...Steve

Hey, its cool that there is someone close by that is probably almost as crazy as me. Unfortunately I don't have the time to work on this little project anymore, I'd also have to buy a small metal machining lathe to finish it off. (don't have access to one anymore) So now its become a bit of a weird art piece.

BTW if putting your tracks onto disc is what you want, there are people who can do that for you. (unfortunately you may have to look overseas, but there are websites that claim quick turn arounds at good prices)

...Steve

Hi Loonatron

I built and run the vinyl pressing plant in Sydney.

You might want to come down and check it out.

or

www.vinylfactory.com.au

Best

Andy

I built and run the vinyl pressing plant in Sydney.

You might want to come down and check it out.

or

www.vinylfactory.com.au

Best

Andy

vinyl record cutting

I use a home-made vinyl cutting system(not made by myself). I am not an engineer but I have a good knowledge of cutting vinyl. If you are having any problems I should be able to help I have experienced most of them myself. I also have a supplier of high quality blanks. Any questions let me know,e-mail is vinylrecordcutting@tiscali.co.uk

I use a home-made vinyl cutting system(not made by myself). I am not an engineer but I have a good knowledge of cutting vinyl. If you are having any problems I should be able to help I have experienced most of them myself. I also have a supplier of high quality blanks. Any questions let me know,e-mail is vinylrecordcutting@tiscali.co.uk

Vinyl Manufacturing

Hi Andy (VinylFactory)

I am in process of setting up vinyl manufacturing and pressing factory in Europe.

Can you advise me where should I look for all equipment needed to start the production?

I have a good supplier base for vinyl raw material supply but the rest is still big question mark.

Thanks

Wojtaso

Hi Andy (VinylFactory)

I am in process of setting up vinyl manufacturing and pressing factory in Europe.

Can you advise me where should I look for all equipment needed to start the production?

I have a good supplier base for vinyl raw material supply but the rest is still big question mark.

Thanks

Wojtaso

vinyl record cutting

I do not press vinyl, I record music on to blank vinyl records by cutting a spiralling groove in to the record using an eliptical diamond.

I asked my supplier once where the best place to get vinyl pressing plant equipment was and he said Russia. He told me you could get second hand equipment for around 10000 euros(this was a couple of years ago). I think he said the biggest problem was transporting such bulky and heavy equipment.

I do not press vinyl, I record music on to blank vinyl records by cutting a spiralling groove in to the record using an eliptical diamond.

I asked my supplier once where the best place to get vinyl pressing plant equipment was and he said Russia. He told me you could get second hand equipment for around 10000 euros(this was a couple of years ago). I think he said the biggest problem was transporting such bulky and heavy equipment.

I've just been reading through this thread with the same (rather insane) idea as some other people.

After reading the thread, I still don't think I'm fully understanding how the cutter head works. Looking back at an old post by kalinski, are those diagrams of stereo cutter heads or mono cutter heads? I'm assuming if those diagrams are of stereo cutter heads, I'd need to feed the left channel to one coil and the right channel to the other coil.

-Adam

After reading the thread, I still don't think I'm fully understanding how the cutter head works. Looking back at an old post by kalinski, are those diagrams of stereo cutter heads or mono cutter heads? I'm assuming if those diagrams are of stereo cutter heads, I'd need to feed the left channel to one coil and the right channel to the other coil.

-Adam

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Vinyl Cutter, guidance needed :+)